Generator, preparation method therefor, and generator set

A technology for generators and power generation units, applied in the direction of friction generators, etc., can solve the problems of weak charging ability and difficult to meet the energy supply demand of electronic devices, and achieve the effect of improving output performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

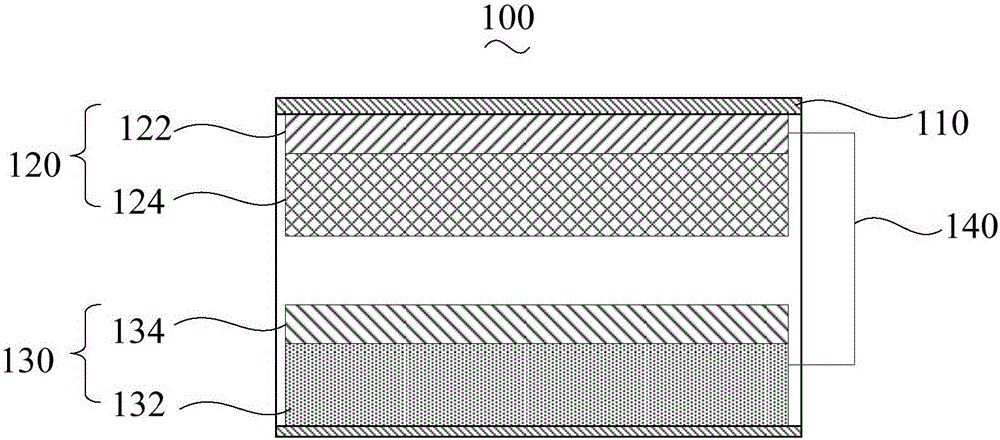

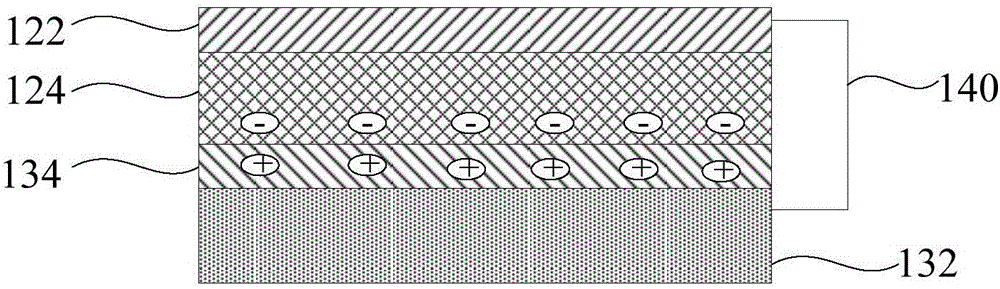

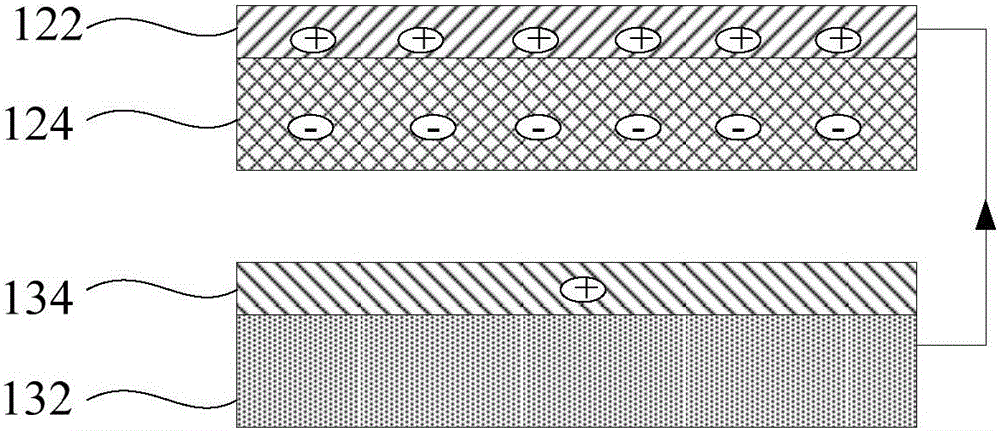

[0050] like Figure 4 Shown, the preparation method of the generator of an embodiment, comprises the following steps:

[0051] Step S210: forming an electret layer on the electrode layer, and negatively charging the electret layer to obtain a power generation unit.

[0052] Wherein, the material of the electrode layer is selected from one of nickel, aluminum, gold, silver, copper and indium tin oxide.

[0053] Wherein, the material of the electret layer is selected from amorphous fluororesin, polydimethylsiloxane, polytetrafluoroethylene, fluorinated ethylene propylene copolymer, polycarbonate, polyperfluoroethylene propylene, polypropylene, polyethylene , silicon dioxide and silicon nitride on silicon.

[0054] Among them, the method for negatively charging the electret layer is the three-electrode discharge method, that is, the voltage between the needle tip and the ground of the high-voltage charging and discharging device is 6000V, and the voltage between the gate and th...

Embodiment 1

[0080] The preparation process of the generator of the present embodiment is as follows:

[0081] (1) Coating amorphous fluororesin on the electrode layer with a thickness of 20 microns, curing at 180°C to form an electret layer, using a high-voltage charging and discharging device to negatively charge the electret layer, and during the negative charging process, The voltage between the needle tip and the ground is 6000V, the voltage between the grid and the ground is 2000V, and the charging time is 10 minutes to obtain a power generation unit. Wherein, the material of the electrode layer is aluminum.

[0082] (2) Forming a friction layer with a thickness of 200 microns on one surface of a support film with a thickness of 50 microns by magnetron sputtering to obtain a friction unit. Wherein, the material of the supporting film is polyimide; the material of the friction layer is aluminum.

[0083] (3) Provide a support, the support is a cylindrical shell with openings at both...

Embodiment 2

[0085] The preparation method of the generator of this embodiment is similar to the preparation method of the generator of Example 1, the only difference is that: the material of the electrode layer is nickel, the material of the electret layer is polydimethylsiloxane, and the material of the support film The material is polyvinyl chloride, and the material of the friction layer is nickel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com