High-power continuous fiber laser-based hot-drawing, molding and welding apparatus for spiral fin coil

A fiber laser and spiral finned tube technology, which is applied in the production field of spiral finned tubes, can solve the problems of low bonding strength, low thermal conversion efficiency, low precision of forming molds, etc. The effect of easy stretch forming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

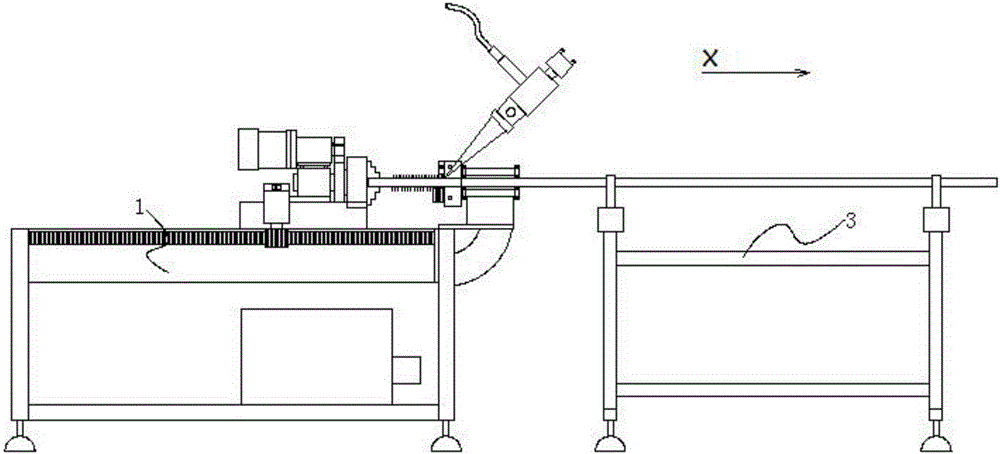

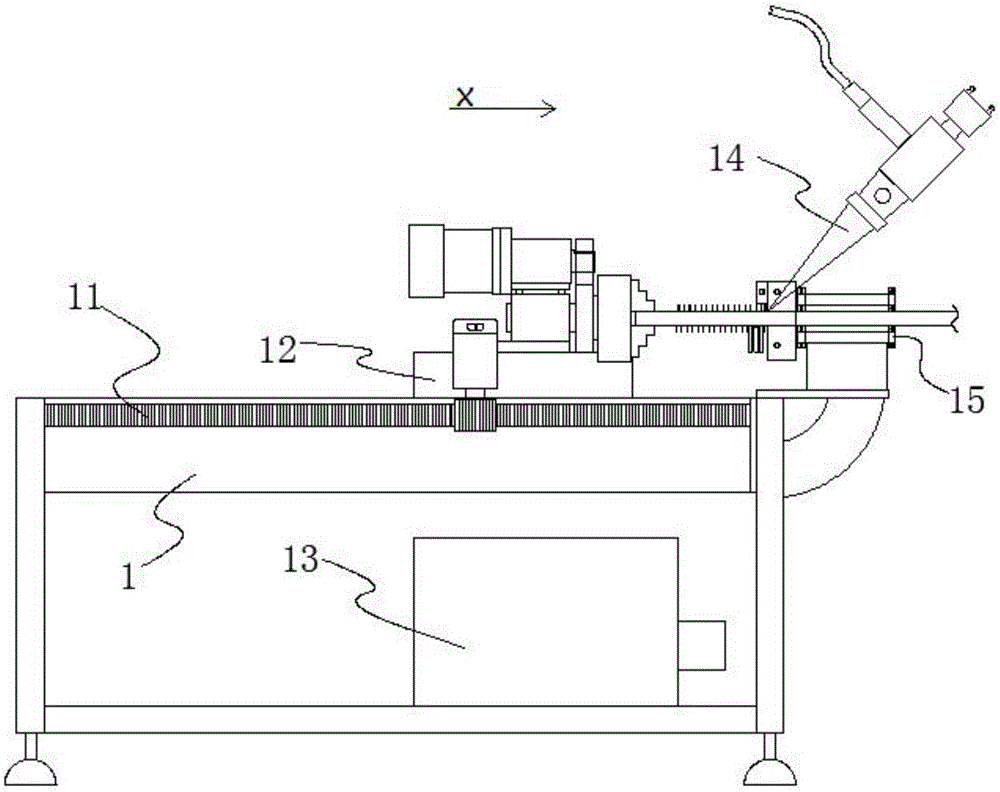

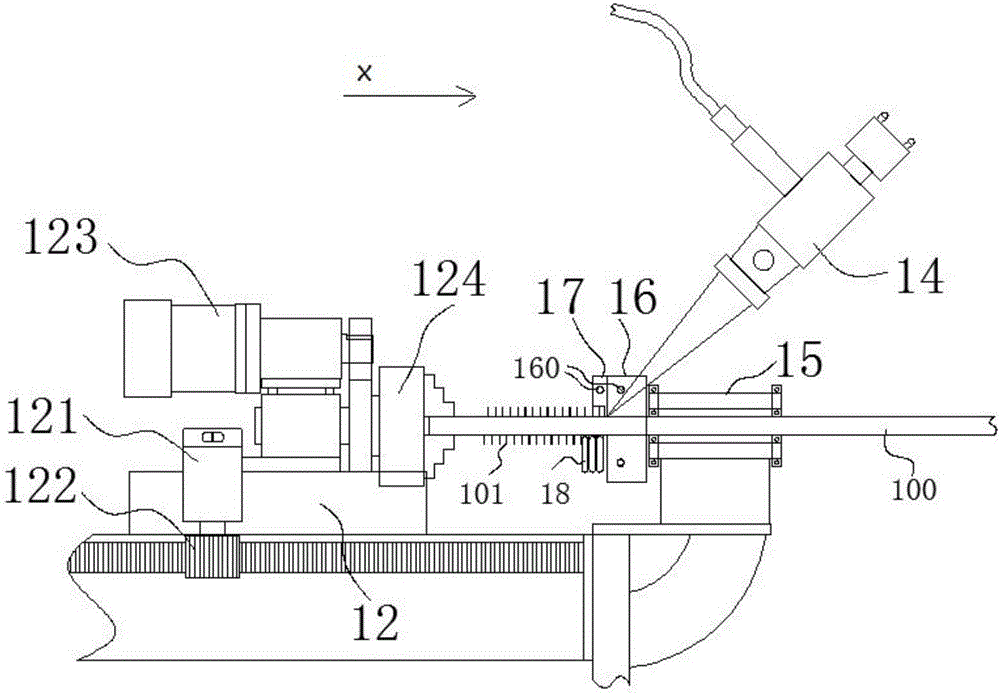

[0032] see Figure 1 to Figure 8 , an embodiment of a high-power continuous fiber laser spiral finned tube heat-drawing welding equipment, including a main frame 1, a pair of linear racks 11 are horizontally arranged on the main frame 1 along the X-axis direction, and the main shaft seat 12 is movably arranged on the main frame 1 and is located between a pair of linear racks 11, and a pair of traveling motors 121 are arranged vertically on the main shaft base 12, and a pair of traveling motors 121 are transmission-connected to the pair of linear racks. 11 engaged with a pair of gears 122, thereby driving the main shaft seat 12 to walk on the main frame 1, and then dragging the steel pipe 100 to move in the X-axis direction; the chuck rotating motor 123 is fixed on the main shaft seat 12,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com