Concrete containing machine-processed gravel powder and dust collection stone powder and preparation method thereof

A technology for sand and gravel powder and concrete, applied in the field of concrete, can solve the problems of difficulty in quality control of concrete production, little application of dust-collecting stone powder, large fluctuation of moisture content, etc. Simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

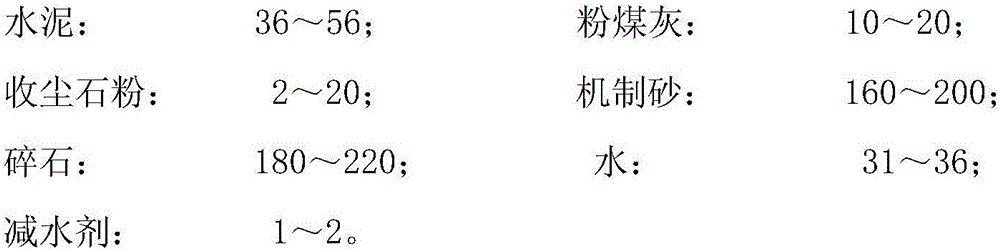

[0027] Embodiment 1: a kind of concrete containing machine-made sandstone powder and dust collection stone powder, it comprises the raw material of following weight portion:

[0028]

[0029] Wherein, the cement adopts 42.5 grade ordinary Portland cement; the fly ash is F class II grade fly ash, and the particle size of the crushed stone is 5-31.5mm continuous gradation; the dust-collecting stone powder is sand The fine powder collected by the stone factory in aggregate production, with a particle size of ≤0.075mm; the machine-made sand is rock particles with a particle size of less than 4.75mm obtained after mechanical crushing of pebble gravel, which contains 10-20% of Stone powder with a diameter of less than 0.075mm, the water content of the machine-made sand is 1.5%; the water reducing agent is polycarboxylate high-efficiency water reducing agent, and the water reducing rate is 30%.

[0030] The above-mentioned preparation method of concrete containing machine-made san...

Embodiment 2

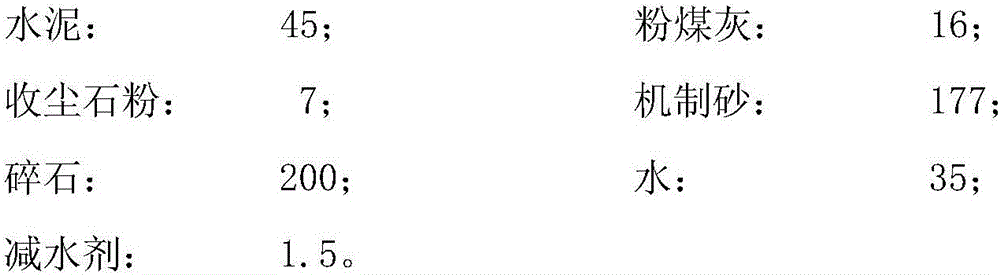

[0034] Embodiment 2: a kind of concrete containing machine-made sandstone powder and dust-collecting stone powder, it comprises the raw material of following weight portion:

[0035]

[0036] Wherein, the cement adopts 42.5R grade ordinary Portland cement; the fly ash is class F class II fly ash, and the particle size of the crushed stone is 5-31.5mm continuous gradation; the dust-collecting stone powder is The fine powder collected by the sand and gravel plant in the production of aggregates, the particle size is ≤0.075mm; the machine-made sand is the rock particles with a particle size of less than 4.75mm obtained after mechanical crushing of pebble gravel, which contains 10-20% For stone powder with a particle size of less than 0.075mm, the water content of the machine-made sand is 2.5%; the water reducing agent is a polycarboxylic acid high-efficiency water reducing agent, and the water reducing rate is 30%.

[0037] The above-mentioned preparation method of concrete co...

Embodiment 3

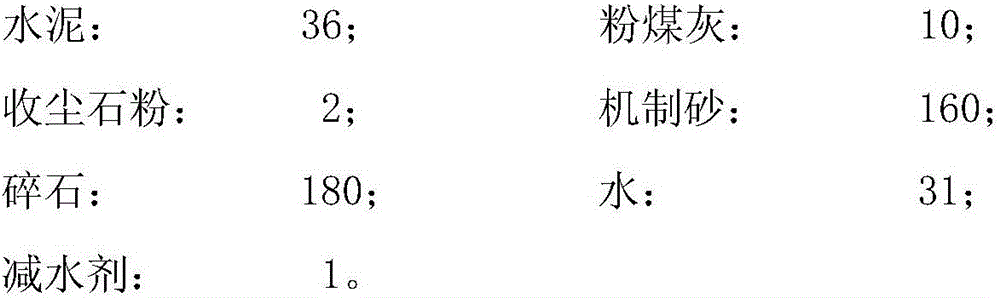

[0041] Embodiment 3: a kind of concrete containing machine-made gravel powder and dust-collecting stone powder, it comprises the raw material of following weight portion:

[0042]

[0043] Wherein, the cement adopts 42.5 grade ordinary Portland cement; the fly ash is F class II grade fly ash, and the particle size of the crushed stone is 5-31.5mm continuous gradation; the dust-collecting stone powder is sand The fine powder collected by the stone factory in aggregate production, with a particle size of ≤0.075mm; the machine-made sand is rock particles with a particle size of less than 4.75mm obtained after mechanical crushing of pebble gravel, which contains 10-20% of Stone powder with a diameter of less than 0.075mm, the water content of the machine-made sand is 1.8%; the water reducing agent is a polycarboxylate high-efficiency water reducing agent, and the water reducing rate is 30%.

[0044] The above-mentioned preparation method of concrete containing machine-made sand...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com