Quartz cladding large-power-transmission dispersion optical fiber and manufacturing method thereof

A technology of silica-clad and dispersed optical fiber, which is applied in clad optical fiber, multi-layer core/clad optical fiber, manufacturing tools, etc. It can solve problems such as poor heat resistance, low transmittance of polymer materials, and color change. Achieve the effect of improving stability and reliability, solving the problem of color transformation, and reducing the change of scattering loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

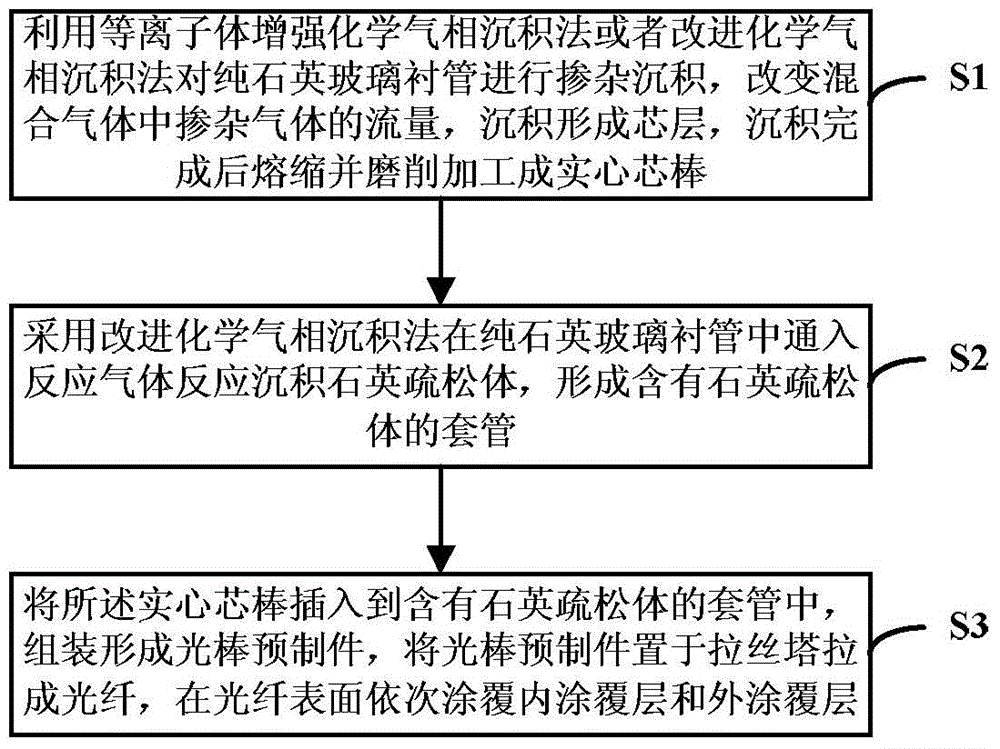

Method used

Image

Examples

Embodiment Construction

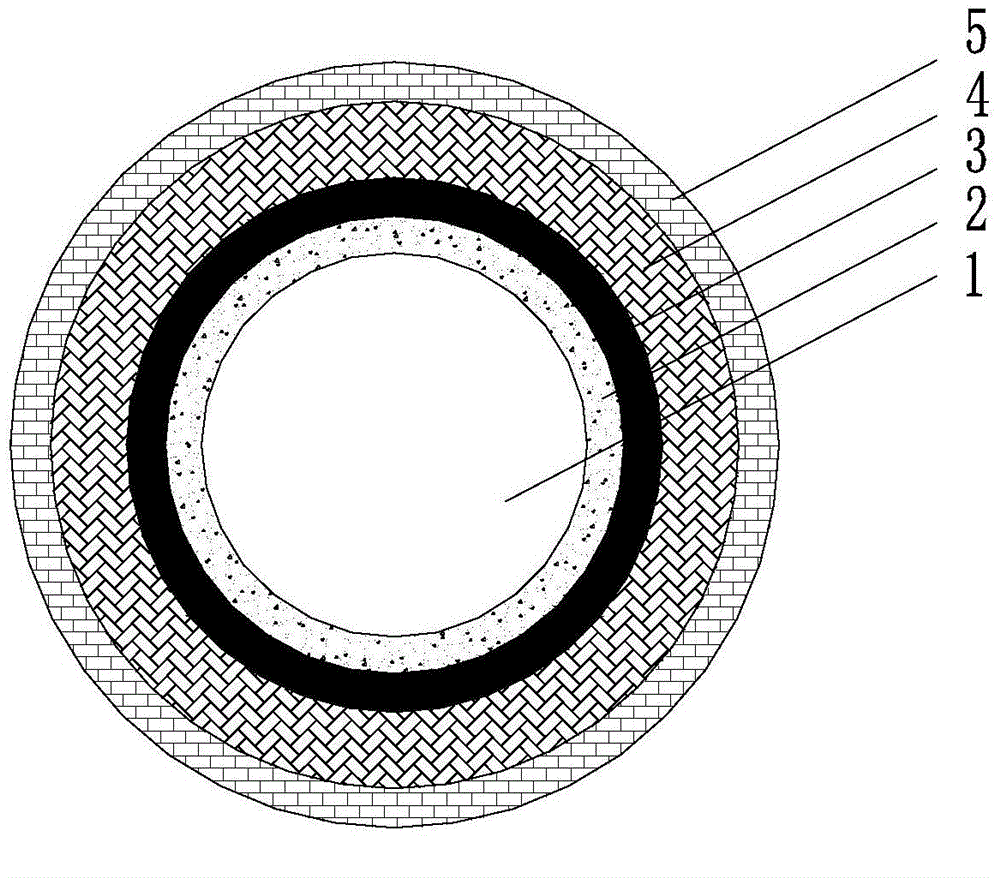

[0025] In order to facilitate the understanding of the present invention, at first the professional terms involved in the present invention are collectively defined as follows:

