Preparation and application of Pd-doped SnO2-oxide-semiconductor CO sensor

An oxide semiconductor and sensor technology, applied in instruments, scientific instruments, measuring devices, etc., can solve the problems of high detection lower limit and low sensitivity of sensors, and achieve the effects of low detection lower limit, high sensitivity and simple method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

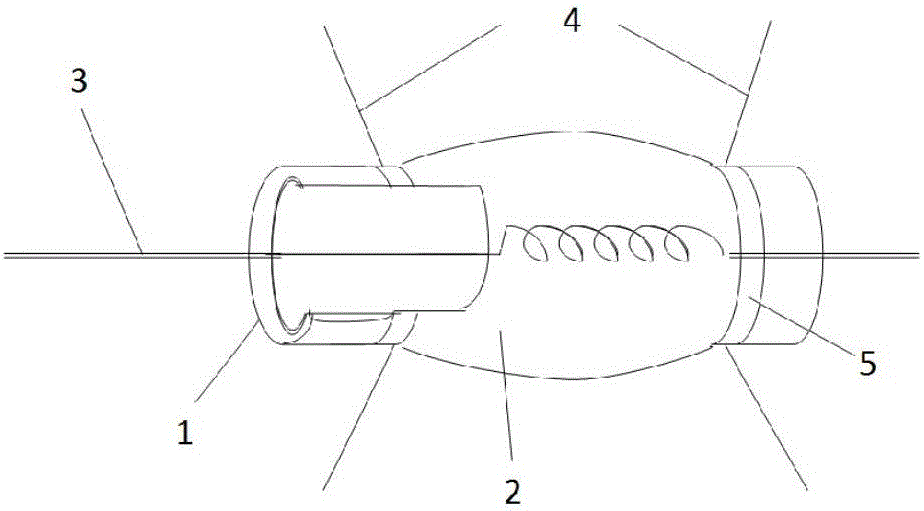

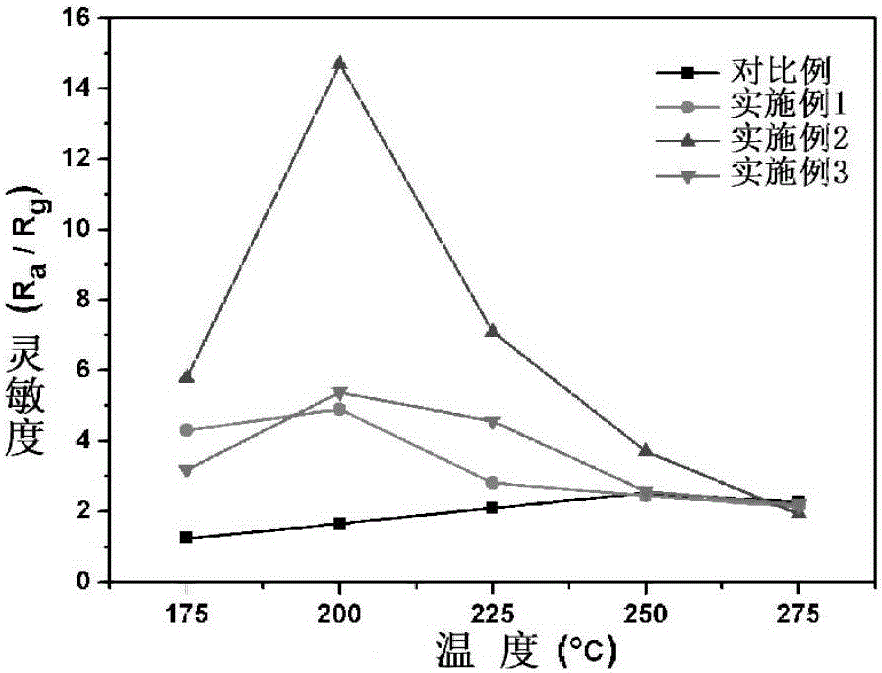

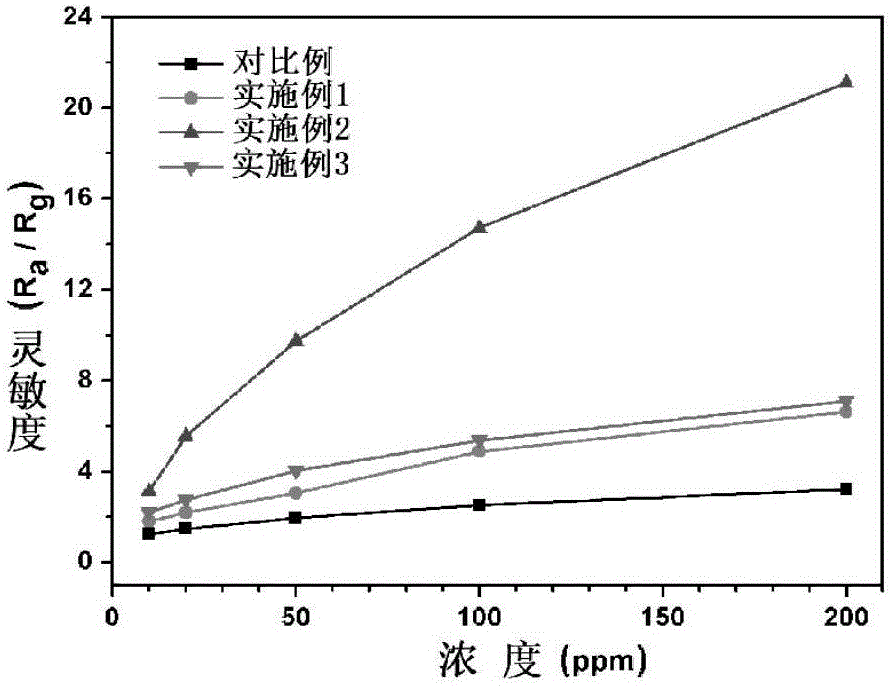

[0037] Pd-doped SnO with a mass ratio of element Pd / Sn in the reactant of 0.015:1 2 Oxide semiconductors are used as sensitive materials to make side-heated carbon monoxide sensors. The specific manufacturing process:

[0038] (1) First add 42mg K 2 SnO 3 .3H 2 O, 180mg urea, 5ml ethanol, 5ml water were stirred for 10 minutes to form a homogeneous solution, and a certain amount of PdCl 2 Added to the above solution so that the mass ratio of element Pd and element Sn is 1.5wt%;

[0039] (2) Put the mixed solution of (1) into a 45ml polytetrafluoroethylene kettle and seal it, put it in an oven at 150°C for 24 hours, cool down to room temperature naturally after the end, collect the samples with ethanol and deionized water and centrifuge them and place them in the culture Keep the dish at 80°C for 12 hours and collect the samples;

[0040] (3) Calcining the above-mentioned nanometer gas-sensitive material at 500°C for 2 hours to obtain a gas-sensitive material, mixing the se...

Embodiment 2

[0043] Doping SnO with Pd with a mass ratio of element Pd / Sn of 0.030:1 in the reactant 2 Oxide semiconductors are used as sensitive materials to make side-heated carbon monoxide sensors. The specific manufacturing process:

