Catalytic cracking regenerated flue gas sulfur transfer agent and preparation method thereof

A technology for regenerating flue gas and sulfur transfer agent, applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve the problems of increased raw material cost, high toxicity, expensive rare earth cerium, etc., and achieve high SOx adsorption. Ability, simple preparation and operation method, good regeneration performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

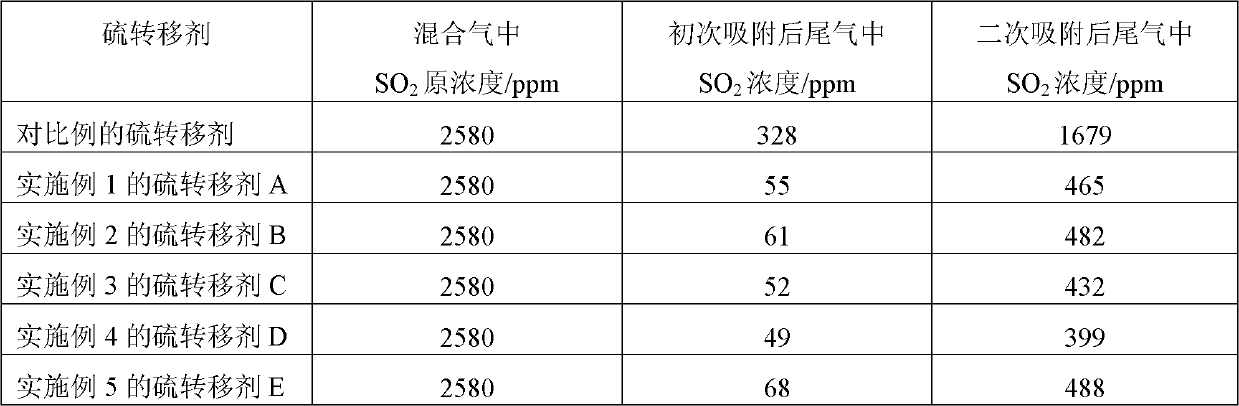

Examples

Embodiment 1

[0036] 43.1gMg(NO 3 ) 2 ·6H 2 O, 25.5gAl(NO 3 ) 3 9H 2 O, 4.8gFe(NO 3 ) 3 9H 2 O, 14.3gMnCl 2 4H 2 O and 200.0gH 2 O mixed and stirred to dissolve to form solution A; 26.2gNaOH, 4.6gNa 2 CO 3 and 200.0gH 2 O was mixed and stirred to dissolve to form solution B; under the condition of 80°C water bath, solution A was added dropwise to solution B with continuous stirring, the dropping time was 1 hour, and the dropping rate was about 3.3ml / min. Continue to stir for 3h after the dropwise addition, and crystallize at 80°C for 18h, keep the pH of the solution at 13, then cool, filter with suction, wash with deionized water until neutral, dry at 100°C for 6h, and roast at 700°C for 6h to obtain sulfur transfer Agent A.

Embodiment 2

[0038] 43.1gMg(NO 3 ) 2 ·6H 2 O, 25.5gAl(NO 3 ) 3 9H 2 O, 4.8gFe(NO 3 ) 3 9H 2 O, 14.3gMnCl 2 4H 2 O and 200.0gH 2 O mixed and stirred to dissolve to form solution A; 36.7gKOH, 4.2g (NH 4 ) 2 CO 3 and 200.0gH 2 O was mixed and stirred to dissolve to form solution B; under the condition of 80°C water bath, solution A was added dropwise to solution B with continuous stirring, the dropping time was 1 hour, and the dropping rate was about 3.3ml / min. Continue to stir for 3h after the dropwise addition, and crystallize at 80°C for 18h, keep the pH of the solution at 13, then cool, filter with suction, wash with deionized water until neutral, dry at 100°C for 6h, and roast at 700°C for 6h to obtain sulfur transfer Agent B.

Embodiment 3

[0040] 34.1gMgCl 2 ·6H 2 O, 16.4g AlCl 3 ·6H 2 O, 3.2gFeCl 3 ·6H 2 O, 14.3gMnCl 2 4H 2 O and 200.0gH 2 O mixed and stirred to dissolve to form solution A; 26.2gNaOH, 4.6gNa 2 CO 3 and 200.0gH 2 O was mixed and stirred to dissolve to form solution B; under the condition of 80°C water bath, solution A was added dropwise to solution B with continuous stirring, the dropping time was 1 hour, and the dropping rate was about 3.3ml / min. Continue to stir for 3h after the dropwise addition, and crystallize at 80°C for 18h, keep the pH of the solution at 13, then cool, filter with suction, wash with deionized water until neutral, dry at 100°C for 6h, and roast at 700°C for 6h to obtain sulfur transfer Agent C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com