Solvent type acrylate pressure-sensitive adhesive preparation method

A technology of acrylate and pressure-sensitive adhesives, which is applied in the direction of adhesive types, ester copolymer adhesives, etc., and can solve problems such as low molecular weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

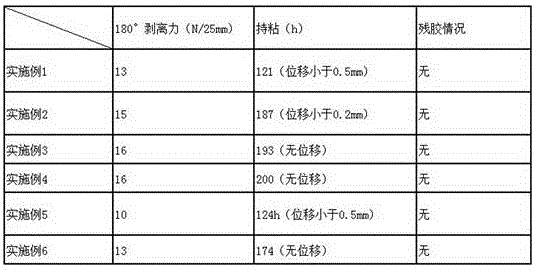

Examples

Embodiment 1

[0033] 1) First mix 32.8% isooctyl acrylate, 13.3% methyl acrylate, 1.6% maleic anhydride, 0.5% hydroxyethyl acrylate, and 3.2% vinyl acetate, then take 1 / 2 of it and 1 / 2 of all acrylic acid 2.1% 3. Weigh 1 / 2 of 16.6% ethyl acetate and 23.3% of all cyclohexane and mix them in a beaker. Then pour it into a flask equipped with a stirring device, a thermometer and a condenser, gradually heat it to 78°C, and then add 1 / 3 of 0.3% of the total initiator into the flask to start the reaction.

[0034] 2) Pay attention to observe that when small bubbles appear on the reaction liquid surface, start timing for 1 hour. After 1 hour of reaction, 1 / 3 of the total initiator AIBN and 1 / 3 of the total acrylic acid are evenly added dropwise into the reaction system through a constant pressure funnel, of which AIBN was added dropwise ten times within 90 minutes, and acrylic acid was added dropwise five times within 40 minutes. After the dropwise addition was completed, keep warm for 1-2 hours. ...

Embodiment 2

[0040] 1) First mix 32.8% isooctyl acrylate, 13.3% methyl acrylate, 1.6% maleic anhydride, 0.5% hydroxyethyl acrylate, 3.2% vinyl acetate, and 0.03% epoxy acrylate, then take 1 / 2 and 1 / 3 of 2.1% of all acrylic acid, 16.6% of ethyl acetate and 1 / 2 of 23.3% of all cyclohexane were weighed and mixed in a beaker. Then pour it into a flask equipped with a stirring device, a thermometer and a condenser, gradually heat it to 78°C, and then add 1 / 3 of 0.3% of the total initiator into the flask to start the reaction.

[0041]2) Pay attention to observe that when small bubbles appear on the reaction liquid surface, start timing for 1 hour. After 1 hour of reaction, 1 / 3 of the total initiator AIBN and 1 / 3 of the total acrylic acid are evenly added dropwise into the reaction system through a constant pressure funnel, of which AIBN was added dropwise ten times within 90 minutes, and acrylic acid was added dropwise five times within 40 minutes. After the dropwise addition was completed, kee...

Embodiment 3

[0047] 1) First mix 32.8% isooctyl acrylate, 13.3% methyl acrylate, 1.6% maleic anhydride, 0.5% hydroxyethyl acrylate, 3.2% vinyl acetate, and 0.05% epoxy acrylate, then take 1 / 2 and 1 / 3 of 2.1% of all acrylic acid, 16.6% of ethyl acetate and 1 / 2 of 23.3% of all cyclohexane were weighed and mixed in a beaker. Then pour it into a flask equipped with a stirring device, a thermometer and a condenser, gradually heat it to 78°C, and then add 1 / 3 of 0.3% of the total initiator into the flask to start the reaction.

[0048] 2) Pay attention to observe that when small bubbles appear on the reaction liquid surface, start timing for 1 hour. After 1 hour of reaction, 1 / 3 of the total initiator AIBN and 1 / 3 of the total acrylic acid are evenly added dropwise into the reaction system through a constant pressure funnel, of which AIBN was added dropwise ten times within 90 minutes, and acrylic acid was added dropwise five times within 40 minutes. After the dropwise addition was completed, ke...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Peel force | aaaaa | aaaaa |

| Peel force | aaaaa | aaaaa |

| Peel force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap