Low-angular-dependence blue cadmium-sulfide-structure color film and preparation method thereof

A cadmium sulfide, dependent technology, applied in the direction of cadmium sulfide, coating, etc., to achieve the effect of good sphericity, uniform seed particle size, and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

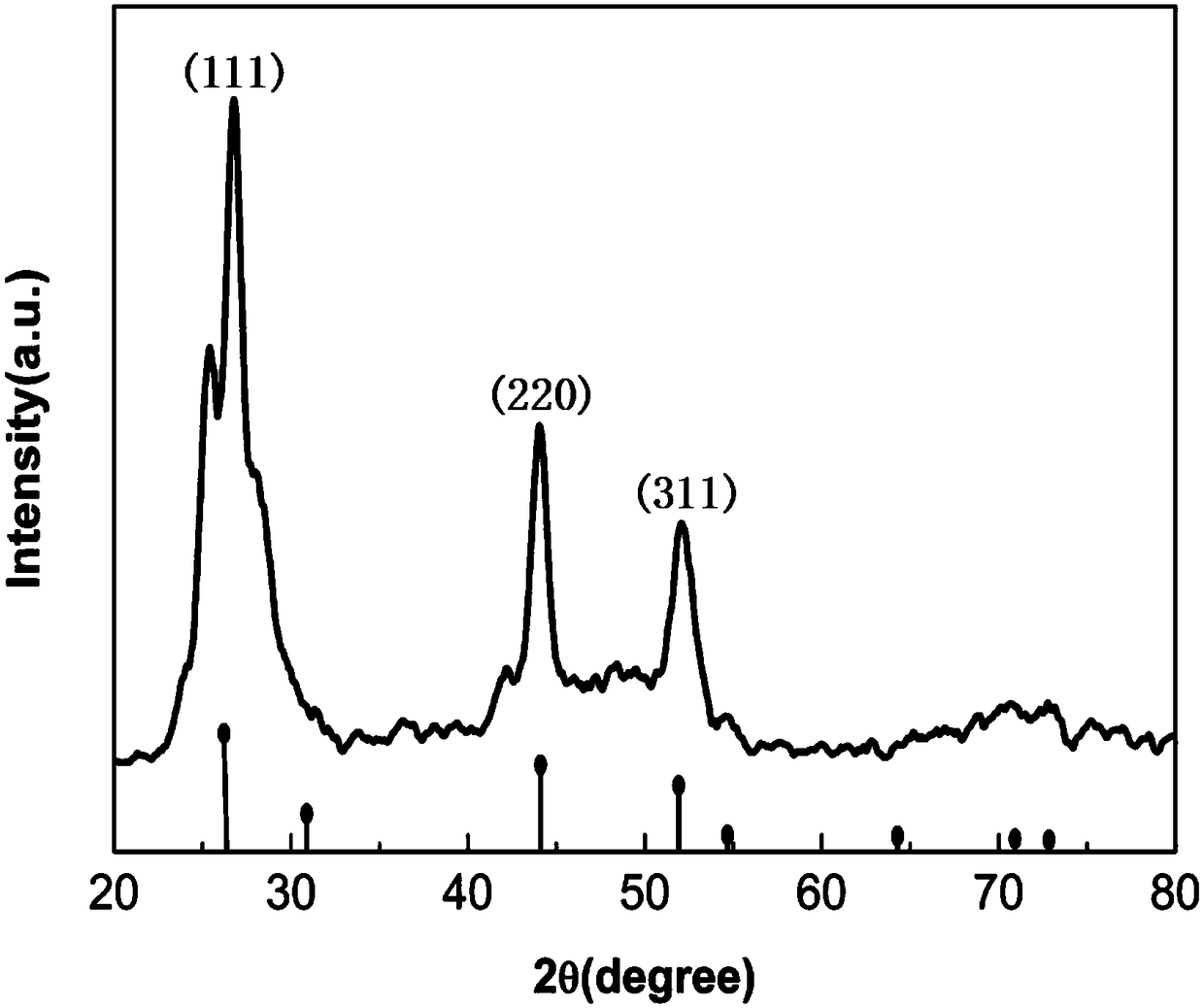

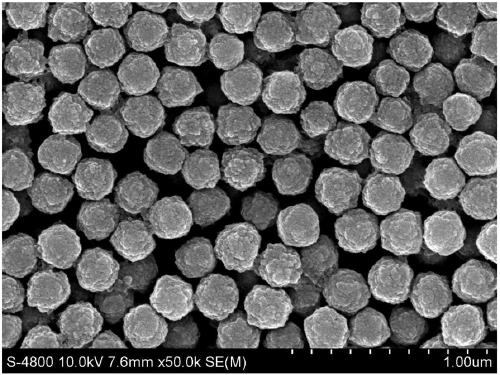

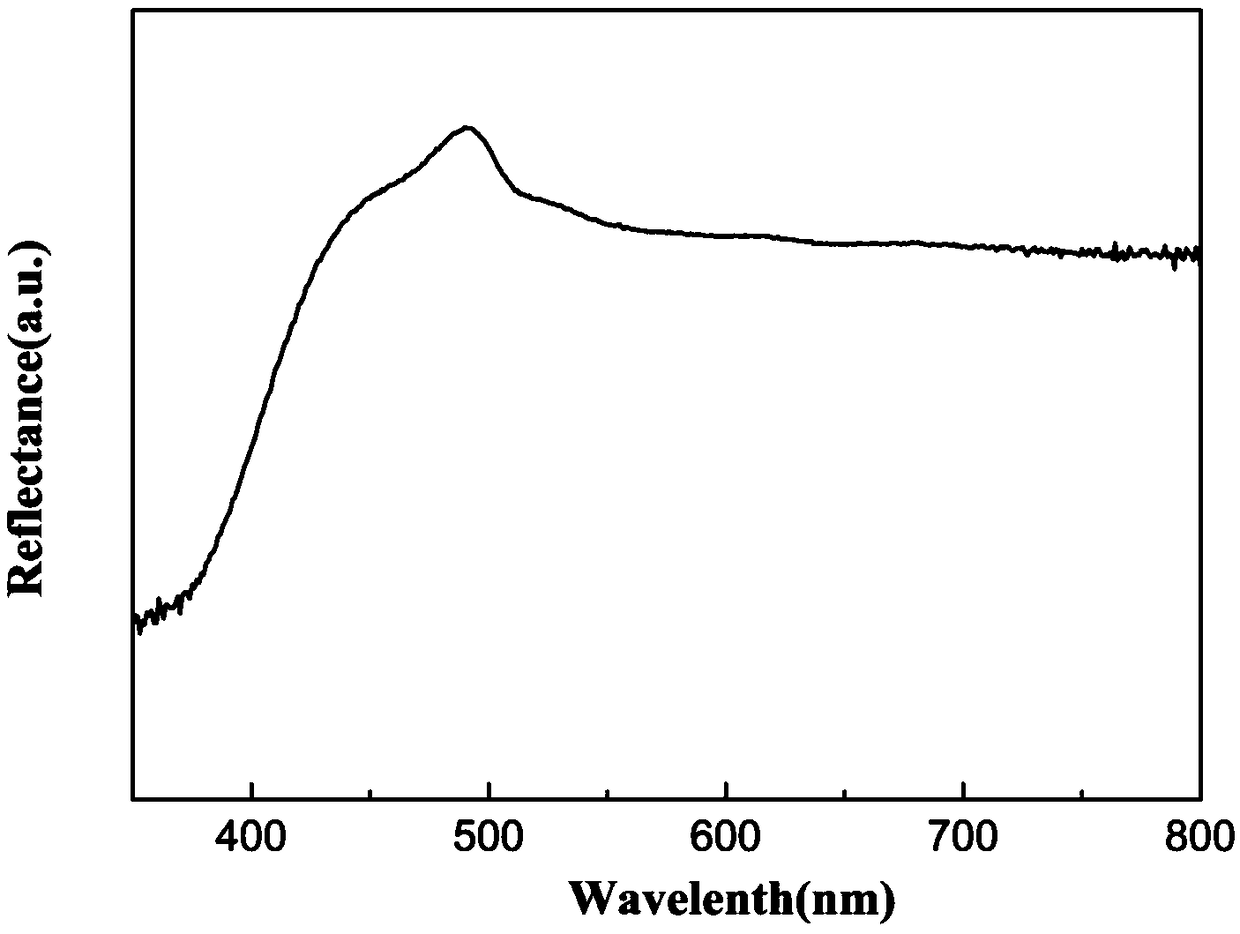

[0045] The preparation method of the low-angle-dependent blue cadmium sulfide structural color thin film of the present invention comprises the following steps:

[0046] 1) According to the ratio of (20-30) g: 80 mL, fully dissolve cadmium nitrate tetrahydrate in diethylene glycol, and let it stand to prepare the cadmium source; according to thiourea: diethylene glycol = (6-10) g: 80mL ratio, fully dissolve thiourea in diethylene glycol to obtain a uniform solution as a sulfur source;

[0047] 2) According to the ratio of (0.6-1.0) g: 60mL, dissolve polyvinylpyrrolidone in diethylene glycol, heat and magnetically stir to obtain a uniform mixed base solution; heat up, add sulfur source and cadmium source in step 