A kind of antistatic wear-resistant noise reduction sound insulation material and preparation method thereof

A sound insulation material, wear-resistant technology, applied in the direction of wear-resistant fibers, fiber processing, textiles and papermaking, etc. Peeling and scattering problems, to achieve the effect of light weight, outstanding wear resistance and antistatic properties, and easy preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

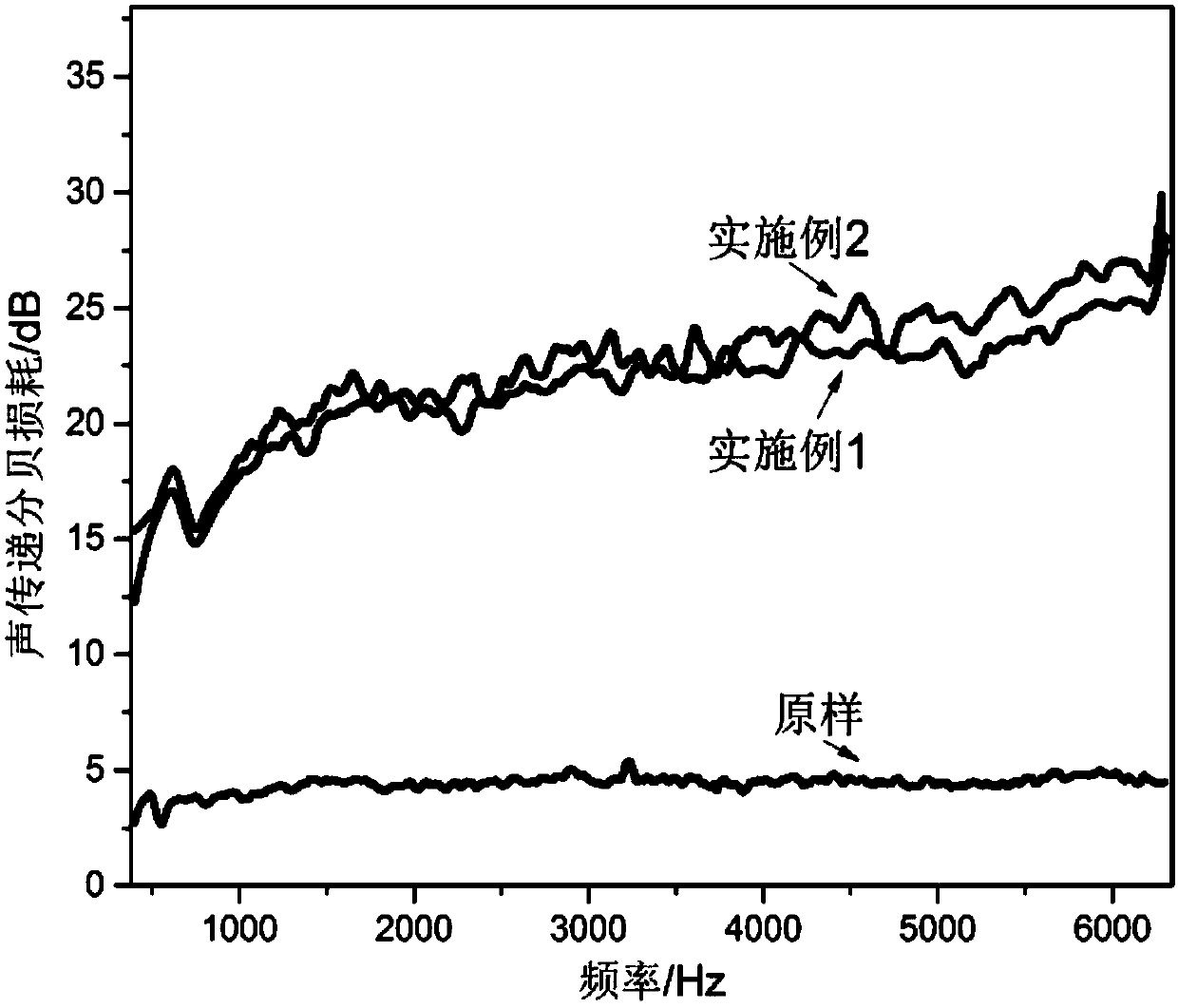

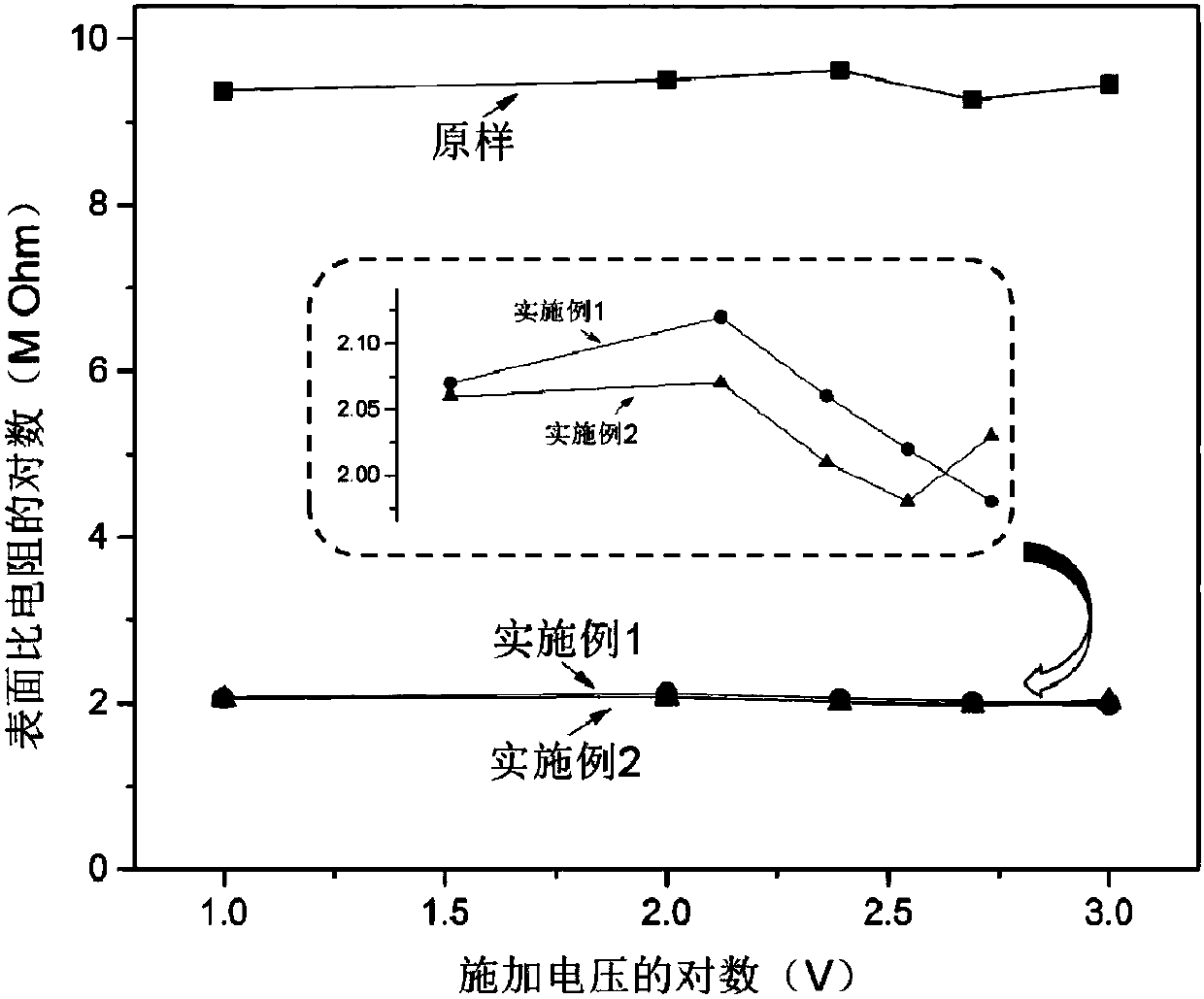

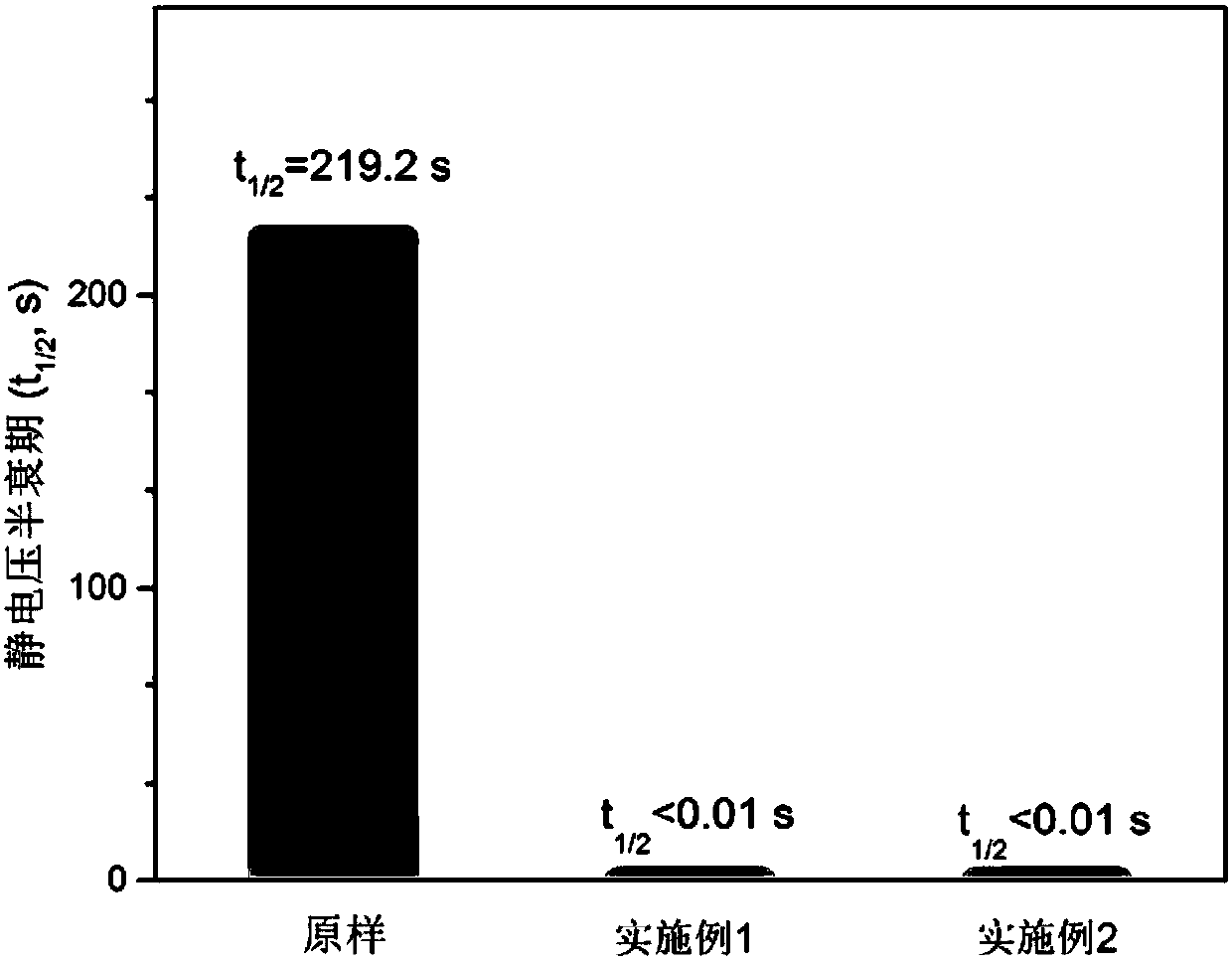

Embodiment 1

[0029] Step (1): under the condition of continuous stirring, slowly add the graphite powder into the water-based polyurethane solution, the addition ratio is 1.0% of the water-based polyurethane solution (if the water-based polyurethane is 100ml, then add 1.0g of the graphite powder); at