Modified graphene oxide cement concrete early strength agent and application thereof

A technology of cement concrete and oxide stone, applied in the field of cement concrete early strength agent, can solve the problems affecting later strength, alkali aggregate reaction, corroded steel bars, etc., and achieve the effects of improving early strength, promoting early hydration process and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

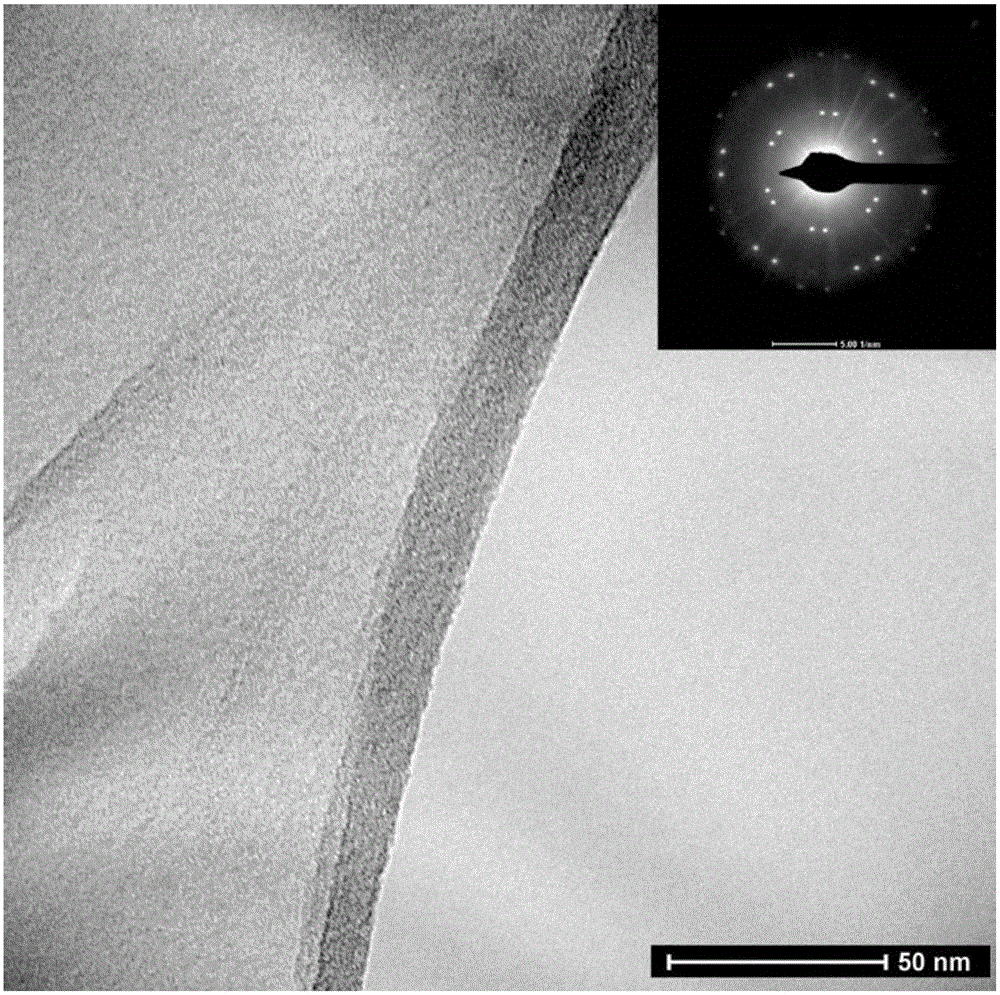

[0025] The size of the modified graphene oxide nanosheet is 0.5-2 μm, and the thickness is 0.8-1.6 nm. The microscopic morphology observed by transmission electron microscopy (TEM) is as follows: figure 1 shown. figure 1 Selected-area electron diffraction in the inset shows two sets of six-membered rings, representing a two-layer structure of graphene oxide in this region.

[0026] The modifier is a polycarboxylate superplasticizer with a mass fraction of 40%. The cement is PI52.5R Portland cement.

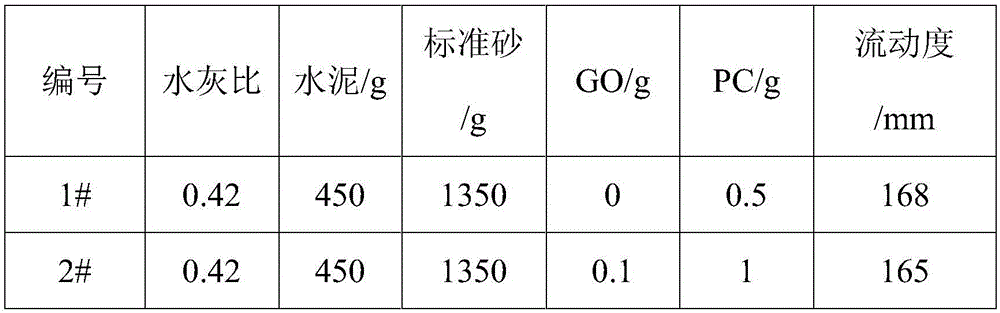

[0027] See Table 1 for the mixing ratio of comparative sample 1# and sample 2# to be tested in the present embodiment.

[0028] Table 1 1#, 2# cement mortar mix ratio

[0029]

[0030] (1) Preparation of GO

[0031] Add 1g of graphite powder into a three-necked flask, add 23ml of 98%wt concentrated sulfuric acid, stir in an ice-water bath at 0°C for 15mins; add 1g of NaNO to the mixed solution 3 (purity ≥ 99.0%), slowly add 3g potassium permanganate (purity ≥ 99.5%) after...

Embodiment 2

[0039] The size of the modified graphene oxide nanosheet is 0.5-2 μm, and the thickness is 0.8-1.6 nm. The microstructure observed by transmission electron microscopy (TEM) is as follows: figure 1 shown. figure 1 Selected-area electron diffraction in the inset shows two sets of six-membered rings, representing a two-layer structure of graphene oxide in this region.

[0040] The modifier is a polycarboxylate superplasticizer with a mass fraction of 40%. The cement used in this example is PI52.5R Portland cement.

[0041] See Table 2 for the mixing ratio of comparative sample 1# and test sample 2# in the present embodiment.

[0042] Table 2 1#, 2# cement mortar mix ratio

[0043]

[0044] (1) The preparation process of GO is the same as in Example 1.

[0045] (2) Modification of GO

[0046] The dosage of modifier PC is determined according to the water-cement ratio of cement mortar and the content of GO.

[0047] Weigh 0.05 g of dried graphene oxide with a high-precisi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com