Family car control arm aluminum-magnesium-silicon alloy and preparation method thereof

A technology for household automobiles and aluminum-magnesium-silicon is applied in the field of aluminum-silicon-magnesium alloys, which can solve the problems of suboptimal alloy formula, reduced corrosion resistance, and increased production costs, and achieves improved corrosion resistance, reduced weight, and saved costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

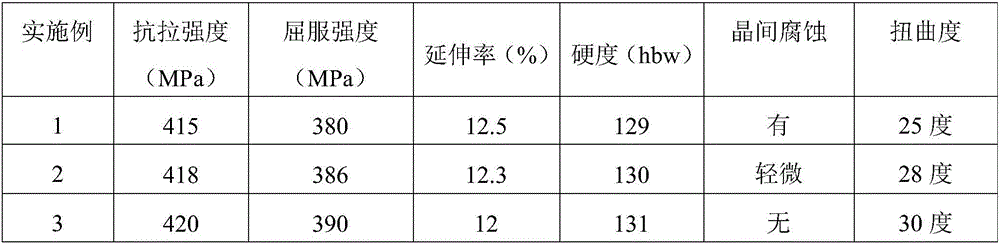

Examples

Embodiment 1

[0024] The applicant provides an aluminum-magnesium-silicon alloy for the control arm of a family car, which is composed of the following raw materials: silicon: 110kg, copper: 4kg, manganese: 70kg, magnesium: 70kg, chromium: 16kg, zirconium: 2kg, aluminum: 9728kg .

[0025] The preparation method of the aluminum-magnesium-silicon alloy is:

[0026] (1) First put the aluminum ingot into the melting furnace for melting, the melting temperature control range is 760°C, and the melting time is 3 hours, open the furnace door and rake the ash into the bottom of the furnace to see if it is completely melted; after all the materials in the furnace are completely melted , turn on the electromagnetic stirring device, and stir for 15 minutes;

[0027] (2) Then add refining agent, carry out refining for 20 minutes to molten aluminum for the first time with the nitrogen of pressure 0.08-0.12Mpa, then carry out slag removal;

[0028] (3) After removing slag, add copper, manganese, chromiu...

Embodiment 2

[0034] The applicant provides an aluminum-magnesium-silicon alloy for the control arm of a family car, which is composed of the following raw materials: silicon: 125kg, copper: 8kg, manganese: 85kg, magnesium: 90kg, chromium: 20kg, zirconium: 4kg, aluminum: 9668kg .

[0035] The preparation method of the aluminum-magnesium-silicon alloy is:

[0036] (1) First put the aluminum ingot into the melting furnace for melting, the melting temperature control range is 720°C, and the melting time is 4 hours, open the furnace door and rake the ash into the bottom of the furnace to see if it is completely melted; after all the materials in the furnace are completely melted , turn on the electromagnetic stirring device, and stir for 20 minutes;

[0037] (2) Then add refining agent, carry out refining for 15 minutes to molten aluminum for the first time with the nitrogen of pressure 0.08-0.12Mpa, then carry out slag removal;

[0038] (3) After removing slag, add copper, manganese, chromiu...

Embodiment 3

[0044] The applicant provides an aluminum-magnesium-silicon alloy for the control arm of a family car, which is composed of the following raw materials: silicon: 119kg, copper: 6kg, manganese: 80kg, magnesium: 80kg, chromium: 18kg, zirconium: 3kg, aluminum: 9694kg .

[0045] The preparation method of the aluminum-magnesium-silicon alloy is:

[0046] (1) First put the aluminum ingot into the melting furnace for melting, the melting temperature control range is 740°C, and the melting time is 3.5 hours. Open the furnace door and rake the ash into the bottom of the furnace to see if it is completely melted; after all the materials in the furnace are completely melted , turn on the electromagnetic stirring device, and stir for 18 minutes;

[0047] (2) Then add a refining agent, use nitrogen with a pressure of 0.08-0.12Mpa to refine the aluminum liquid for the first time for 15-20 minutes, and then carry out slag removal;

[0048] (3) After removing slag, add copper, manganese, ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com