Waterborne two-component setting water for solid wood and preparation method of setting water

A water-based two-component, setting water technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problems of excessive VOC content of toxic and harmful substances, wood expansion, bending, large deformation, poor sealing effect, etc., to achieve VOC Effect of less emission, prevention of cracking, and avoidance of paint film depression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

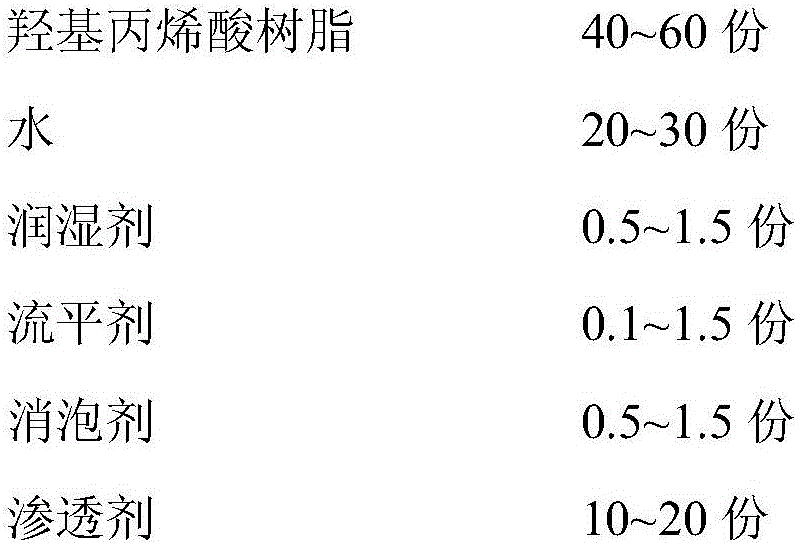

Embodiment 1

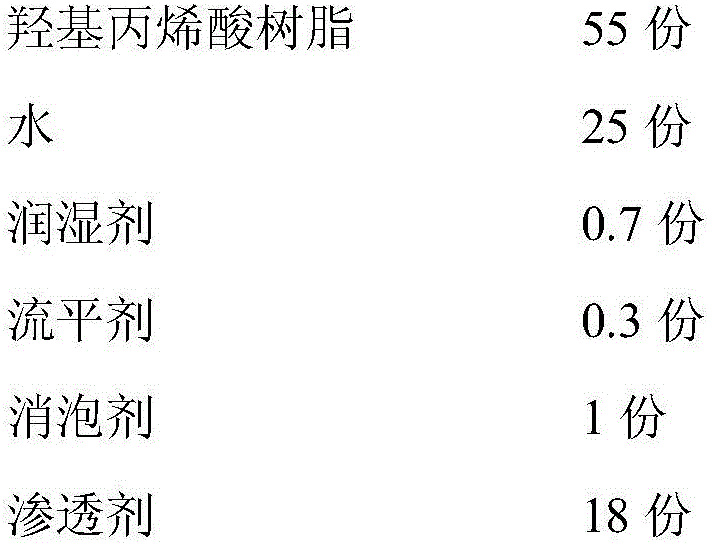

[0032] According to the weight ratio, mix 55 parts of hydroxyl acrylic resin, 25 parts of water, 0.7 parts of Hemings Disponer W-920, 0.3 parts of Hemings SLIS-AYD FS444, 1 part of BYK-093, and 18 parts of penetrant, and then mix according to the mixture Mix with water-based isocyanate at a weight ratio of 5:1 to obtain water-based two-component solid wood styling water.

Embodiment 2

[0034] According to the weight ratio, mix 60 parts of hydroxyl acrylic resin, 30 parts of water, 1.5 parts of Hemings Disponer W-920, 1.5 parts of Hemings SLIS-AYD FS444, 1.5 parts of BYK-093, and 20 parts of penetrant, and then mix according to the mixture and The weight ratio of water-based isocyanate is 5:1, and the water-based two-component solid wood styling water can be obtained.

Embodiment 3

[0036] Mix 40 parts of hydroxyl acrylic resin, 15 parts of water, 0.8 parts of Hemings Disponer W-9200, 0.8 parts of BYK-342, 22 parts of defoamer BYK-02, and 15 parts of penetrant according to the weight ratio, and then mix the mixture with water-based isocyanate The weight ratio is 5:1 to get water-based two-component solid wood styling water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com