Thermochromic PBS composite wire for 3D printing

A 3D printing, thermochromic technology, applied in the field of PBS composite wire for 3D printing, can solve the problems of thermal shrinkage, toughness and tensile strength to be further improved, and achieve low shrinkage, round and full color, good tensile strength. and flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

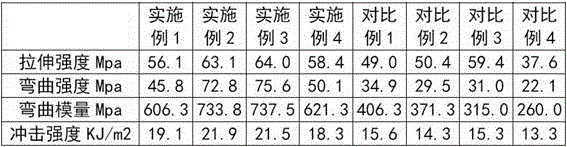

Examples

Embodiment 1

[0018] A PBS composite wire for 3D printing, which consists of the following raw materials in parts by weight: 80 parts of PBS, 2 parts of PHA, 2 parts of compatibilizer, 0.2 part of chain extender, 0.3 part of crosslinking agent, 0.5 part of nucleating agent, anti- 1 part of oxygen agent, 1 part of lubricant, 1.2 parts of multi-walled carbon nanotubes / ZnO composite powder, described multi-walled carbon nanotubes / ZnO composite powder is made of multi-walled carbon nanotubes and flower-shaped nano ZnO by weight ratio 1:2 composition.

[0019] The preparation method of this PBS composite material is as follows:

[0020] (1) Preparation of flower-shaped nano-ZnO: Weigh 0.76783g of zinc acetate dihydrate and 1.96g of sodium hydroxide into beakers A and B respectively and dissolve them with 10ml deionized water to form a transparent solution. In a cold water bath (5°C) and stirred at a constant speed, drop the sodium hydroxide solution in the beaker B into the beaker A slowly and ...

Embodiment 2

[0026] Based on Example 1, the only difference is that the multi-walled carbon nanotube / ZnO composite powder is composed of multi-walled carbon nanotubes and flower-shaped nano-ZnO in a weight ratio of 1:8. The prepared PBS composite wire was subjected to 3D printing test, the printing temperature was 145°C, the printing process was smooth, the surface of the printed product was smooth and well-proportioned, the appearance was beautiful, the size was stable and no warping.

Embodiment 3

[0028] Based on Example 1, the only difference is that the multi-walled carbon nanotube / ZnO composite powder is composed of multi-walled carbon nanotubes and flower-shaped nano-ZnO in a weight ratio of 1:15. The prepared PBS composite wire was subjected to 3D printing test, the printing temperature was 145°C, the printing process was smooth, the surface of the printed product was smooth and well-proportioned, the appearance was beautiful, the size was stable and no warping.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com