A refining process and device for viscose fiber

A technology of viscose fiber and refining equipment, which is applied in fiber processing, plant fiber, liquid/gas/steam fiber/sliver/roving processing, etc. It can solve the problems of easy corrosion of equipment, increase in material and labor costs, and achieve saving Artificial, keep the machine equipment and design arrangement, strengthen the effect of bleaching reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

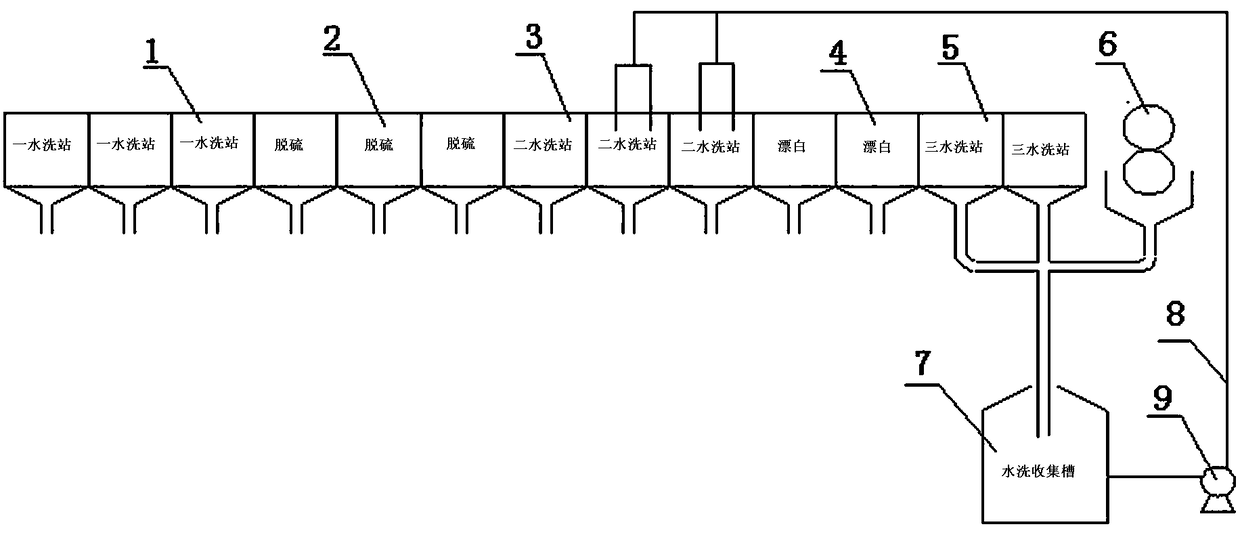

[0023] A refining process for viscose fiber, the process method is mainly to use NaOH to desulfurize viscose fiber, and then use H 2 O 2 Perform bleaching.

[0024] The process specifically includes the following steps:

[0025] A. Send the viscose fiber washed in the first water washing station to the desulfurization station, where NaOH is used for desulfurization, and the viscose fiber desulfurized by NaOH enters the second water washing station for washing;

[0026] B. Send the viscose fiber washed in the second washing station to the bleaching station, and use H in the bleaching station 2 O 2 Bleached, after H 2 O 2 The bleached viscose fiber enters the three-water washing station for washing.

[0027] Optimization process: the desulfurization temperature in step A is 85°C-90°C, preferably 85°C, and the bleaching temperature in step B is 60°C-65°C, preferably 62°C. Improve the reactivity of materials.

[0028] It also includes step C of transporting the return water from the three-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com