A kind of electrochromic glass and its manufacturing method

An electrochromic glass and electrochromic technology, applied in instruments, nonlinear optics, optics, etc., can solve problems affecting product quality, reduce vacuum degree and sealing of vacuum glass, and achieve high controllability of finished product quality, Excellent sound insulation and low thermal conductivity, low investment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

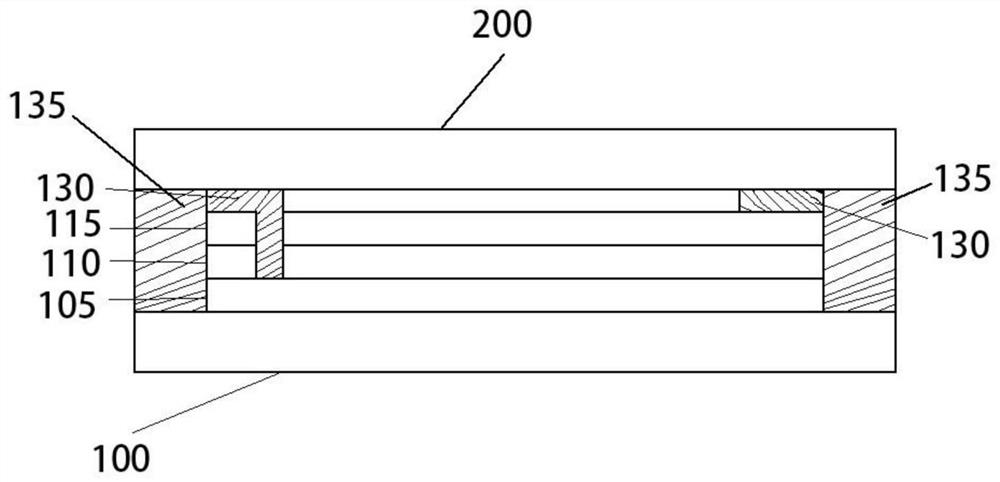

[0047] figure 1 A cross-sectional view of the structure of the electrochromic glass is shown. Such as figure 1 As shown, the present invention has a first transparent substrate 100 and a second transparent substrate 200, which are flat glass in this embodiment. In one embodiment, the first transparent substrate 100 and the second transparent substrate 200 may also be curved glass.

[0048] Between the first transparent substrate 100 and the second transparent substrate 200 , functional stacks are sequentially deposited, including the first conductive layer 105 , the electrochromic stack 110 and the second conductive layer 115 . The first conductive layer 105 and the second conductive layer 115 have a thickness of 20 to 400 nanometers (nm), in one example 20 to 50 nm, in one example 50 to 100 nm, in one example 100 to 250 nm, in An example is 300 to 400 nm, at this time the sheet resistance should be 5 to 25 ohms, and the average transmittance of visible light is >85%. Wher...

Embodiment 2

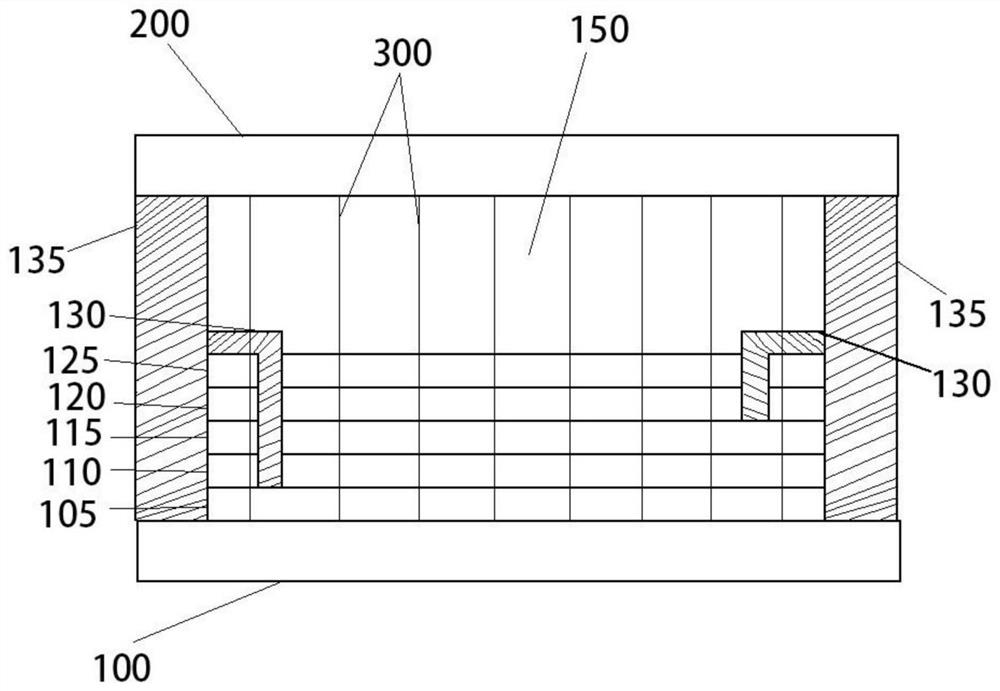

[0060] figure 2 A schematic diagram of the structure of electrochromic vacuum glass is shown, such as figure 2 shown in figure 1 On the basis of this, it also includes support pillars 300 , and the functional stack further includes an ion barrier layer 120 , an isolation layer 125 and a vacuum layer 150 .

[0061] Due to the existence of the vacuum layer 150 , in order to prevent the first transparent substrate 100 and the second transparent substrate 200 from being broken due to the difference in internal and external air pressure, the supporting pillars 300 are introduced. The supporting pillars 300 are evenly distributed and pasted on the first transparent substrate 100 in the form of an array, and the supporting pillars 300 are vertically connected to the first transparent substrate 100 and the second transparent substrate 200 . The height of the support column 300 is preferably 0.2 to 0.5 mm. It is determined according to the thickness of the vacuum layer 150 and the...

Embodiment 3

[0070] The present invention also provides a method for manufacturing electrochromic glass, comprising the following steps:

[0071] Step S101 , pasting an array of supporting pillars on a first transparent substrate.

[0072] A high-temperature-resistant adhesive is dispensed on the cleaned first transparent substrate 100 by a glue dispenser to form a regular and uniform array, and then the support columns are bonded together with the glass through the high-temperature-resistant adhesive.

[0073] Step S102, forming a functional stack, depositing an electrochromic stack on a first transparent substrate having a first conductive layer, and depositing a second conductive layer on the electrochromic stack.

[0074] The first conductive layer 105 can be directly deposited on the first transparent substrate 100 by vacuum coating, evaporation coating, sol-gel and other processes, or can be directly deposited on the first transparent substrate 100 with the first conductive layer 105...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com