[0044] (1) First add 42mg K 2 SnO 3 .3H 2 O, 180mg urea, 5ml ethanol, 5ml water were stirred for 10 minutes to form a homogeneous solution, and a certain amount of PdCl 2 Added to the above solution so that the mass ratio of element Pd and element Sn is 3.0wt%;

[0045] (2) Put the mixed solution of (1) into a 45ml polytetrafluoroethylene kettle and seal it, put it in an oven at 150°C for 24 hours, cool down to room temperature naturally after the end, collect the samples with ethanol and deionized water and centrifuge them and place them in the culture Keep the dish at 80°C for 12 hours and collect the samples;

[0046] (3) Calcining the above-mentioned nanometer gas-sensitive material at 500°C for 2 hours to obtain a gas-sensitive material, mixing ...

Embodiment 3

[0049] Pd-doped SnO with a mass ratio of element Pd / Sn in the reactant of 0.045:1 2 Oxide semiconductors are used as sensitive materials to make side-heated carbon monoxide sensors. The specific manufacturing process:

[0050] (1) First add 42mg K 2 SnO 3 .3H 2 O, 180mg urea, 5ml ethanol, 5ml water were stirred for 10 minutes to form a homogeneous solution, and a certain amount of PdCl 2 Added to the above solution so that the mass ratio of element Pd and element Sn is 4.5wt%;

[0051] (2) Put the mixed solution of (1) into a 45ml polytetrafluoroethylene kettle and seal it, put it in an oven at 150°C for 24 hours, cool down to room temperature naturally after the end, collect the samples with ethanol and deionized water and centrifuge them and place them in the culture Keep the dish at 80°C for 12 hours and collect the samples;

[0052] (3) Calcining the above-mentioned nanometer gas-sensitive material at 500°C for 2 hours to obtain a gas-sensitive material, mixing the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com