Preparation process of polyaluminum chloride

A polyaluminum chloride and preparation technology, applied in the direction of aluminum chloride, aluminum halide, etc., can solve the problems of the final purity of polyaluminum chloride, environmental pollution, waste of hydrochloric acid, etc., to save steps, improve efficiency, reduce The effect of the possibility of decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

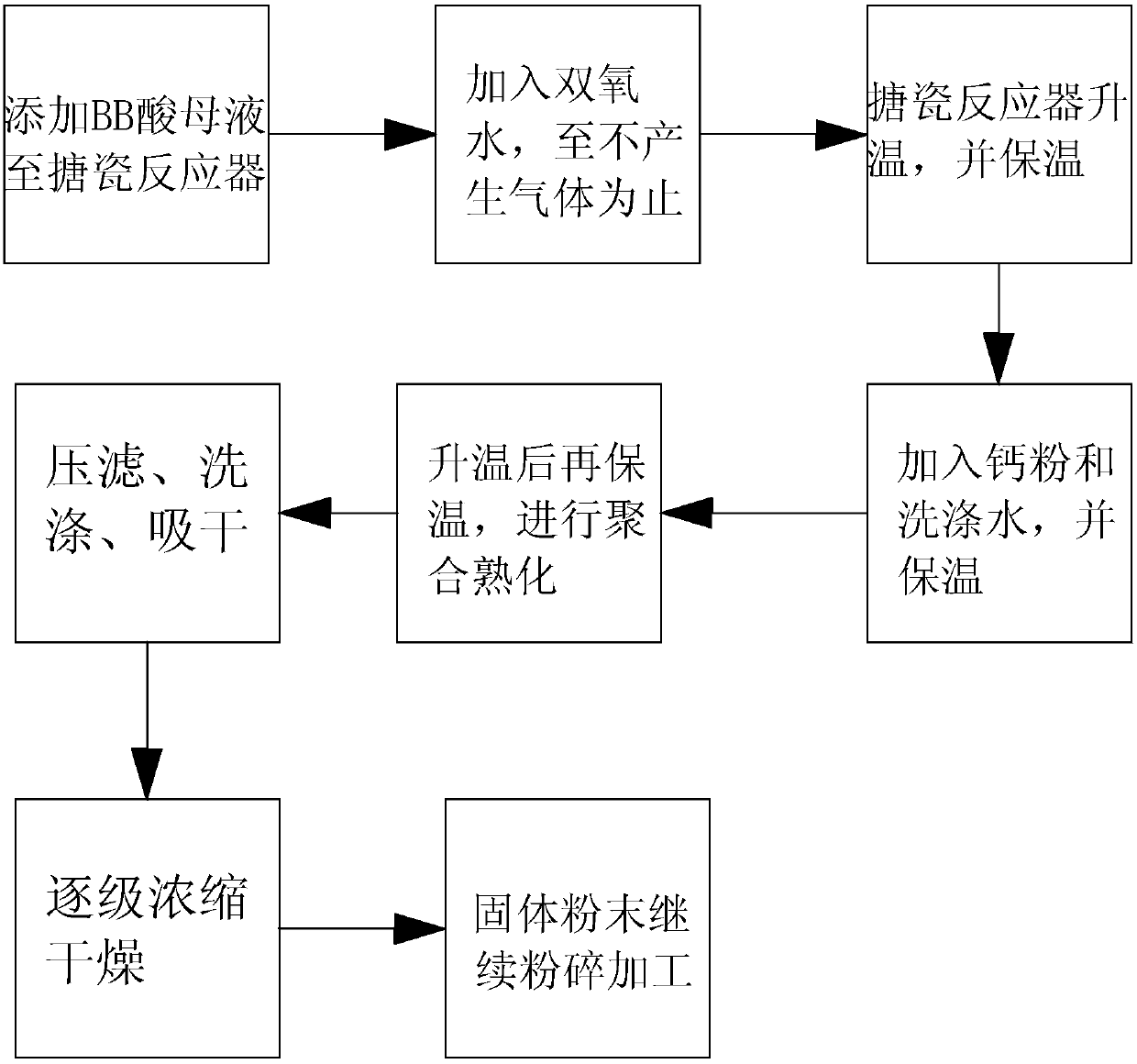

Method used

Image

Examples

Embodiment 1

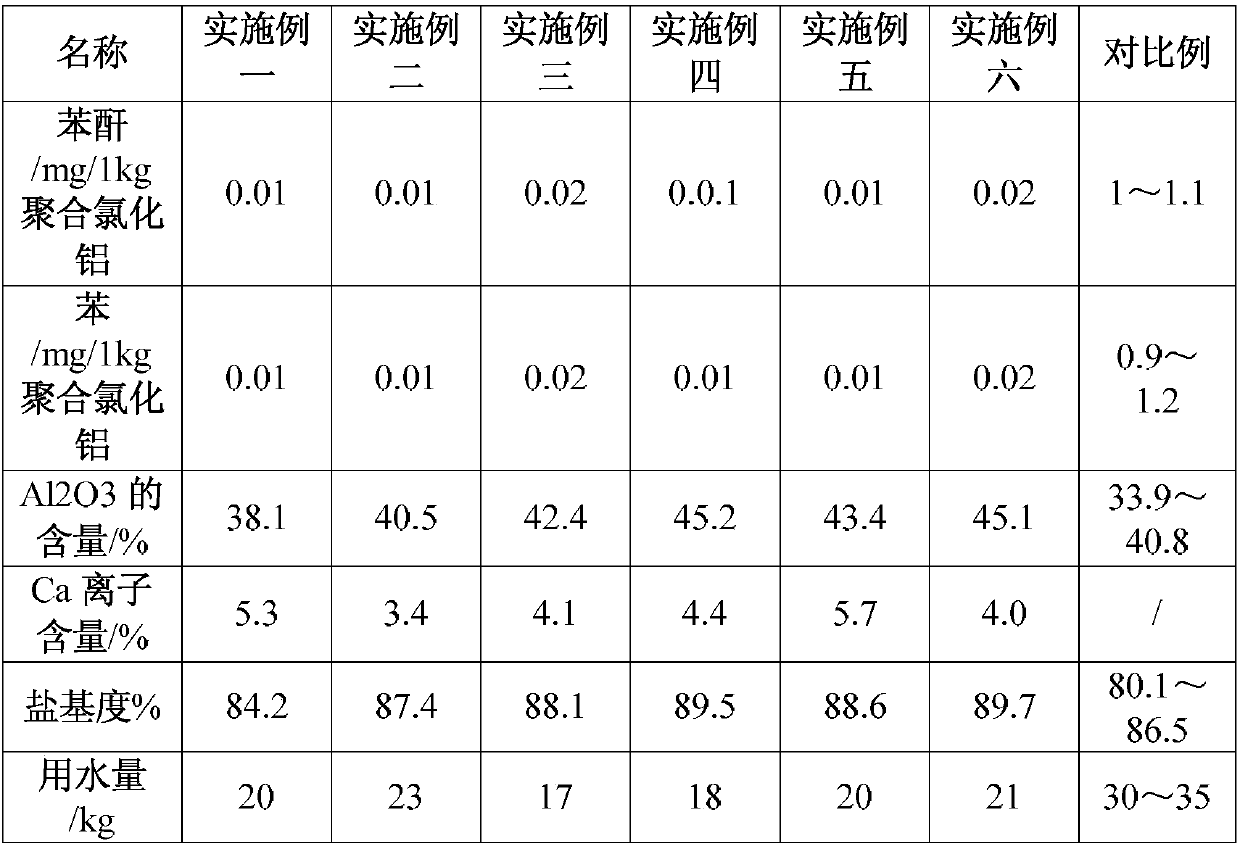

[0037] A preparation process of polyaluminum chloride, step 1: adding 100kg of BB acid mother liquor into an enamel reactor, and then slowly adding 20% of the mass fraction of Hydrogen peroxide, and keep stirring, stop adding hydrogen peroxide when gas is no longer generated; step 2: raise the temperature of the enamel to 50 ℃ ~ 60 ℃, and keep it warm for 15min ~ 30min; step 3: weigh 10kg calcium powder and add it to the BB in step 1 Add an appropriate amount of washing water to the acid mother liquor, and at the same time, control the temperature of the enamel reactor at 60°C to 70°C and keep it for 1h to 2h; Step 4: After the reaction in step 3 is completed, raise the temperature of the enamel reaction to 100°C and keep it warm for 2.5 hours to obtain light yellow flocs; Step 5: Press filter, wash and dry the light yellow flocs in sequence to finally obtain liquid polyaluminum chloride finished product; Step 6: Polymerize the liquid The aluminum chloride finished product i...

Embodiment 2

