Globe artichoke yoghourt and making method thereof

A technology for artichoke and yogurt, applied in the field of artichoke yogurt and its preparation, can solve the problem of not combining artichoke and yogurt to make health yogurt, etc., and achieve the effects of improving cholesterol-lowering effect, fresh and unique flavor, and delicate taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 1) Dry and crush the clean artichoke stems and leaves to 20 meshes, add 8 times the amount of 60°C water, extract with 700W microwave for 90s, concentrate the extract to obtain artichoke extract; then carry out macroporous adsorption resin separation and purification: The pretreated LSA-21 resin is loaded into the glass chromatography, the artichoke extract is loaded according to the volume flow rate of 2BV / h, and 3BV of 50% ethanol is eluted, and the elution rate is 2BV / h, and the obtained eluate Concentrate into a clear paste with a relative density of 1.10-1.30 at 50°C, freeze-dry for 72 hours to obtain freeze-dried artichoke powder, wherein the content of artichoke acid is 5%;

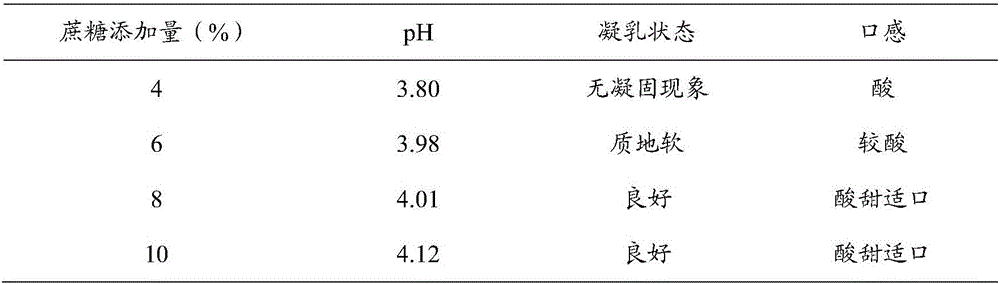

[0022] 2) According to the mass ratio of whole milk powder to water of 9:100, dissolve whole milk powder in warm water at 40°C, add 6% sucrose, mix well, filter, sterilize at 90°C for 15 minutes, and sterilize Then quickly cool the milk to 40°C;

[0023] 3) Mix the freeze-dried artichoke po...

Embodiment 2

[0027] 1) Dry and crush the clean artichoke stems and leaves to 20 meshes, add 8 times the amount of 60°C water, extract with 700W microwave for 90s, concentrate the extract to obtain artichoke extract; then carry out macroporous adsorption resin separation and purification: The pretreated LSA-21 resin is loaded into the glass chromatography, the artichoke extract is loaded according to the volume flow rate of 2BV / h, and 3BV of 50% ethanol is eluted, and the elution rate is 2BV / h, and the obtained eluate Concentrate into a clear paste with a relative density of 1.10-1.30 at 50°C, freeze-dry for 72 hours to obtain freeze-dried artichoke powder, wherein the content of artichoke acid is 5%;

[0028] 2) According to the mass ratio of whole milk powder to water of 9:100, dissolve whole milk powder in warm water at 40°C, add 8% sucrose, mix well, filter, sterilize at 90°C for 15 minutes, and sterilize Then quickly cool the milk to 40°C;

[0029] 3) Mix the artichoke freeze-dried po...

Embodiment 3

[0033] 1) Dry and crush the clean artichoke stems and leaves to 20 meshes, add 8 times the amount of 60°C water, extract with 700W microwave for 90s, concentrate the extract to obtain artichoke extract; then carry out macroporous adsorption resin separation and purification: The pretreated LSA-21 resin is loaded into the glass chromatography, the artichoke extract is loaded according to the volume flow rate of 2BV / h, and 3BV of 50% ethanol is eluted, and the elution rate is 2BV / h, and the obtained eluate Concentrate into a clear paste with a relative density of 1.10-1.30 at 50°C, freeze-dry for 72 hours to obtain freeze-dried artichoke powder, wherein the content of artichoke acid is 5%;

[0034] 2) According to the mass ratio of whole milk powder to water of 9:100, dissolve whole milk powder in warm water at 40°C, add 10% sucrose, mix well, filter, sterilize at 90°C for 15 minutes, and sterilize Then quickly cool the milk to 40°C;

[0035] 3) Mix the freeze-dried artichoke p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com