Preparation method of selenium powder

A technology of selenium powder and selenium block, which is applied in the direction of element selenium/tellurium, can solve the problems of large friction loss between the grinding body and the body, large energy consumption, low work efficiency, etc., and achieves short time consumption, improved production efficiency, and low pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

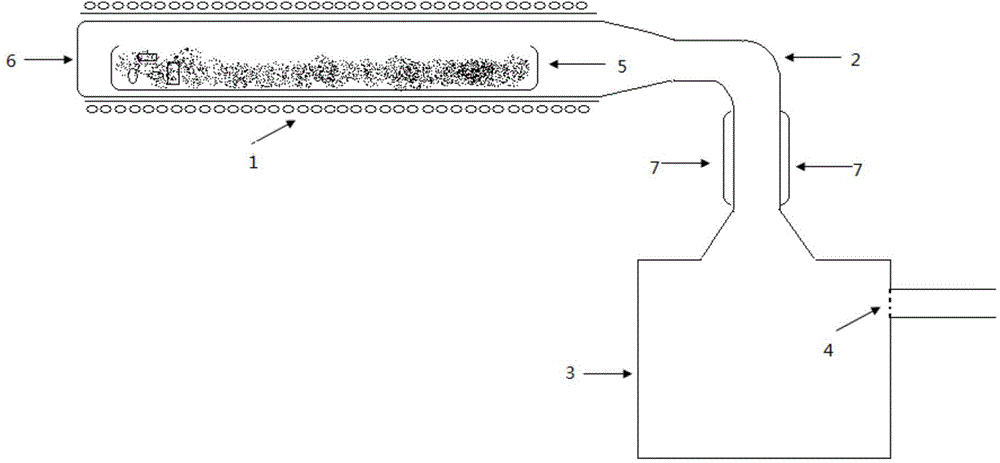

Image

Examples

preparation example Construction

[0015] The invention provides a kind of preparation method of selenium powder, comprises the following steps:

[0016] Put selenium blocks or selenium particles into the quartz tube, connect the reaction device, turn on the condensing equipment, set the temperature required for condensation, set the heating temperature, turn on the heating, after the selenium blocks are all vaporized, turn off the heating, and after cooling Collect the selenium powder from the collection bottle.

[0017] In the present invention, selenium particles or selenium blocks are heated, evaporated and cooled, and after the selenium blocks or selenium particles are evaporated and condensed, the selenium powder can be obtained. The method provided by the invention requires simple equipment, simple process steps and short time consumption, thereby improving the production efficiency of the selenium powder. Moreover, the selenium powder obtained by the preparation method provided by the invention has uni...

Embodiment 1

[0022] Put 10kg of selenium particles into the quartz tube, connect the device; turn on the condensing device, set the condensing temperature to 5°C, turn on the heating, heat at 10°C per minute, heat to 650°C for 2.5h, and then at 4°C per minute, Heat to 720°C. After all the selenium blocks are vaporized, turn off the heating, and obtain selenium powder from the collection bottle after cooling.

Embodiment 2

[0024] Put 5kg of selenium particles into the quartz tube, connect the device; turn on the condensing device, set the condensing temperature to 10°C, turn on the heating, heat at 8°C per minute, heat to 600°C for 2.5h, and then at 2°C per minute, Heat to 690°C. After all the selenium blocks are vaporized, turn off the heating, and obtain selenium powder from the collection bottle after cooling.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com