ru-cu 2 o Wrapped cu nanowires and its preparation method and application

A technology of ru-cu2o and nanowires, applied in chemical instruments and methods, chemical/physical processes, light water/sewage treatment, etc., can solve difficult problems such as preparation, and achieve simple and easy operation methods, good application value, and comparative The effect of large surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

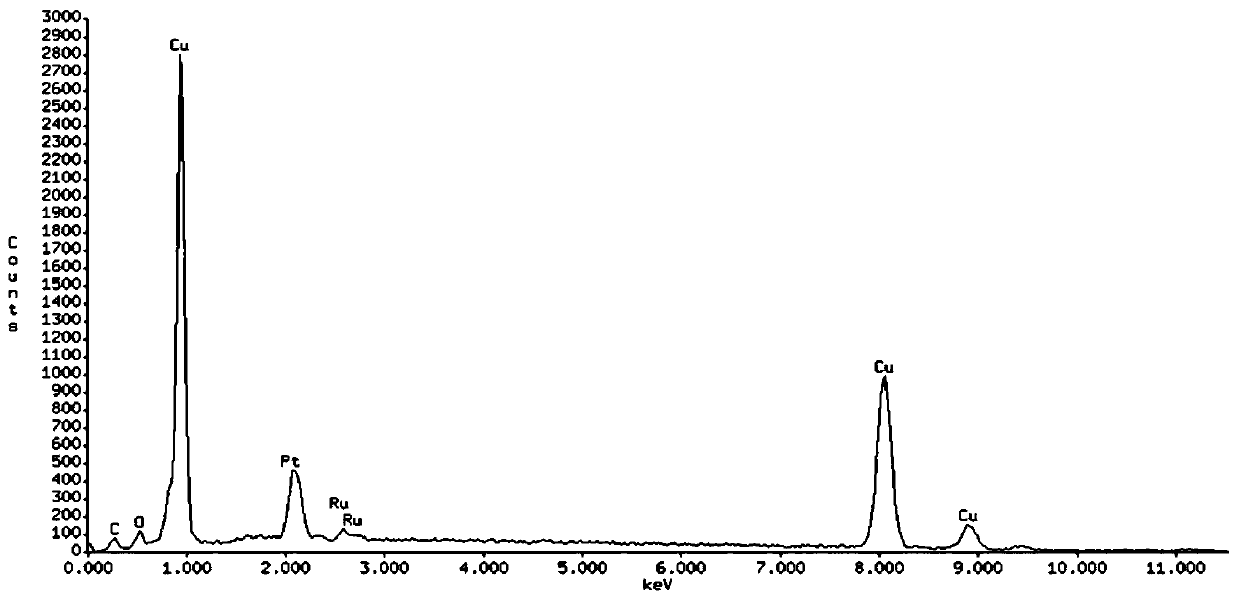

[0030] Preparation of Ru-Cu 2 O wrapped Cu nanowires

[0031] Add 120 mg of copper nanowires and 200 mL of deionized water to a round-bottomed flask, react in a water bath at 70°C for 6 hours, then cool to room temperature, filter, wash the filter cake with absolute ethanol and distilled water several times, and dry it in vacuo. Cu with a core-shell structure with an outer shell of a certain thickness 2 O is a nanowire with Cu as the core. Prepared Cu 2 Put 60 mg of nanowires with O as the shell and Cu as the core in a small beaker, slowly add 0.63 mL (38.2% by mass fraction) of ruthenium trichloride solution into the beaker, and let the mixture stand for 30 seconds after 1 min of dripping , the solution changed from the previous light yellow to light gray, and the precipitate was separated by centrifugation, washed several times with absolute ethanol and deionized water, and dried to obtain Ru-Cu with a mass fraction of Ru doped at 2%. 2 O wrapped Cu nanowires.

[0032] ...

Embodiment 2

[0034] Preparation of Ru-Cu 2 O wrapped Cu nanowires

[0035] Add 120 mg of copper nanowires and 200 mL of deionized water to a round-bottomed flask, react in a water bath at 70°C for 6 hours, then cool to room temperature, filter, wash the filter cake with absolute ethanol and distilled water several times, and dry it in vacuo. Cu with a core-shell structure with an outer shell of a certain thickness 2 O is a nanowire with Cu as the core. Prepared Cu 2 Put 60 mg of nanowires with O as the shell and Cu as the core in a small beaker, slowly add 1.26 mL (mass fraction of 38.2%) ruthenium trichloride solution into the beaker, and let the mixture stand for 30 seconds after 1 min of dripping , the solution changed from light yellow to light gray before, and the precipitate was separated by centrifugation, washed several times with absolute ethanol and deionized water, and dried to obtain Ru-Cu with a mass fraction of 4% Ru doped 2 O wrapped Cu nanowires.

Embodiment 3

[0037] Preparation of Ru-Cu 2 O wrapped Cu nanowires

[0038] Add 120 mg of copper nanowires and 200 mL of deionized water to a round-bottomed flask, react in a water bath at 70°C for 6 hours, then cool to room temperature, filter, wash the filter cake with absolute ethanol and distilled water several times, and dry it in vacuo. Cu with a core-shell structure with an outer shell of a certain thickness 2 O is a nanowire with Cu as the core. Prepared Cu 2 Put 60 mg of nanowires with O as the shell and Cu as the core in a small beaker, slowly add 1.5 mL (mass fraction of 38.2%) ruthenium trichloride solution into the beaker, and let the mixture stand for 30 seconds after 1 min of dripping , the solution changed from the previous light yellow to light gray, and the precipitate was separated by centrifugation, washed several times with absolute ethanol and deionized water, and dried to obtain Ru-Cu with a mass fraction of 5% Ru doped 2 O wrapped Cu nanowires.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com