Wound irrigation and negative pressure drainage device and usage method thereof

A negative pressure drainage and wound surface technology, which is applied in wound drainage devices, enema devices/irrigators, suction devices, etc., can solve the problems of high wound surface secondary pollution rate, complex device structure, short battery life, etc., and achieve novel device structure. , high safety and long battery life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

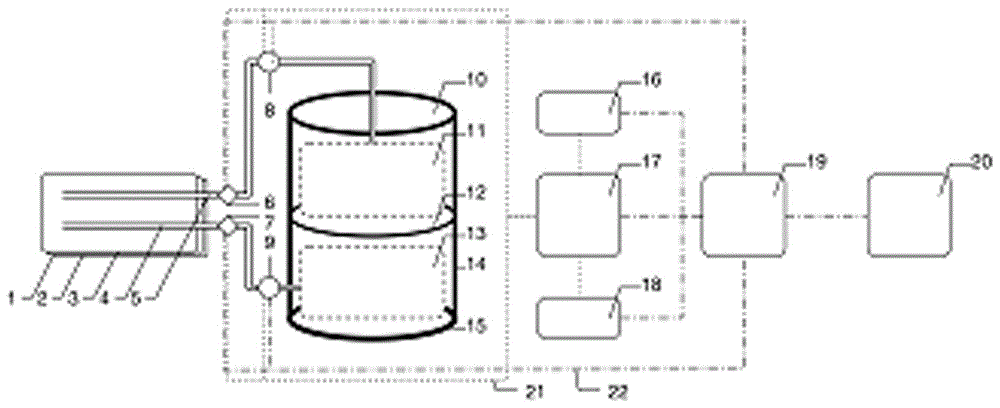

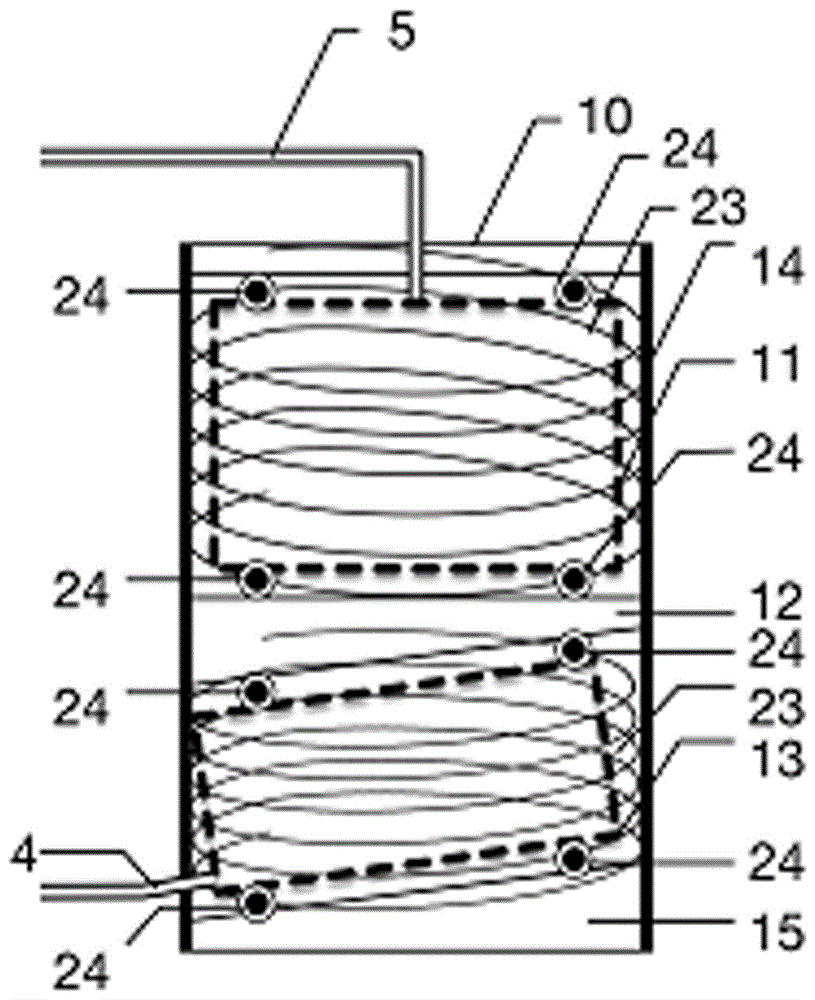

[0040]The specific operation process of the wound surface intermittent flushing-negative pressure negative pressure mode of this device is as follows: the operator sets the amount of wound flushing to the central processing unit 17 through the keyboard 18, the retention time of wound liquid, the duration of negative pressure on the wound surface and the total operation time of the device. The state is displayed on the display 16, the central processing unit 17 starts the timing of the total running time of the device and the timing of the wound surface perfusion, the device starts the first liquid injection-closed drainage cycle, the valve 9 of the infusion pipeline is opened, the valve 8 of the negative pressure pipeline is closed, and the liquid storage bag 13 The inner liquid enters the foam dressing 2 through the infusion pipeline 4 under the action of the spring 23 and the partition 12, and the flow sensor 7 records the amount of liquid flowing through the infusion pipeline...

Embodiment 2

[0042] The specific operation process of the wound intermittent negative pressure mode of the device is as follows: the operator sets the duration of wound negative pressure, the intermittent time of wound negative pressure and the total operating time of the device to the central processing unit 17 through the keyboard 18, and the operating status of the device is displayed on the display 16. The liquid storage bag 13 is in a compressed state under the action of the spring 23, and the volume of the negative pressure bag 11 is maximized. The central processing unit 17 starts counting the total running time of the device and the duration of negative pressure on the wound surface. The valve 9 of the infusion pipeline is closed, and the valve of the negative pressure pipeline 8 open, the liquid in the foam dressing 1 enters the negative pressure bag 11 under the action of negative pressure, the pressure receptor 6 detects the wound pressure and transmits the signal to the central p...

Embodiment 3

[0044] The specific operation process of the negative pressure mode of continuous wound closure of the device is as follows: the operator sets the total operating time of the device through the keyboard 18, the operating status of the device and the pressure value of the wound surface are displayed on the display 16, and the liquid in the liquid storage bag 13 flows between the spring 23 and the separator Under the action of 12, it is in a compressed state, the volume of the negative pressure bag 11 is maximized, the central processing unit 17 starts counting the total running time of the device, the valve 9 of the infusion pipeline is closed, the valve 8 of the negative pressure pipeline is opened, and the liquid in the foam dressing 2 is under the action of negative pressure Entering the negative pressure bag 11, the baroreceptor 6 detects the wound surface pressure and transmits the signal to the central processing unit 17 in real time. When the total running time of the dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com