Decorative sheet for coating

A decorative board and cladding technology, which is applied to household components, wood processing appliances, etc., can solve the problems of costing a lot of manual polishing and spraying paint, causing great harm to human body, and not being able to coat special-shaped substrates, so as to improve the decoration factory environment , Improving the efficiency of finished products and improving the convenience of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

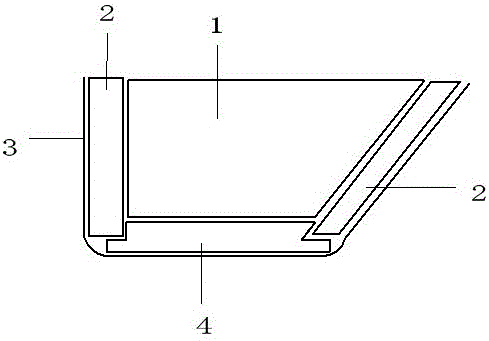

[0028] Such as figure 2 As shown, a decorative panel for cladding includes a decorative surface and a plate, the plate is located on the decorative surface, and two cladding grooves are provided on the plate, one side of the cladding groove is stepped, and the cladding concave The groove divides the plate into a bent plate and a bearing plate. One side of the bearing plate is stepped. The bent plate includes a first surface and a second surface. The first surface and the second surface form a top angle, and the bearing plate is sequentially Including the first horizontal step surface, the first vertical step surface, the second horizontal step surface and the second vertical step surface, the first vertical step surface and the second horizontal step surface form an included angle, and the angle of the top angle is the same as the angle of the included angle , the angles are 120 degrees and 90 degrees respectively, the second vertical step surface is connected to the decorati...

Embodiment 2

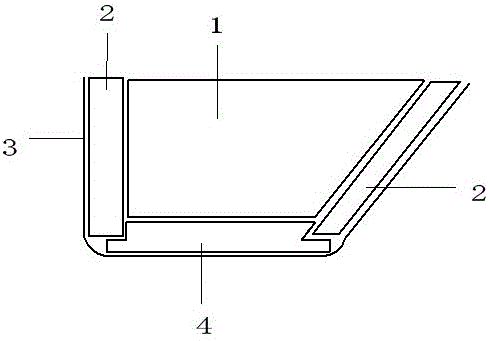

[0030] Such as Figure 4 As shown, a decorative panel for cladding includes a decorative surface and a plate, the plate is located on the decorative surface, and two cladding grooves are provided on the plate, one side of the cladding groove is stepped, and the cladding concave The groove divides the plate into a bent plate and a bearing plate. One side of the bearing plate is stepped. The bent plate includes a first surface and a second surface. The first surface and the second surface form a top angle, and the bearing plate is sequentially Including the first horizontal step surface, the first vertical step surface, the second horizontal step surface and the second vertical step surface, the first vertical step surface and the second horizontal step surface form an included angle, and the angle of the top angle is the same as the angle of the included angle , the angles are 60 degrees and 90 degrees respectively, the second vertical step surface is connected to the decoratio...

Embodiment 3

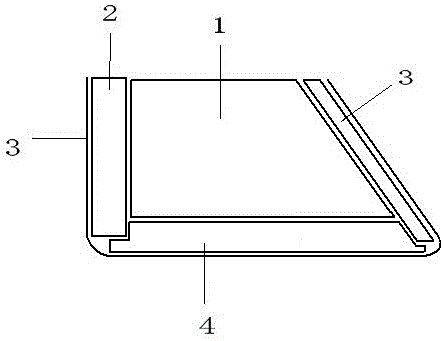

[0032] A decorative panel for cladding, including a decorative surface and a plate, the plate is located on the decorative surface, and the plate is provided with 3 cladding grooves, one side of the cladding groove is stepped, and the cladding groove connects the plate Divided into a bent plate and a bearing plate, one side of the bearing plate is stepped, the bent plate includes the first surface and the second surface, the first surface and the second surface form a top angle, and the bearing plate includes the first The horizontal stepped surface, the first vertical stepped surface, the second horizontal stepped surface and the second vertical stepped surface, the first vertical stepped surface and the second horizontal stepped surface form an included angle, the angle of the top angle and the angle of the included angle are the same, and the angles are respectively 120 degrees and 90 degrees, the second vertical stepped surface is connected to the decorative surface, the wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com