Automatic transportation system, automatic test system and automatic detection method

A technology for automated testing and transportation systems, applied in transportation and packaging, conveyors, measuring devices, etc., can solve the problems of long testing time and many equipment, and achieve the effect of enhancing objectivity, reducing labor intensity, and simplifying the testing process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

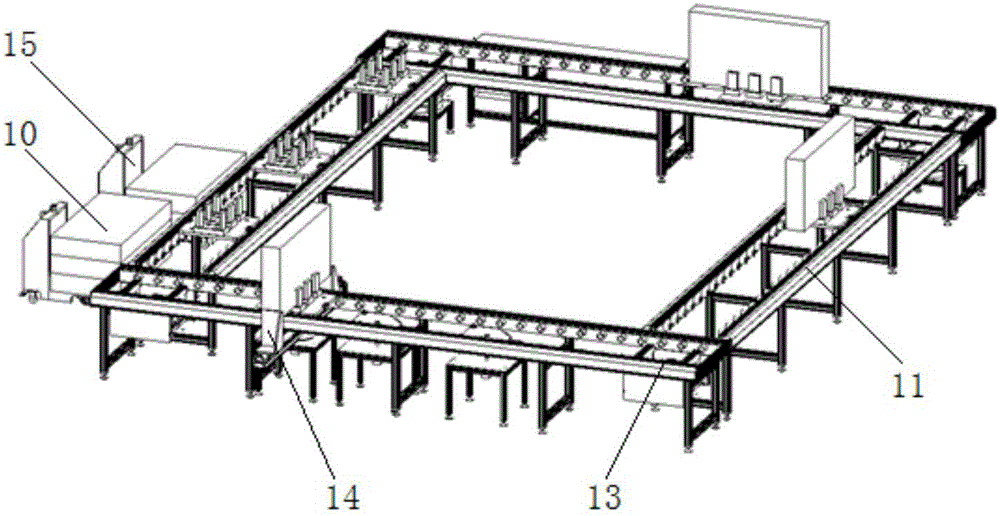

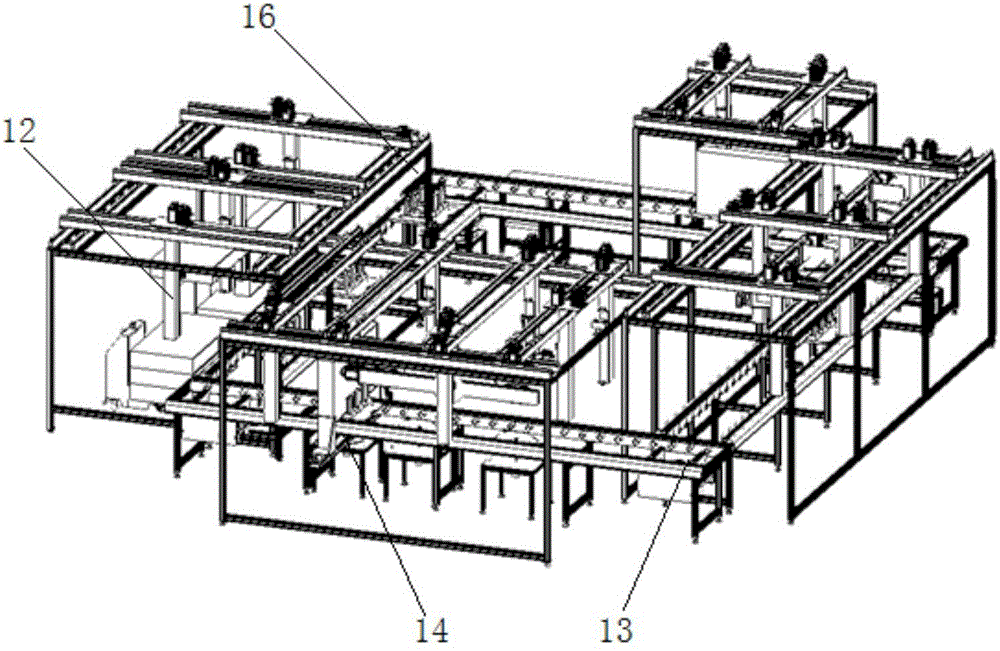

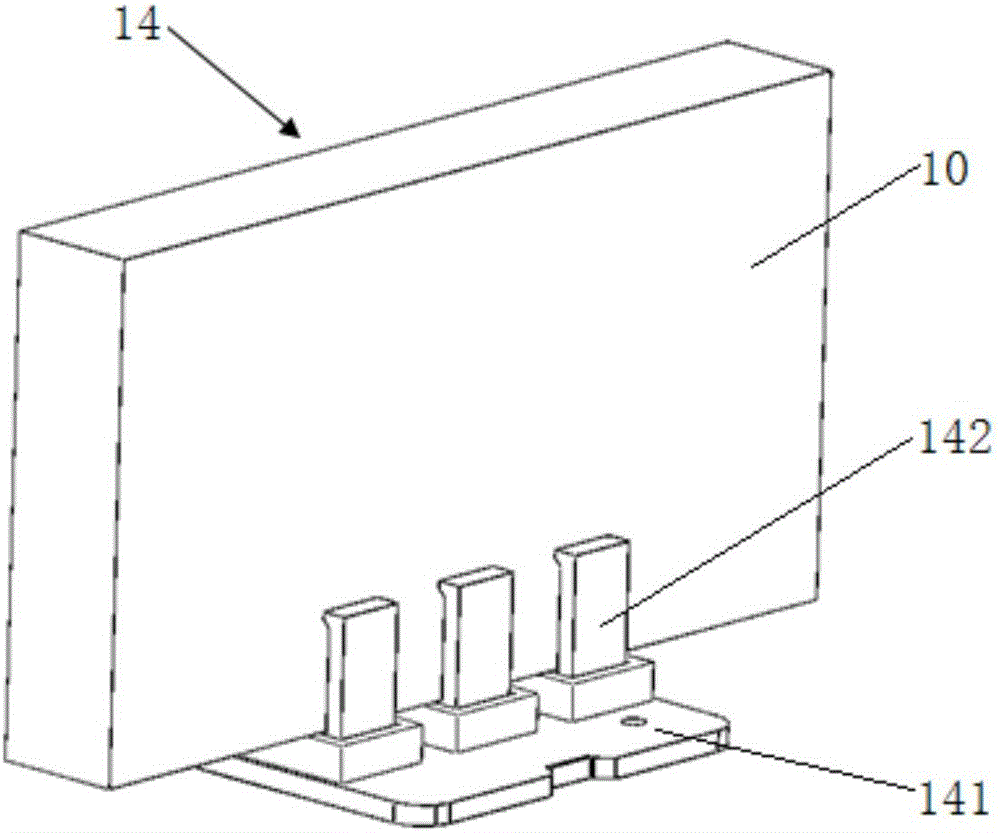

[0022] Please refer to figure 1 and figure 2 As shown, this embodiment provides an automatic transportation system for automatic transportation of workpieces 10, including an accumulation type roller conveyor line 11 for transporting workpieces 10, and a loading and unloading machine arranged above the accumulation type roller conveyor line 11 Device 12, a rotary lifting transplanter 13 arranged at the corner of the accumulation type roller conveyor line 11, a workpiece fixing transport device 14 arranged on the accumulation type roller conveyor line 11, wherein the loading and unloading mechanical device 12 will automatically carry The workpiece 10 on the car 15 is placed on the loading position of the accumulation type roller conveying line 11 by the manipulator, and the workpiece fixing and transporting device 14 fixes the workpiece on the tooling floor along the accumulation type roller conveying line. 11 for conveying, through the rotary lifting transplanter 13 to compl...

Embodiment 2