1) successively , to react for a period of time; the ratio of the sulfur source to the mixed base solution is (180-240) μL: 60 mL, and the ratio of the cadmium source to the mixed base solution is (180-240) μ L: 60 mL.

[0048] 3) After the reaction in step 2), place i...

Embodiment 1

[0058] A method for preparing a low-angle-dependent blue cadmium sulfide structural color film, comprising the following steps:

[0059] 1) According to the ratio of 20g:80mL, stir cadmium nitrate tetrahydrate for 6h to fully dissolve in 80mL diethylene glycol, and let it stand for 1h to prepare the cadmium source; according to the ratio of thiourea:diethylene glycol=6g:80mL, the sulfur Urea was dissolved in 80mL of diethylene glycol, and magnetically stirred for 6 hours to mix well and obtain a uniform solution as a sulfur source.

[0060] 2) According to the ratio of 0.6g: 60mL, dissolve polyvinylpyrrolidone (PVP) in 60mL diethylene glycol, heat and magnetically stir for 2 hours, rotate at 500r / min, and heat at 60°C to obtain a uniform mixture Base solution; warm up to 190°C, first add 180 μL of the sulfur source in step 1), and then add 180 μL of the cadmium source in step 1).

[0061] 3) After step 2) was reacted for 6 minutes, it was quickly cooled in ice water at 10°C, ...

Embodiment 2

[0065] A method for preparing a low-angle-dependent blue cadmium sulfide structural color film, comprising the following steps:

[0066] 1) According to the ratio of 25g: 80mL, stir cadmium nitrate tetrahydrate for 7h and fully dissolve it in 80mL diethylene glycol, and let it stand for 1h to prepare the cadmium source; according to the ratio of thiourea:diethylene glycol=8g:80mL, the sulfur Urea was dissolved in 80mL of diethylene glycol, and magnetically stirred for 7 hours to mix well and obtain a uniform solution as a sulfur source.

[0067] 2) According to the ratio of 0.8g: 60mL, dissolve polyvinylpyrrolidone (PVP) in 60mL diethylene glycol, heat and magnetically stir for 1 hour, rotate at a speed of 500r / min, and heat at a temperature of 50°C to obtain a uniform mixture Base solution; warm up to 160°C, first add 200 μL of the sulfur source in step 1), and then add 200 μL of the cadmium source in step 1).

[0068] 3) After step 2) was reacted for 5 minutes, it was quick...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com