High-refractive-index yellowing-resistant LED packaging silica gel

A technology of LED packaging and high refractive index, applied in the field of high refractive index LED packaging silica gel and high refractive index yellowing resistant LED packaging silica gel, can solve the problems of UV aging yellowing and other problems, achieve low temperature and UV yellowing performance, Excellent optical structure, high refractive index effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

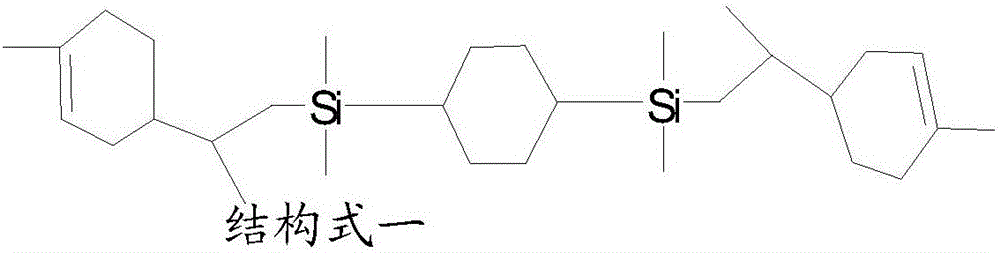

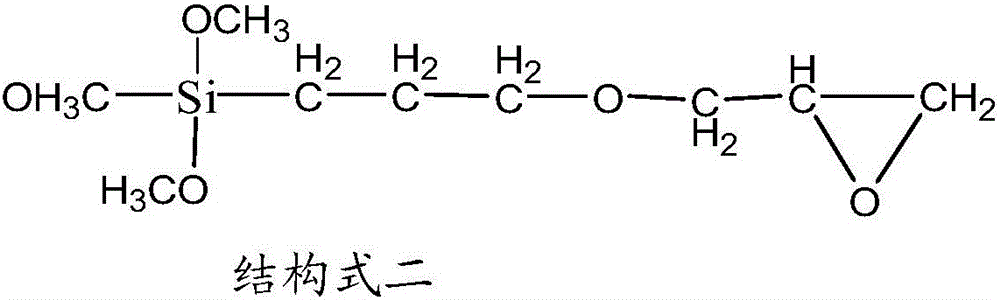

[0025] Component A includes the following raw materials in parts by weight: 80 parts of methylcyclohexylvinyl silicone resin, 18 parts of modified organosilicon (structural formula 1) containing cyclohexyl and cyclohydrocarbyl structures in the main chain terminated by cycloalkene group, platinum catalyst 0.1 part, 1.9 parts of adhesive (structural formula 2), stirred at room temperature for 2 hours, and mixed evenly;

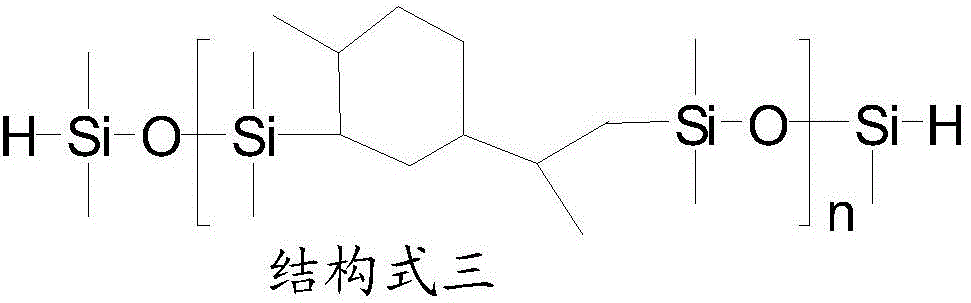

[0026] The component B includes the following raw materials in parts by weight: 50 parts of modified organosilicon (structural formula 1) whose main chain terminated by cycloalkene group contains cyclohexyl and cyclohydrocarbyl structure, and the main chain terminated by silicon hydrogen of chain extender contains cyclohydrocarbyl group. Structure modified silicone (structural formula 3) 50 parts, inhibitor (structural formula 4) 0.3 parts, stirred at room temperature for 2 hours, and mixed evenly.

Embodiment 2

[0028] Component A includes the following raw materials in parts by weight: 90 parts of methylcyclohexylvinyl silicone resin, 8 parts of modified organosilicon (structural formula 1) containing cyclohexyl and cyclohydrocarbyl structures in the main chain terminated by cycloalkenyl group, platinum catalyst 0.3 parts, 1.7 parts of adhesive (structural formula 2), stirred at room temperature for 2 hours, and mixed evenly;

[0029] The component B includes the following raw materials in parts by weight: 30 parts of modified organosilicon (structural formula 1) whose main chain terminated by a cycloalkene group contains cyclohexyl and cyclohydrocarbyl structures, and the main chain terminated by a chain extender containing a hydrosilyl group contains a cyclohydrocarbyl group. Structure modified silicone (structural formula 3) 70 parts, inhibitor (structural formula 4) 0.1 part, stir at room temperature for 2 hours, and mix well.

Embodiment 3

[0031] Component A includes the following raw materials in parts by weight: 85 parts of methylcyclohexylvinyl silicone resin, 13 parts of modified organosilicon (structural formula 1) containing cyclohexyl and cyclohydrocarbyl structures in the main chain terminated by cycloalkenyl group, platinum catalyst 0.2 parts, 1.8 parts of adhesive (structural formula 2), stirred at room temperature for 2 hours, and mixed evenly;

[0032] The component B includes the following raw materials in parts by weight: 40 parts of modified silicone (structural formula 1) whose main chain terminated by a cycloalkene group contains cyclohexyl and cyclohydrocarbyl structures, and the main chain terminated by a chain extender containing a hydrosilyl group contains a cyclohydrocarbyl group. 60 parts of modified organosilicon (structural formula 3), 0.2 part of inhibitor (structural formula 4), stirred at room temperature for 2 hours, and mixed uniformly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com