Preparation process for metal matrix material for petroleum sleeve

A technology of metal matrix and oil casing, applied in the direction of casing, manufacturing tools, drilling pipes, etc., can solve the problem that alloy materials cannot meet the cost and strength at the same time, and achieve the effect of low raw material cost and production cost and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

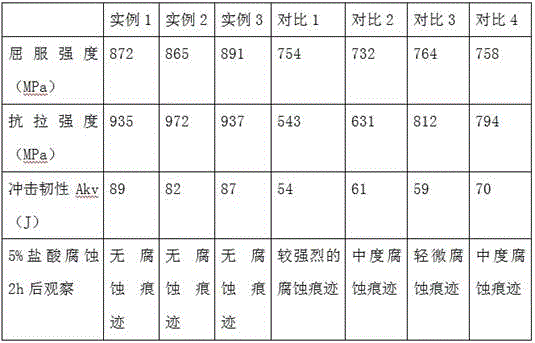

Examples

Embodiment

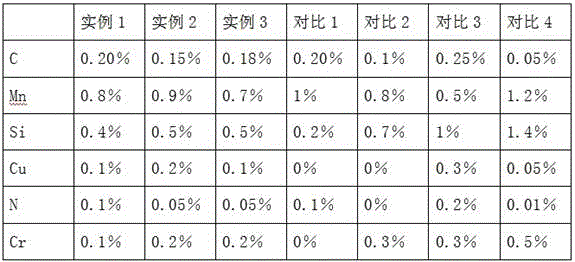

[0020] The preparation process of metal matrix material for oil casing pipe includes:

[0021] Step 1. Put the pig iron into the furnace and melt it as an iron matrix, and undergo desulfurization, deoxidation, and dephosphorization treatments to make the sulfur content in the pig iron less than 0.02% and the phosphorus content less than 0.03%;

[0022] Step 2: After adding Mn, Cu, N to the iron matrix and mixing uniformly, heat to a molten state and keep it for 1 to 2 hours, then add Si, Cr, and C to mix uniformly, and keep it at 800-1100℃ for at least 2h After that, increase the temperature to 1200-1250℃ at a heating rate of 5-10℃ / min, keep it for at least 2h, and then cast at a constant temperature at 800-850℃;

[0023] Step 3. After the casting is completed, reduce the temperature to 400-450°C at a rate of 5-10°C / min, and then quickly cool to below 200°C; the rapid cooling rate is greater than 100°C / min;

[0024] Step 4: After cooling, put it into a furnace fire at 800-850°C for 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com