[0029] Such as figure 2 As shown, this embodiment provides an automated testing system for automatically detecting the performance of workpieces, including the automated transportation system described in Embodiment 1, a control system connected to the automated transportation system, and a control system connected to the control system. Automated testing equipment, wherein the automated testing equipment is set on the workpiece automatic transportation system.

[0030] The automated testing system described in this embodiment is used to automatically detect the performance of workpieces, including the automated transportation system described in Embodiment 1, the control system connected to the automated transportation system, and the automated testing equipment connected to the control system , the test of the workpiece 10 is controlled and set through the control system, which is conducive to improving the automation of the test system, so that the test process does not re...

Embodiment 3

[0039] This embodiment provides an automatic detection method, which uses the automatic test system described in Embodiment 2 to detect the performance of the workpiece, and the steps are as follows: Step S1: automatically transport the workpiece to the loading station; Perform various detection tests on the workpiece; Step S3: Upload the various data after the detection to the information platform to complete the test on the workpiece.

[0040] In the automatic detection method described in this embodiment, in the step S1, the workpiece is automatically transported to the loading station to avoid manual operation, which is beneficial to the automatic detection of the workpiece; Various detection tests are carried out on the workpiece, which is beneficial to reduce the labor intensity of the inspectors and improve the test efficiency; in the step S3, upload the various data after the detection to the information platform, and then analyze the data to complete The testing of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com