Rotational flow type spiral sedimentation device with automatic control system sludge discharge function

A technology of automatic control system and sedimentation device, which is applied in the feeding/discharging device of sedimentation tank, sedimentation separation, flocculation/sedimentation water/sewage treatment, etc. It is difficult to achieve water treatment effect, difficult to have solid-liquid separation efficiency and other problems, to achieve the effect of improving solid-liquid separation efficiency, flexible operation flexibility and stability, and increasing hydraulic retention time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

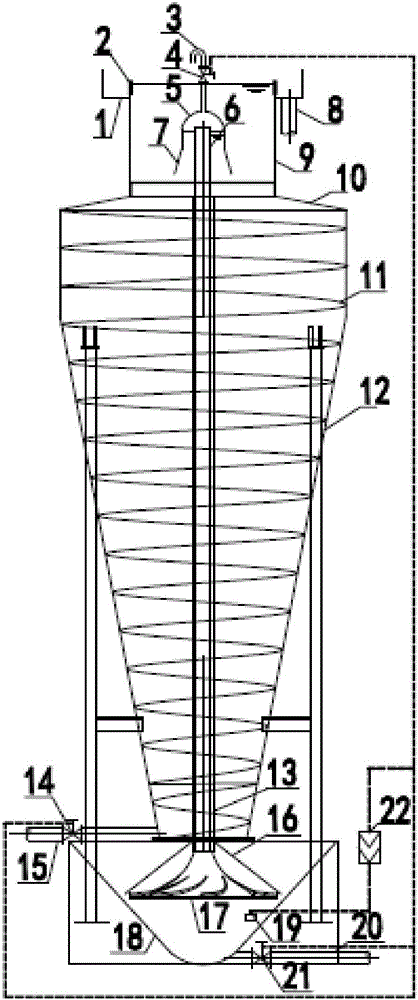

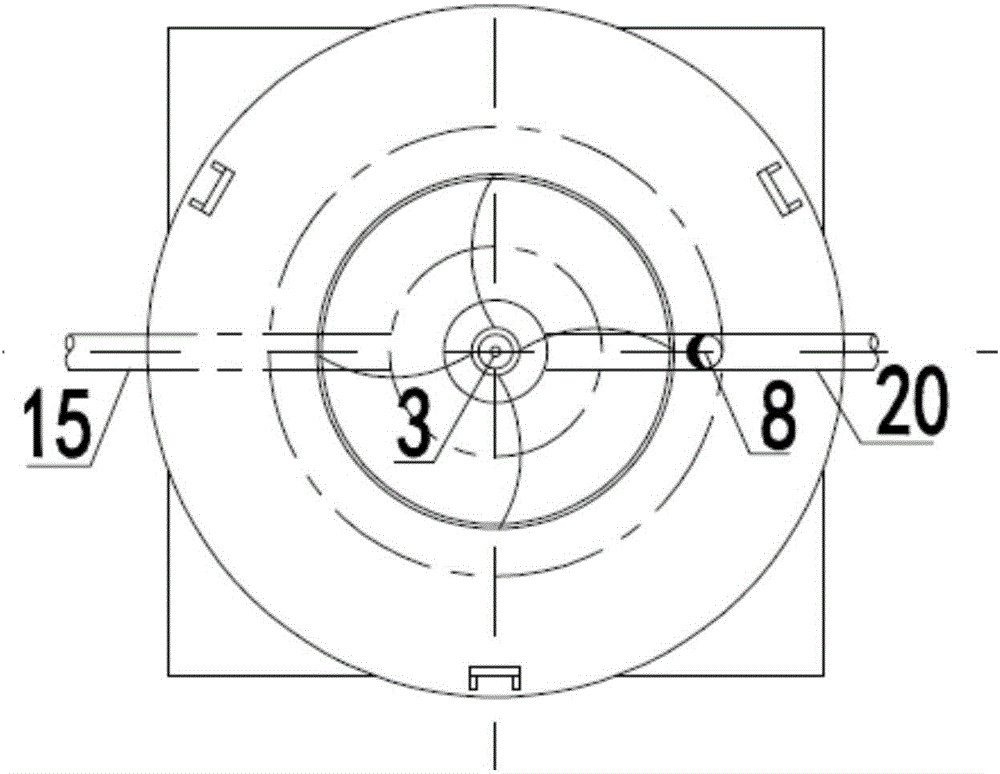

[0034] The technical solution of the present invention will be further described in conjunction with the accompanying drawings. figure 1 and figure 2 The basic structure of the present invention is shown.

[0035] As shown in the drawings, the raw water to be separated from solid and liquid enters the inverted cone 12 of the cyclone sedimentation device through the water inlet pipe 15, the flow rate is controlled by the water inlet pipe control valve 14, and the fluid spirals upward through the fixed guide spiral piece 11. At this time The solid particles in the fluid are reduced by gravity and impact, and fall on 11, most of them will move in the opposite direction with the fluid under the action of gravity, and slowly flow into the lower cone 18 of the mud deposit, and the remaining small part will Reach a speed balance with the fluid, and temporarily stay on 11; the fluid continuously rises through 11 and enters the cylinder 10 of the cyclone sedimentation device. At this...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com