Sewage treatment control system

A control system and sewage treatment technology, which is applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, etc. It can solve fouling, troublesome disassembly and maintenance, light transmittance and Reduced photosensitivity and other issues, to achieve good control effect, good control effect, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Such as figure 1 A treatment device for the treatment of printing and dyeing wastewater is shown, which uses a new detection method to detect whether the printing and dyeing wastewater is turbid, and uses the light transmittance index of the treated supernatant as a control point, so the present invention The existing process is improved, and the control system is well structured on the basis of the new process.

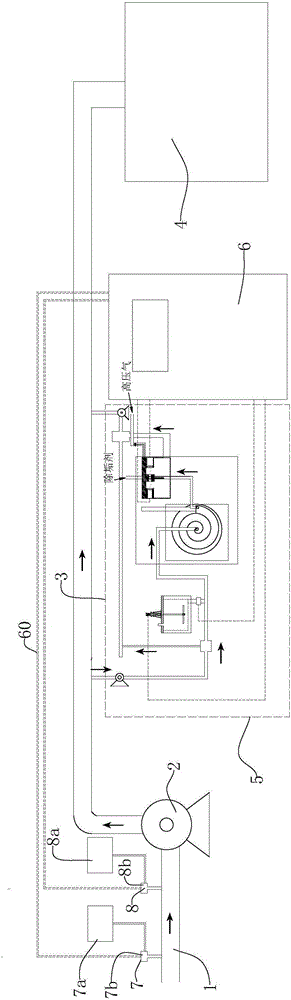

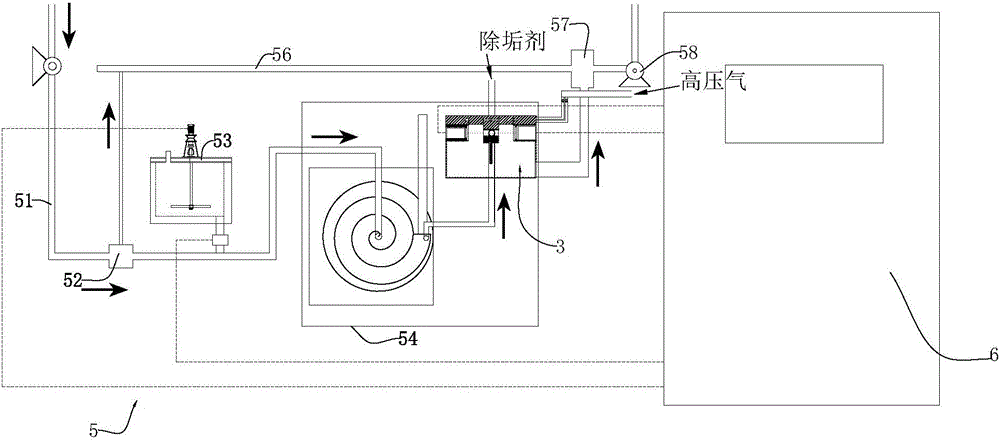

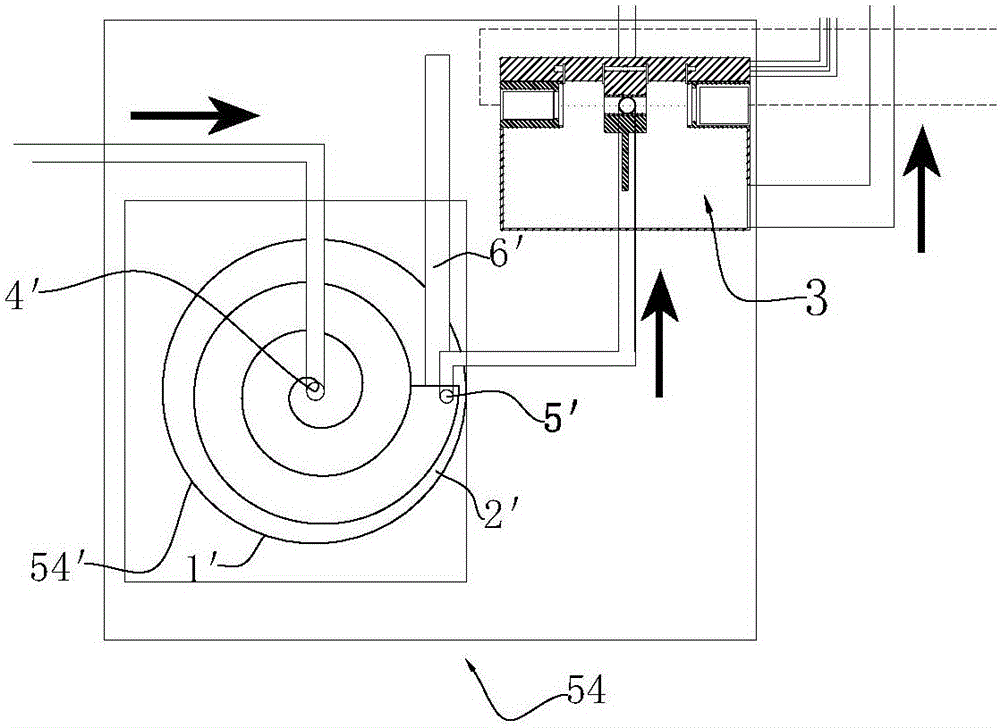

[0051] see Figure 1-15 As shown, the sewage treatment control system includes a water inlet pipe section 1, a decolorizing agent adding device 7, a coagulation aid adding device 8, a sewage pump 2, a water delivery pipeline, a sampling detection device 5 for detecting wastewater treatment indicators, a control box 6 and Sedimentation tank 4. The water inlet pipe section 1 is connected to the water delivery pipe through the sewage pump 2, and the end of the water delivery pipe is connected to the sedimentation tank 4. The arrow in the figure points to the fl...

Embodiment 2

[0079] The difference between this embodiment and embodiment 1 is that this embodiment adopts another settling device, such as Figure 16 As shown, the settling device consists of a rectangular box 10' and a plurality of baffles 20' interlaced and fixed on the inner walls of both sides of the rectangular box 10'. One end of the rectangular box 10' is provided with a water inlet pipe 40'. The rectangular box The bottom of the other end of the 10' is provided with a sedimentation outlet 60', and a supernatant outlet 50' is opened on the top wall near the other end of the rectangular box 10', and the supernatant outlet 50' is connected to the The water inlet pipe 330 in the light transmittance detector 3 of the light transmittance of the printing and dyeing wastewater supernatant. The rest are repeated in Example 1, and will not be described in detail.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com