Flavone and lignin compound and extracting method thereof

An extraction method and compound technology, applied in organic chemistry and other fields, can solve the problems of unreported chemical composition research and achieve the effects of rich structure types, high purity, and little impact on the ecological environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The preparation method of the flavonoid lignans mixture of the present invention is as follows:

[0024] Collect the aboveground part of the weeping grass, dry it in the shade and crush it, and pass it through a 100-mesh sieve to get a fine powder. Take 11.8kg of fine powder and soak it in 3 times of methanol solution at room temperature for 3 times, successively for 3 days, 3 days and 7 days, and distill under reduced pressure to obtain about 980g of crude extract.

[0025] The crude extract was dissolved in 500 mL of water and then extracted three times with ethyl acetate in a volume ratio (1:1) to obtain 190 g of the ethyl acetate phase.

[0026] The ethyl acetate part passed through a macroporous resin (HP-20, Mitsubishi Chemical Corporation), the eluent was methanol-water, the volume ratios were: 30%, 50%, 80%, methanol, 9 L each. Wherein 80% methanol was partially concentrated under reduced pressure and dried in the shade to obtain 40 g.

[0027] Ethyl acetate 8...

Embodiment 2

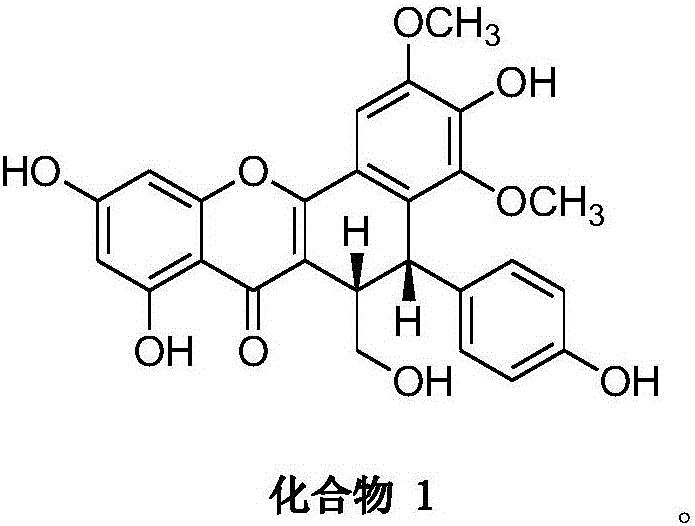

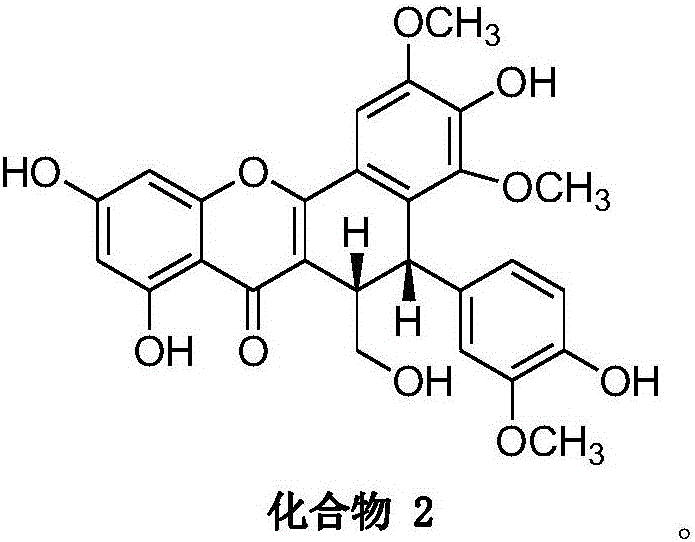

[0030] The preparation method of compound 1 and 2 of the present invention is as follows:

[0031] The Fr.3d part (12 g) was shaken and washed with 20 mL of methanol solution, the washing solution was concentrated under reduced pressure to obtain Fr.3dr (2 g), and the remaining part was dried in the shade to obtain Fr.3dc.

[0032] Part of the Fr.3dr sample (0.3 g) was subjected to Sephadex LH-20 (Sephadex LH-20, Amersham Pharmacia Biotech) column chromatography with methanol as the eluent (200 mL) to remove the compound alfalfalin (20 mg). The remaining parts were combined and purified by silica gel column chromatography with chloroform / methanol=10:1 as the eluent, after being dissolved in methanol, passed through Waters 1525 high performance liquid chromatography, the chromatographic solvents were water and acetonitrile, and the chromatographic conditions were: 25% Acetonitrile isocratic, flow rate: 2mL / min, detection wavelength: 340nm, compound 1 (4mg, retention time: 15.9m...

Embodiment 3

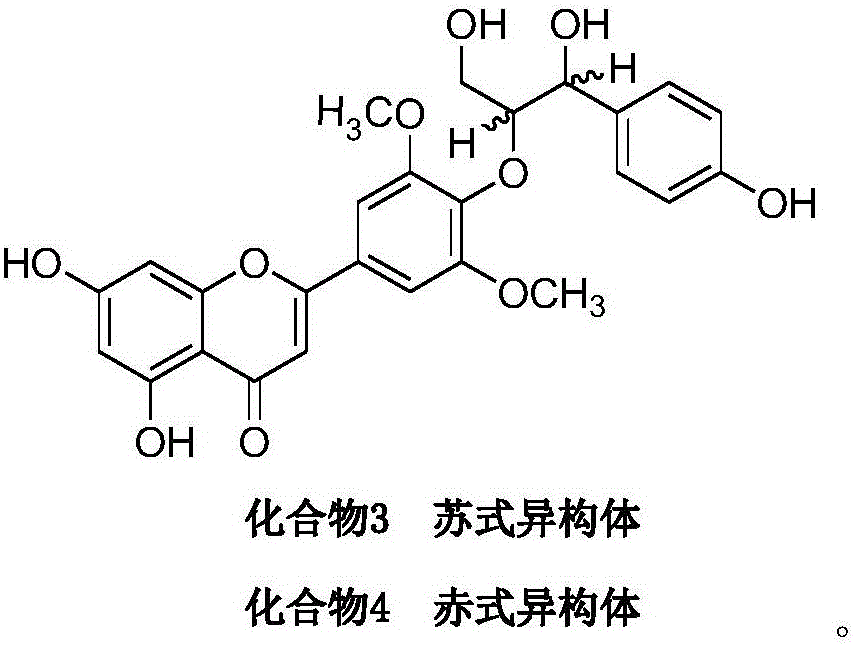

[0041] The preparation method of compound 3-6 of the present invention is as follows:

[0042] The Fr.3d part (12g) was shaken and washed with 20mL of methanol solution, the washing solution was concentrated under reduced pressure to obtain Fr.3dr (2g), and the remaining insoluble part was dried in the shade to obtain Fr.3dc.

[0043] Get Fr.3dc (10g) by reverse phase (RP-C 18 , Mitsubishi Chemical Corporation), the eluent is acetone / water (volume ratio: 30%, 50%, 70%, 90%), each 2L. The 30% and 50% parts are Fr.3dc1, the 70% part is Fr.3bc2, the 90% part is Fr.3dc3, and the acetone part is Fr.3dc4.

[0044] The Fr.3dc2 part was subjected to silica gel column chromatography with chloroform:methanol, the volume ratio was 20:1, 10:1, 5:1, 300 mL each, gradient elution. Get chloroform: methanol (10:1) part, adopt 20cm * 20cm to prepare silica gel plate, chloroform / methanol=10:1 is eluent, obtain two parts, utilize Sephadex LH-20 column chromatography (with chloroform / methanol r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com