Extraction process of chlortetracycline premixed agent

An extraction process, the technology of chlortetracycline, applied in the field of extraction process of high-content chlortetracycline premix, can solve the problems of low content of biologically active components, increased sewage treatment costs, high potency of chlortetracycline, etc., to achieve increased yield High efficiency, reduced sewage treatment cost, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

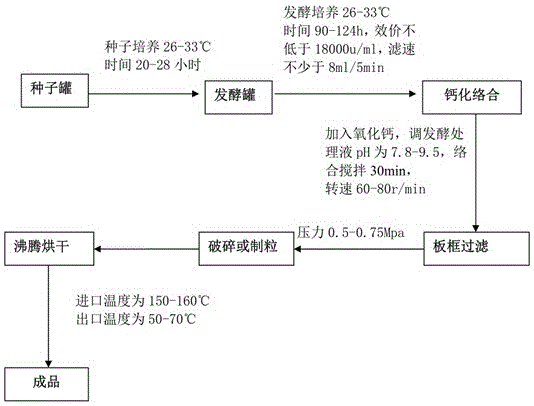

Method used

Image

Examples

Embodiment 1

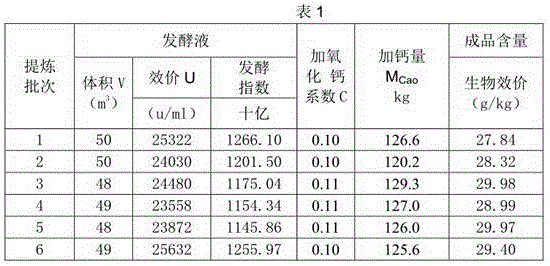

[0037] Embodiment one, get aureomycin and put tank fermented liquid 90m 3 , divided into 2 equal volumes.

[0038] One group: take one part of aureomycin and put it in a tank for 45m fermentation liquid 3 , use the calculation formula to calculate the amount of calcium oxide added, add calcium oxide under normal temperature conditions, the pH of the fermentation treatment solution is 7.8, stir for 30 minutes, and the speed is 60-80 r / min to obtain the calcification complex solution; the calcification complex solution Plate and frame filtration, the pressure is controlled at 0.5-0.75Mpa; the filter cake obtained after filtration is crushed; the crushed particles are boiled and dried, the inlet temperature is controlled at 150-160°C, and the outlet temperature is 50-70°C to obtain aureomycin Finished premix.

[0039]One group of control group: take another aureomycin and put the fermented liquid in a tank for 45m 3 , directly add calcium carbonate equivalent to 5% of the volu...

Embodiment 2

[0040] Embodiment two, get aureomycin and put tank fermented liquid 89m 3 , divided into 2 equal volumes.

[0041] The second group: take one part of aureomycin and put it in a tank to ferment 44.5m 3 , Calculate the amount of calcium oxide added with the calculation formula, add calcium oxide under normal temperature conditions, the pH of the fermentation treatment solution is 8.5, and the other extraction processes are the same as the first group.

[0042] Two groups of control groups: take another chlortetracycline and put the fermentation liquid in a tank of 44.5m 3 , directly add calcium carbonate equivalent to 5% of the volume of the fermentation broth at room temperature, and other extraction processes are the same as a group of control groups.

Embodiment 3

[0043] Embodiment three, get aureomycin and put tank fermented liquid 91m 3 , divided into 2 equal volumes.

[0044] Three groups: take one part of aureomycin and put it in a tank for 45.5m fermentation broth 3 , Calculate the amount of calcium oxide added with the calculation formula, add calcium oxide under normal temperature conditions, the pH of the fermentation treatment solution is 9.0, and the other extraction processes are the same as the first group.

[0045] Three groups of control groups: take another 45.5m 3 , directly add calcium carbonate equivalent to 6% of the volume of the fermentation broth at room temperature, and other extraction processes are the same as a group of control groups.

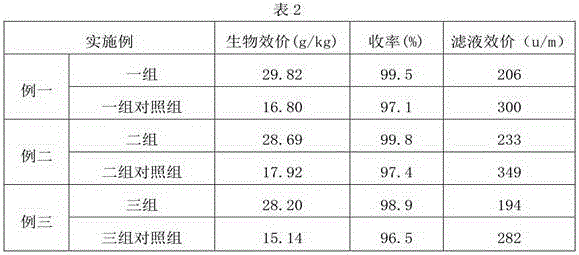

[0046] The test results obtained by the three examples are shown in Table 2.

[0047]

[0048] As can be seen from the above implementation comparison, the present invention improves the production process, and calcium oxide can be used as a pH regulator to make the ferme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com