Preparation method of sub-micron cellulose

A cellulose and sub-micron technology, applied in the field of preparation of sub-micron cellulose, can solve the problems of high energy consumption and high cost, and achieve the effects of reducing energy consumption, low cost and avoiding a large amount of energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

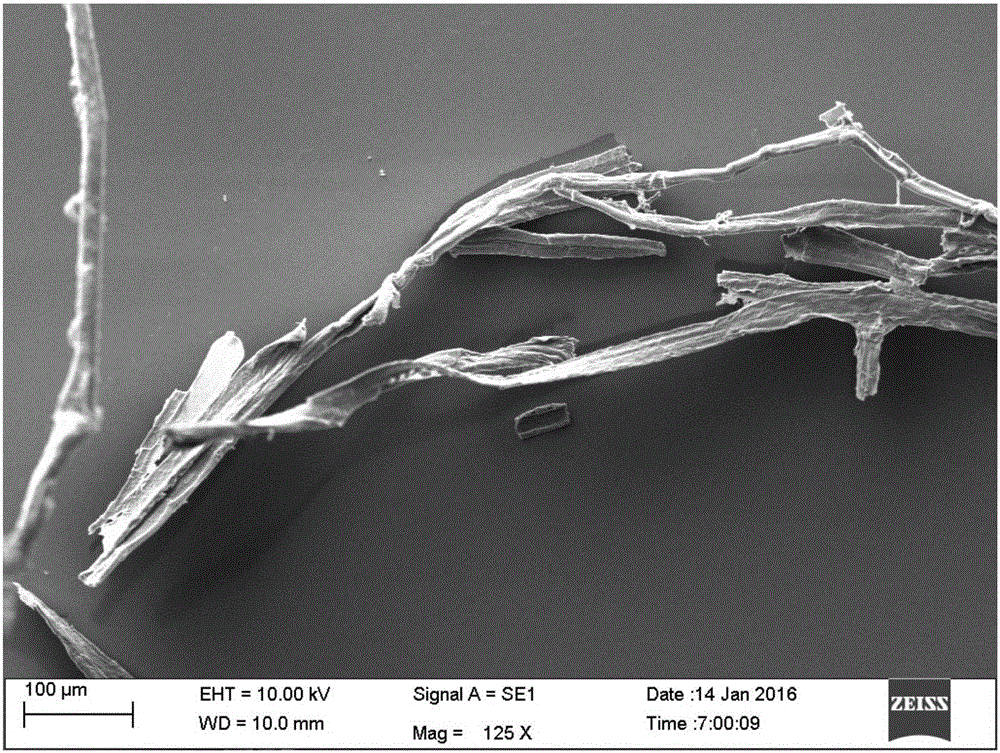

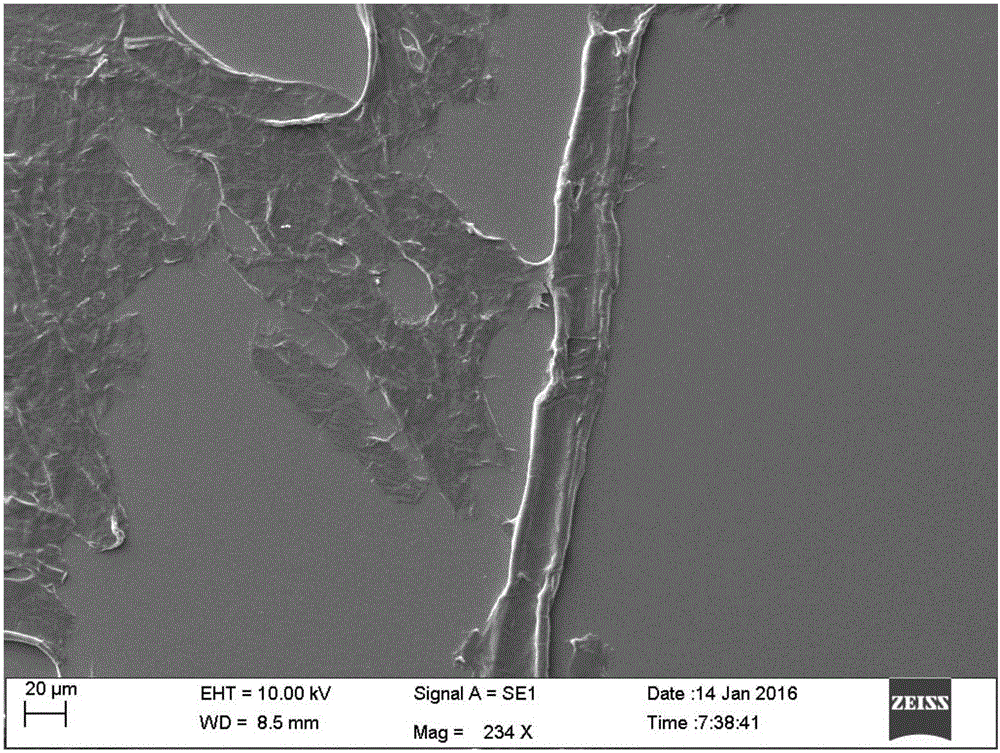

Image

Examples

Embodiment 1

[0030] A method for preparing submicron cellulose, comprising the following steps and process conditions:

[0031] (1) Drying of dissolving pulp: drying the eucalyptus dissolving pulp at 105°C until the moisture content is lower than 2%;

[0032] (2) Swelling of dissolving pulp: Mix methanol and dimethyl sulfoxide (DMSO) two solvents according to the mass ratio of 1:5 to prepare a swelling liquid, and add the swelling liquid to the dried dissolving pulp to control the swelling liquid of the dissolving pulp. The dry weight accounts for 1% by weight of the whole mixed solution.

[0033] (3) Dissociation of dissolving pulp: keep the swelling solution prepared in step (2) at 50°C and keep stirring, after stirring for 30 minutes, add KOH 1.5 times the mass of dissolving pulp, and continue stirring for 60 minutes.

[0034] (4) Modification of dissolving pulp: in step (3), add sodium acetate of 2 times of dissolving pulp quality and 1 times of sodium dipropyl acetate. At the same t...

Embodiment 2

[0039] A method for preparing submicron cellulose, comprising the following steps and process conditions:

[0040] (1) Drying of dissolving pulp: drying eucalyptus dissolving pulp at 110°C until the moisture content is lower than 2%;

