Dried alum calcining device and method

A technology of forging and equipment, which is applied in the field of dry alum forging equipment and forging, which can solve the problems of drooping or perforation of the bottom of the pot, affecting the health of personnel, and falling off of iron filings at the bottom of the pot, so as to improve the production environment and increase the efficiency of forging , easy to clear the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

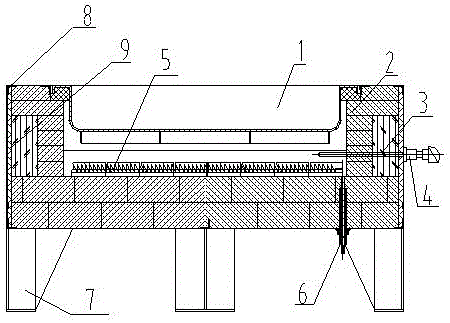

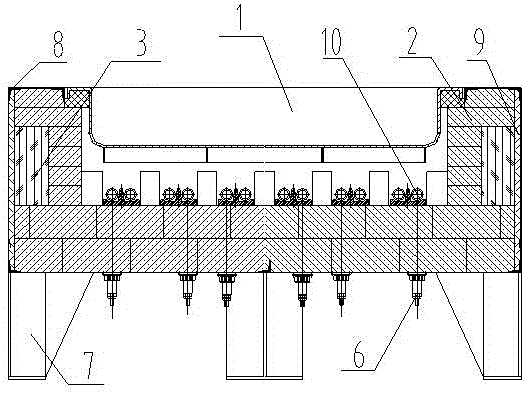

[0033] A kind of dry alum forging equipment, see figure 1 and figure 2 , including a shell 9, a processing chamber 1, a heating unit, a heat preservation unit and a temperature control unit;

[0034] The casing 9 and the processing chamber 1 of the present embodiment are all made of stainless steel, and the processing chamber 1 is a cylindrical shape with a flat bottom, a diameter of φ1200mm, and a height of 150mm;

[0035] The heating unit is an E-type thermocouple 4 and three 0Cr25Al5 heating wires 5;

[0036] The thermal insulation unit includes high alumina wire bricks 10, lightweight refractory bricks 2 and aluminum silicate thermal insulation blankets 3, wherein the lightweight refractory bricks 2 are 750 pieces in total, and the lightweight refractory bricks 2 are laid on the periphery of the treatment chamber 1 and At the bottom, lightweight refractory bricks 2 are laid on the outer periphery of E-type thermocouple 4 and the bottom of 0Cr25Al5 heating wire 5 at the ...

Embodiment 2

[0042] A dry alum forging method, the steps are: take 13kg raw material alum, stand-by; open the forging equipment of embodiment 1, set the internal temperature of the treatment chamber 1 to 200°C, and set the temperature at the bottom of the treatment chamber 1 to 350°C; Put 13kg of alum into the treatment chamber 1, and start calcining timing after the temperature display reaches the target temperature; after calcining for 1 hour, it becomes white, loose, honeycomb, light in weight, and fragile when twisted by hand. alum, weighing 6.5kg; the calcining efficiency has been improved by more than 2 times, and the finished product obtained has uniform color and stable quality.

Embodiment 3

[0044] A dry alum forging method, the steps are: take 13kg raw material alum, stand-by; open the forging equipment of embodiment 1, set the internal temperature of the treatment chamber 1 to 150°C, and set the temperature at the bottom of the treatment chamber 1 to 500°C; Put 13kg of alum into the treatment chamber 1, and start calcining timing after the temperature display reaches the target temperature; after calcining for 1.2 hours, it becomes white, loose, honeycomb, light in weight, and fragile when twisted by hand. Close the equipment and collect the finished product. alum, weighing 6.5kg; the calcining efficiency has been improved by more than 2 times, and the finished product obtained has uniform color and stable quality.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com