[0039] A preparation process of polyaluminum chloride, step 1: adding 100kg of BB acid mother liquor into an enamel reactor, and then slowly adding 30% of the mass fraction of BB acid mother liquor to the BB acid mother liquor at a rate of 500mL / min to 1000mL / min Hydrogen peroxide, and keep stirring, stop adding hydrogen peroxide when gas is no longer generated; Step 2: Heat the enamel to 50°C-60°C, and keep it warm for 15min-30min; Step 3: Weigh 20kg of calcium powder and add it to the BB in Step 1 Add an appropriate amount of washing water to the acid mother liquor, and at the same time, control the temperature of the enamel reactor at 60°C to 70°C and keep it for 1h to 2h; Step 4: After the reaction in step 3 is completed, raise the temperature of the enamel reaction to 110°C and keep warm for 4 hours to obtain light yellow flocs; step five: press filter, wash, and blot the light yellow flocs in sequence to finally obtain liquid polyaluminum chloride finished products and te...

Embodiment 3

[0041] A preparation process of polyaluminum chloride, step 1: adding 100kg of BB acid mother liquor into an enamel reactor, and then slowly adding 25% of the mass fraction of Hydrogen peroxide, and keep stirring, stop adding hydrogen peroxide when gas is no longer generated; step 2: raise the temperature of the enamel to 50 ℃ ~ 60 ℃, and keep it warm for 15min ~ 30min; step 3: weigh 16kg calcium powder and add it to the BB in step 1 Add an appropriate amount of washing water to the acid mother liquor, and at the same time, control the temperature of the enamel reactor at 60°C to 70°C and keep it for 1h to 2h; Step 4: After the reaction in step 3 is completed, raise the temperature of the enamel reaction to 105°C and keep warm for 3.2 hours to obtain light yellow flocs; step five: press filter, wash and dry the light yellow flocs in sequence to finally obtain liquid polyaluminum chloride finished product; step six, polymerize the liquid The aluminum chloride finished product i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com