Underpainting composition for woodware and its preparation method and coating process

A composition and woodware technology, applied in multi-color effect paints, coatings, polyester coatings, etc., can solve the problems of discount of plate construction effect, uneven background color, uneven coating thickness, etc., to facilitate process application , Improve the quality of painting, the effect of clear texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

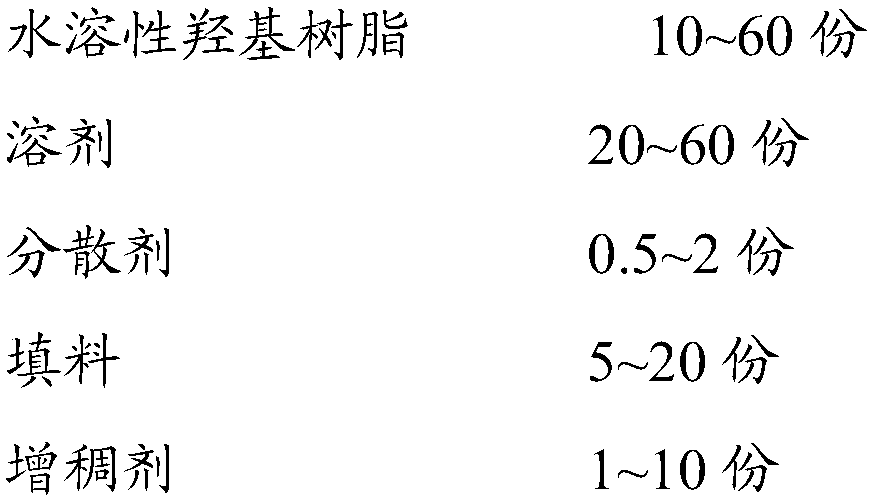

[0039] Embodiment 1 A kind of primer color composition for woodware, in parts by weight, includes the following raw material components:

[0040]

[0041] The molar percentage of hydroxyl groups in the water-soluble hydroxyl resin is 6.8%, which is a modified water-soluble alkyd resin sol 30 purchased from Worlee, Germany.

[0042] The solvent is DPM.

[0043] The dispersant is a high molecular weight modified acrylic copolymer, purchased from Cytec Corporation's VXW6208 / 60.

[0044] The filler is transparent powder.

[0045] The thickener is bentonite.

[0046] The anti-skinning agent is butanone oxime.

[0047] The preparation method of the above-mentioned base paint composition for woodware comprises the following steps:

[0048] In the water-soluble hydroxyl resin, add part of the solvent to adjust the viscosity of the mixture to 320mpa.s, then add the dispersant, and stir at a low speed of 500 rpm for 10 minutes;

[0049] Then add the filler and the toner in seque...

Embodiment 2

[0056] Embodiment 2 A kind of base paint composition for woodware, in parts by weight, includes the following raw material components:

[0057]

[0058] The molar percentage of hydroxyl groups in the water-soluble hydroxyl resin is 8.6%, which is a modified water-soluble alkyd resin sol 30 purchased from Worlee, Germany.

[0059] The solvent is DPM.

[0060] The dispersant is a high molecular weight modified acrylic copolymer, purchased from Cytec Corporation's VXW6208 / 60.

[0061] The filler is transparent powder.

[0062] The thickener is fumed silica.

[0063]The anti-skinning agent is butanone oxime.

[0064] The preparation method of the above-mentioned base paint composition for woodware comprises the following steps:

[0065] In the water-soluble hydroxyl resin, add part of the solvent to adjust the viscosity of the mixture to 350mpa.s, then add the dispersant, and stir at a low speed of 600 rpm for 10 minutes;

[0066] Then add the filler and the toner in seque...

Embodiment 3

[0073] Embodiment 3 A kind of base paint composition for woodware, in parts by weight, includes the following raw material components:

[0074]

[0075]

[0076] The molar percentage of hydroxyl groups in the water-soluble hydroxyl resin is 8.6%, which is a modified water-soluble alkyd resin sol 30 purchased from Worlee, Germany.

[0077] The solvent is a mixture of DPM and alkanes.

[0078] The dispersant is a high molecular weight modified acrylic copolymer, purchased from Cytec Corporation's VXW6208 / 60.

[0079] The filler is talcum powder.

[0080] The thickener is polyamide wax.

[0081] The anti-skinning agent is butanone oxime.

[0082] The preparation method of the above-mentioned base paint composition for woodware comprises the following steps:

[0083] In the water-soluble hydroxyl resin, add part of the solvent to adjust the viscosity of the mixture to 250mpa.s, then add the dispersant, and stir at a low speed of 500 rpm for 5 minutes;

[0084] Then add ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com