the same time, Add a certain amount of sodium dodecylsulfonate as a dispersing aid, and the addition ratio is 0.5% of the graphite powder mass (such as adding 1.0g of graphite powder, the amount of sodium dodecylsulfonate added is 5mg), stir After 0.5h, a mixed solution was obtained.

[0030] Step (2): Wash the nonwoven fabric substrate with distilled water to remove surface impurities; then, perform alkali reduction treatment: the concentration of the alkali solution is 2%, the alkali reduction treatment time is 60 minutes, and the temperature condition is 80°C.

[0031] Step (3): Place the nonwoven material after the alkali reduction treatment in the graphite powder water-based polyurethane ...

Embodiment 2

[0033] Step (1): under the condition of continuous stirring, the graphite powder is slowly added in the water-based polyurethane solution, and the addition ratio is 2.0% of the water-based polyurethane solution (as the water-based polyurethane is 100ml, then add 2.0g of the graphite powder); meanwhile, Add a certain amount of sodium dodecyl sulfonate as a dispersing aid, and the addition ratio is 0.5% of the graphite powder mass (such as adding 2.0 g of graphite powder, the amount of sodium dodecyl sulfonate is 10 mg), stir 2h, a mixed solution was obtained.

[0034] Step (2): Wash the nonwoven fabric substrate with acetone solution to remove surface impurities; then, carry out alkali reduction treatment, the concentration of the alkali solution is 2%, the alkali reduction treatment time is 60min, and the temperature condition is 80°C.

[0035] Step (3): Place the nonwoven material after the alkali reduction treatment in the graphite powder water-based polyurethane mixed solut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com