A method of growing high-quality silicon carbide whiskers

A silicon carbide whisker, high-quality technology, applied in chemical instruments and methods, single crystal growth, single crystal growth, etc., can solve the problems of complex growth process and unstable whisker, and achieve strong operability and low production cost , cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

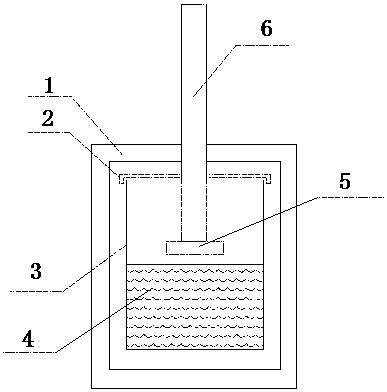

Image

Examples

Embodiment 1

[0022] First put the graphite crucible with polysilicon raw material into the vacuum furnace, then evacuate the vacuum furnace chamber to 0Pa, then fill the furnace with argon gas to 0.5 atm, then heat the graphite crucible, and slowly raise the temperature to 1420°C until the polysilicon melts. Continue to raise the temperature to 1500°C and keep it warm for 30 minutes to make the molten silicon corrode the graphite crucible, thereby obtaining a silicon carbide solution. Then immerse the silicon carbide whisker collection rod and collection plate into the silicon carbide solution in the graphite crucible, keeping the collection plate 3cm away from the liquid surface for 3 hours to obtain 3C-SiC whiskers with a diameter of 500μm and a length of 2cm.

Embodiment 2

[0024] First, put the graphite crucible with polysilicon raw material into the vacuum furnace, then evacuate the vacuum furnace chamber to 0Pa, then fill the furnace with argon gas to 1 atm, then heat the graphite crucible, and slowly raise the temperature to 1420 °C until the polysilicon melts. Continue to raise the temperature to 1500°C and keep it warm for 30 minutes to make the molten silicon corrode the graphite crucible, thereby obtaining a silicon carbide solution. Then immerse the silicon carbide whisker collection rod and collection plate into the silicon carbide solution in the graphite crucible, keep the collection plate 3 cm away from the liquid surface, and keep it for 6 hours to obtain 3C-SiC whiskers with a diameter of 500 μm and a length of 4 cm.

Embodiment 3

[0026] First put the graphite crucible with polysilicon raw material into the vacuum furnace, then evacuate the vacuum furnace chamber to 0Pa, then fill the furnace with helium to 0.7atm, then heat the graphite crucible, and slowly raise the temperature to 1420°C until the polysilicon melts. Continue to raise the temperature to 1700°C and keep it warm for 30 minutes to make the molten silicon corrode the graphite crucible to obtain a silicon carbide solution. Then immerse the silicon carbide whisker collection rod and collection plate into the silicon carbide solution in the graphite crucible, keep the collection plate 1 cm away from the liquid surface, and keep it for 3 hours to obtain 4H-SiC whiskers with a diameter of 600 μm and a length of 3 cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com