Preparation method of lightweight self-insulating block containing waste brick particles and waste foam

A technology for self-insulating blocks and waste bricks, which is applied in ceramic products, solid waste management, sustainable waste treatment, etc., can solve the problems that the external wall foam waste insulation board cannot be processed, the lightweight aggregate cannot be used, etc., and achieves low prices. , the equipment requirements are low, the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

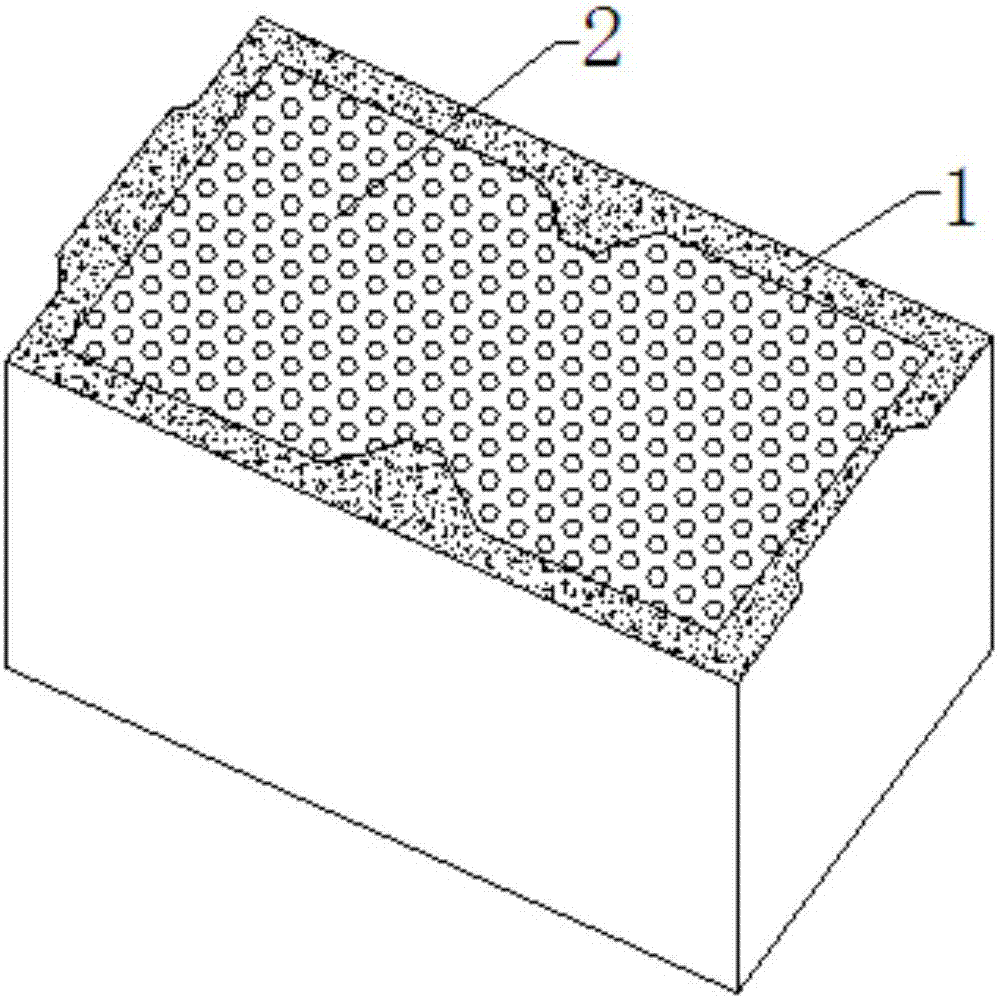

[0020] A method for preparing a lightweight self-insulating block containing waste brick particles and waste foam. The self-insulating block includes: a cavity module 1 and an insulating block 2 arranged in the cavity module 1. The preparation method includes the following steps :

[0021] (1) Break waste bricks into granular regenerated coarse aggregates below 10mm, break waste concrete blocks into recycled fine aggregates below 5mm, and break waste foam into foam particles below 10mm; Waste building bricks other than made bricks, waste foam is polystyrene material or extruded foam material;

[0022] (2) Mix recycled coarse aggregate, recycled fine aggregate, ordinary Portland cement and water at a mass ratio of 1:1:0.35:0.3 to obtain a four-mixture, and mold the above-mentioned four-mixture under a molding pressure of 100T Intermediate pressing 5S, demoulding to form cavity module 1;

[0023] (3) Mix 42.5 ordinary Portland cement, Class II fly ash, foam particles, liquid q...

Embodiment 2

[0026] A method for preparing a lightweight self-insulating block containing waste brick particles and waste foam. The self-insulating block includes: a cavity module and an insulating block arranged in the cavity module. The preparation method includes the following steps:

[0027] (1) Break waste bricks into granular regenerated coarse aggregates below 10mm, break waste concrete blocks into recycled fine aggregates below 5mm, and break waste foam into foam particles below 10mm; Waste building bricks other than made bricks, waste foam is polystyrene material or extruded foam material;

[0028] (2) Mix the recycled coarse aggregate, recycled fine aggregate, 42.5 ordinary Portland cement and water at a mass ratio of 1:0.5:0.15:0.15 (3min) to obtain a four-mixture, and mold the above-mentioned four-mixture at 100T Press 5S in the mold under pressure, demoulding to form a cavity module;

[0029](3) Mix 42.5 ordinary Portland cement, Class II fly ash, foam particles, liquid quick...

Embodiment 3

[0032] A method for preparing a lightweight self-insulating block containing waste brick particles and waste foam. The self-insulating block includes: a cavity module and an insulating block arranged in the cavity module. The preparation method includes the following steps:

[0033] (1) Break waste bricks into granular regenerated coarse aggregates below 10mm, break waste concrete blocks into recycled fine aggregates below 5mm, and break waste foam into foam particles below 10mm; Abandoned building bricks other than made bricks, waste foam is polystyrene material or extruded foam material;

[0034] (2) Mix the recycled coarse aggregate, recycled fine aggregate, 42.5 ordinary Portland cement and water at a mass ratio of 1:0.5:0.35:0.20 (3min) to obtain a four-mixture, and mold the above-mentioned four-mixture at 80T Pressing 5S in the mold under pressure, demoulding to form a cavity module;

[0035] (3) Mix 42.5 ordinary Portland cement, Class II fly ash, foam particles, liqui...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com