[0041] (2) Swelling of dissolving pulp: Mix ethanol and dimethyl sulfoxide (DMSO) two solvents according to the mass ratio of 1:4 to prepare a swelling liquid, wherein the dried dissolving pulp is added to the swelling liquid to control the dissolution The dry weight of the slurry accounts for 3% by weight of the entire mixed solution.

[0042](3) Dissociation of the dissolving pulp: keep the swelling solution prepared in step (2) at 40°C and keep stirring for 20 minutes, then add NaOH twice the mass of the dissolving pulp, and continue stirring for 10 minutes.

[0043] (4) Modification of dissolving pulp: in step (3), add dissolving pulp quality 3 times of sodium acetate and 1 times of sodium chloroacetate. At the same time, the solution was ...

Embodiment 3

[0047] A method for preparing submicron cellulose, comprising the following steps and process conditions:

[0048] (1) Drying of dissolving pulp: drying the eucalyptus dissolving pulp at 105°C until the moisture content is lower than 2%;

[0049] (2) Swelling of dissolving pulp: Mix two solvents of methanol and water according to the mass ratio of 1:2 to prepare a swelling liquid. After the dried dissolving pulp is added to the swelling liquid, control the absolute dry weight of the dissolving pulp to account for the entire mixture. The weight ratio of the solution is 5%.

[0050] (3) Dissociation of dissolving slurry: keep the swelling liquid prepared in step (2) at 30°C and keep stirring, after stirring for 90 minutes, add KOH 4 times the mass of dissolving slurry, and continue stirring for 15 minutes.

[0051] (4) Modification of dissolving pulp: add sodium acetate 5 times of dissolving pulp quality in step (3). At the same time, the solution was kept at 50°C for 5 hours,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com