Adaptive smart synchronous high-speed switching device

A high-speed switching and self-adaptive technology, applied in high-voltage/high-current switches, electric switches, high-voltage air circuit breakers, etc., can solve the problems of large dispersion of three-phase action time, economic loss of enterprises, and difficulties in switching off and on, achieving Guarantee the effect of anti-interference ability and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

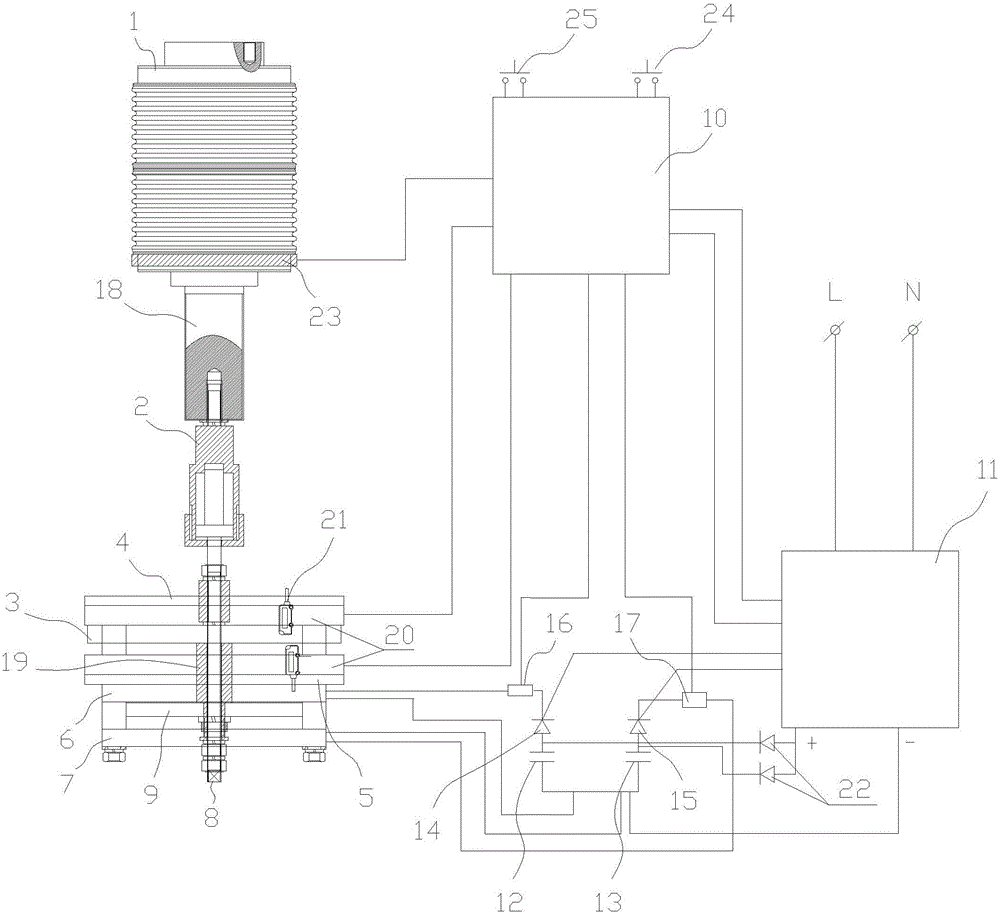

[0021] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

[0022] Such as figure 1 As shown, an adaptive intelligent synchronous high-speed switching device includes a vacuum interrupter 1, a buffer 2, a suction plate 3, an upper yoke 4, a lower yoke 5, an opening coil 6, a closing coil 7, and a center shaft Rod 8, eddy current disk 9, control template 10, fast charging switching power supply module 11, opening capacitor bank 12, closing capacitor bank 13, opening thyristor 14, closing thyristor 15, opening adaptive variable impedance Device 16, closing adaptive variable impedance device 17;

[0023] The moving contact rod 18 on the vacuum interrupter 1 is connected with the buffer 2, and the buffer 2 is connected with the central shaft rod 8, and the central shaft rod 8 is respectively connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com