Surface treatment method for sic substrates, sic substrate, and semiconductor production method

A surface treatment and substrate technology, applied in semiconductor/solid-state device manufacturing, semiconductor device, post-processing, etc., can solve problems such as grinding damage to SiC substrates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

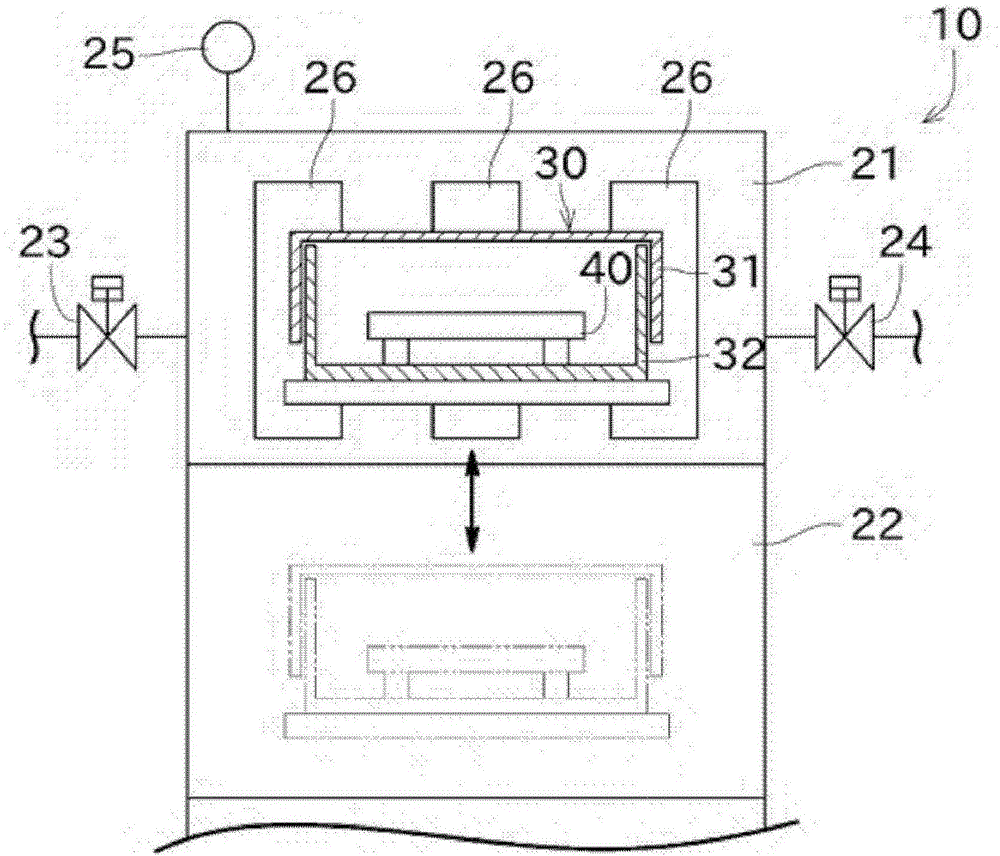

[0049] First, refer to figure 1 The high-temperature vacuum furnace 10 used for the heat treatment of this embodiment will be described. figure 1 It is a figure explaining the outline|summary of the high temperature vacuum furnace used for the surface treatment method of this invention.

[0050] Such as figure 1 As shown, the high-temperature vacuum furnace 10 has a main heating chamber 21 and a preliminary heating chamber 22 . The main heating chamber 21 can heat a SiC substrate having at least a surface made of single crystal SiC to a temperature of 1000° C. or higher and 2300° C. or lower. The preliminary heating chamber 22 is a space for performing preliminary heating before the main heating chamber 21 heats the SiC substrate.

[0051] The main heating chamber 21 is connected to a vacuum forming valve 23 , an inert gas injection valve 24 and a vacuum gauge 25 . ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com