[0026] Quartz Liner: A tubular substrate tube whose inner wall bears a glassy oxide deposit of plasma-enhanced chemical vapor deposition (PCVD) chemical reaction.

[0027] Sleeve: A quartz glass tube that meets certain geometrical indicators and doping requirements.

[0028] Core layer: It is located in the central part of the cross-section of the optical fiber and is the main light-guiding area of the optical fiber.

[0029] Light-scattering first silica cladding: the ring-shaped region next to the core in the cross-section of the fiber.

[0030] Second Silica Cladding: The annular region in the fiber cross-section immediately adjacent to the silica cladding where light is scattered.

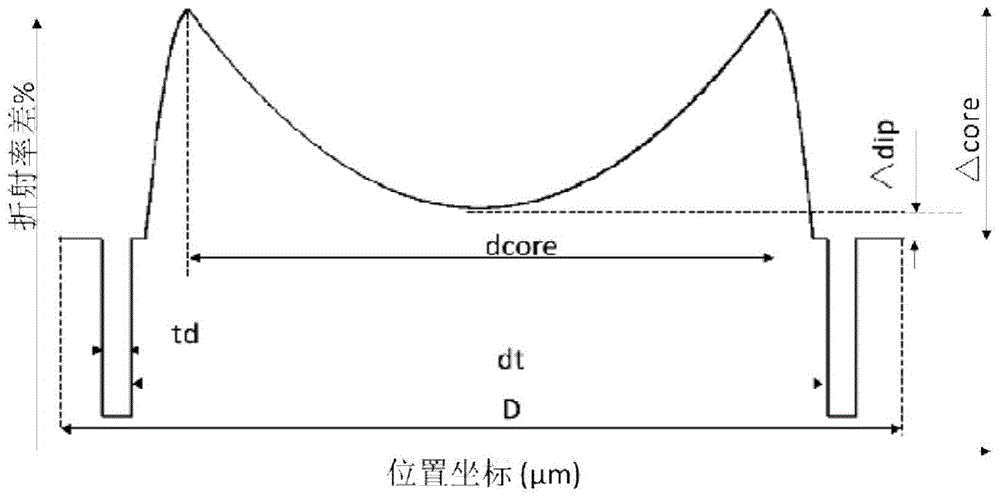

[0031] Relative refractive index difference: Δ % = [ ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com