Preparation method of nano tin antimony oxide powder

A technology of nano-tin antimony oxide and tin hydroxide, applied in chemical instruments and methods, antimony oxide/antimony hydroxide/antimony oxyacid, nanotechnology, etc., can solve the problems of slow production speed and cumbersome preparation steps, etc. Achieve the effect of convenient vibration and fast positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

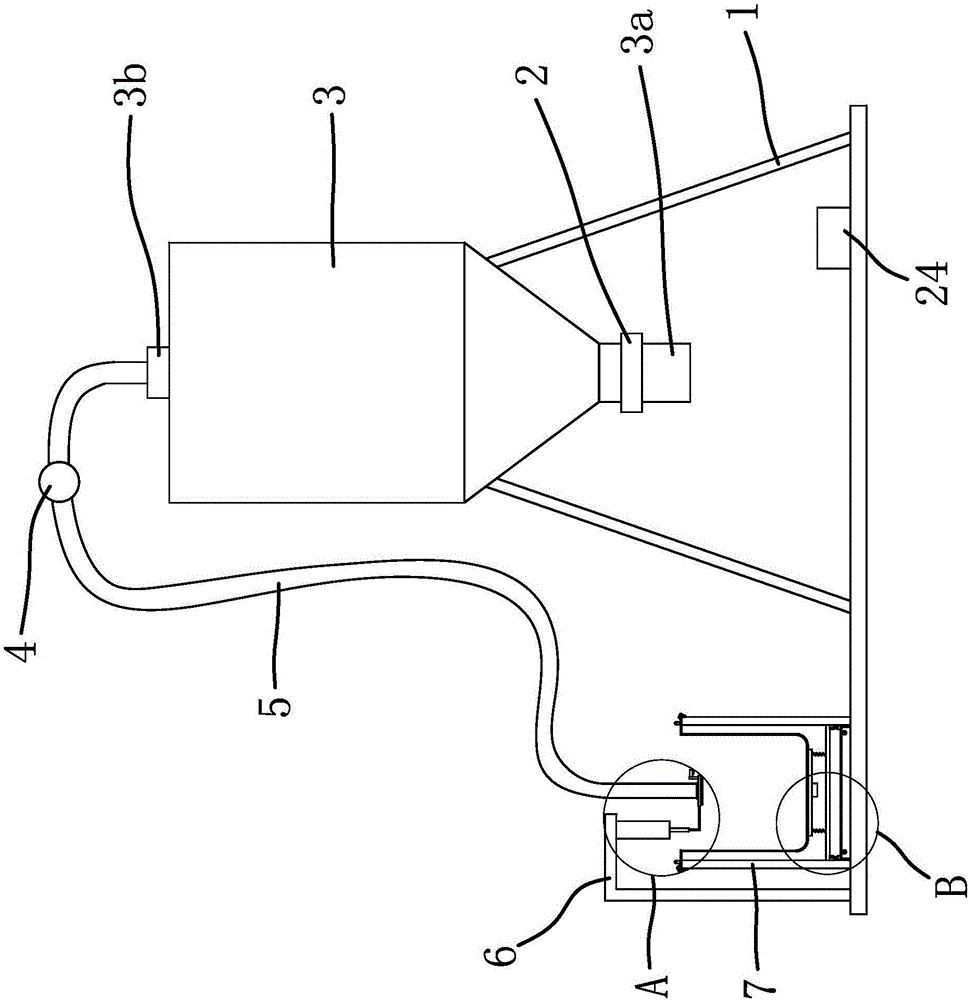

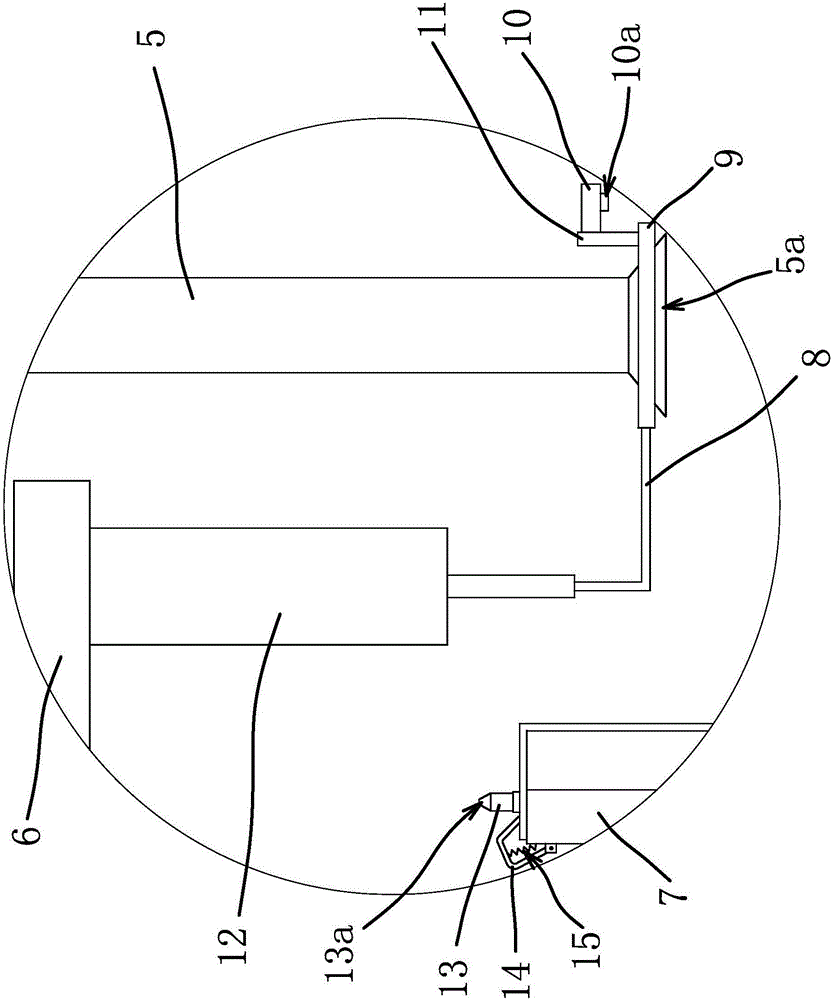

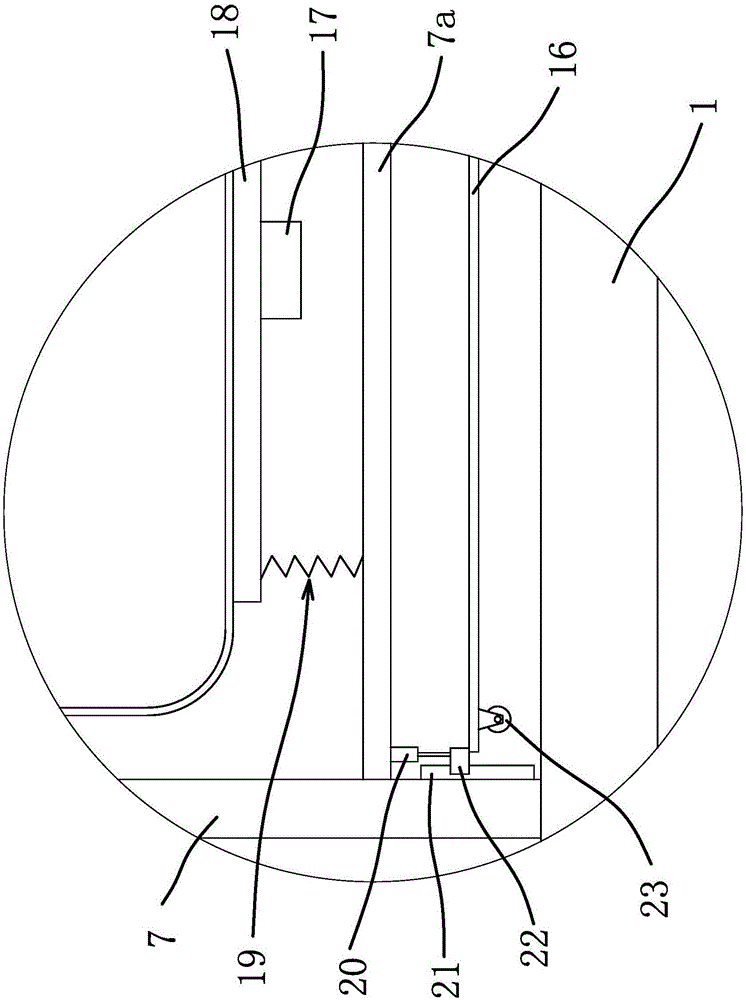

[0066] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0067] The preparation method of this nano tin antimony oxide powder is made up of the following steps:

[0068] a. Dissolve tin tetrachloride and antimony nitrate in dilute hydrochloric acid, gradually add alkali solution in the process of stirring until the pH value reaches 7-9, continue to stir until the precipitation of tin ions and antimony ions is complete, and obtain tin hydroxide and Antimony hydroxide precursor; in this embodiment, gradually add alkali solution in the process of stirring until the pH value reaches 8;

[0069] b. Separating by filtration and washing tin hydroxide and antimony hydroxide precursors with deionized water, removing soluble substances, washing 2-5 times, in this embodiment, washing 3 tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com