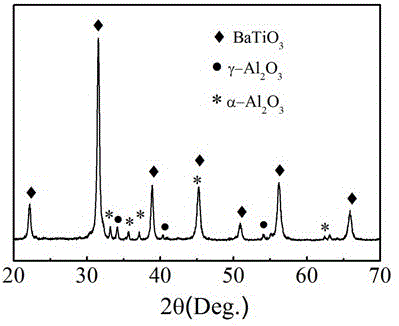

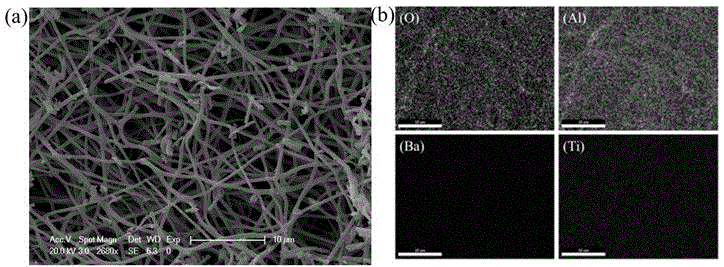

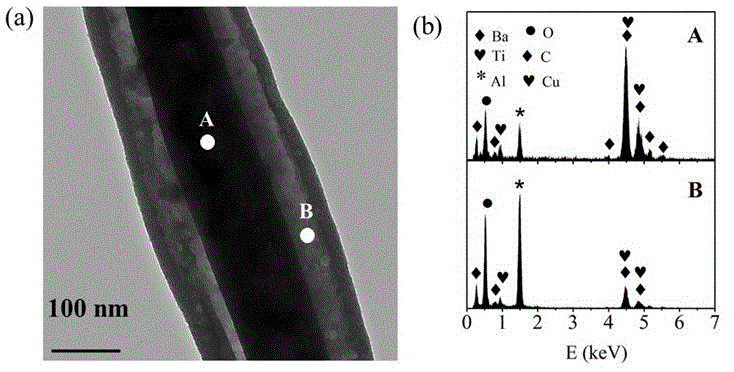

Method for preparing one-dimensional core-shell structure BaTiO3@Al2O3 by means of one-step synthesis

A technology of core-shell structure and footwork, applied in fiber processing, fiber chemical characteristics, filament/thread forming, etc., can solve the problems of difficult control of core-shell thickness ratio and shell thickness uniformity, etc., to achieve The effect of controllable thickness, low preparation cost and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 1. Weigh Ba(COOH) according to the molar ratio Ba:Ti=1:1 2 、C 16 h 36 o 4 Ti. Ba(COOH) 2 Soluble in CH 3 CH 2 In the COOH solution, the mass ratio of the two is 1:3.2, sonicate for 30 minutes, and then magnetically stir for 30 minutes at a temperature of 40-80°C until Ba(COOH) 2 completely dissolved in CH 3 CH 2 In COOH, the obtained solution A was left at room temperature for 0.8 h; the C 16 h 36 o 4 Ti joins acetylacetone (C 5 h 8 o 2 ), wherein the mass ratio of the two is 1:1.7, then magnetically stirred at room temperature for 0.8 h, and the resulting solution B was left to stand at room temperature for 0.8 h; PVP was added to ethanol (CH 3 CH 2 OH), the mass ratio of the two was 1:1.8, and then magnetically stirred at 35°C for 30 min until PVP was completely dissolved in CH 3 CH 2 In OH, the obtained solution C was left to stand at room temperature for 0.8 h; the three groups of solutions A, B, and C were mixed according to the mass ratio of 1:1:2...

Embodiment 2

[0028] 1. Weigh Ba(COOH) according to the molar ratio Ba:Ti=1:1 2 、C 16 h 36 o 4 Ti. Ba(COOH) 2 Soluble in CH 3 CH 2 In the COOH solution, the mass ratio of the two was 1:3, sonicated for 30 min, and then magnetically stirred at 40 °C for 30 min until Ba(COOH) 2 completely dissolved in CH 3 CH 2 COOH, the resulting solution A was left at room temperature for 0.5 h; the C 16 h 36 o 4 Ti joins acetylacetone (C 5 h 8 o 2 ), where the mass ratio of the two is 1:1.5, then magnetically stirred at room temperature for 0.5 h, and the resulting solution B was left to stand at room temperature for 0.5 h; PVP was added to ethanol (CH 3 CH 2 OH), the mass ratio of the two is 1:1.5, and then magnetically stirred at 30 °C for 30 min until the PVP is completely dissolved in CH 3 CH 2 OH, the obtained solution C was left to stand at room temperature for 0.5 h; the three groups of solutions A, B, and C were mixed in a mass ratio of 1:1:2, and magnetically stirred at room tempe...

Embodiment 3

[0032] 1. Weigh Ba(COOH) according to the molar ratio Ba:Ti=1:1 2 、C 16 h 36 o 4 Ti. Ba(COOH) 2 Soluble in CH 3 CH 2 In the COOH solution, the mass ratio of the two was 1:5, sonicated for 30 min, and then magnetically stirred at 60 °C for 30 min until Ba(COOH) 2 completely dissolved in CH 3 CH 2 COOH, the resulting solution A was left at room temperature for 1.5 h; the C 16 h 36 o 4 Ti joins acetylacetone (C 5 h 8 o 2 ), where the mass ratio of the two was 1:2.5, and then magnetically stirred at room temperature for 1.5, and the resulting solution B was left to stand at room temperature for 2 h; PVP was added to ethanol (CH 3 CH 2 OH), the mass ratio of the two was 1:3, and then magnetically stirred at 60 °C for 30 min until the PVP was completely dissolved in CH 3 CH 2 OH, the obtained solution C was left at room temperature for 2 h; the three groups of solutions A, B, and C were mixed according to the mass ratio of 1:1:2, and magnetically stirred at room tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com