Light high-aluminum heat preservation refractory brick and production method thereof

A production method and technology of refractory bricks are applied in the field of thermal insulation and refractory materials, which can solve the problems of inability to grasp the shrinkage rate of semi-finished products, environmental damage to operators, dust and noise pollution, etc., so as to save production time, improve yield, and avoid dust and noise. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

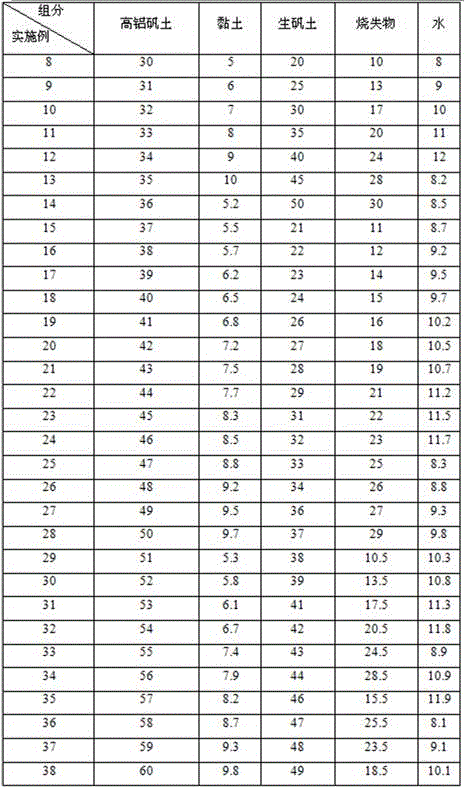

[0011] A light-weight high-alumina thermal insulation refractory brick, which is composed of the following raw materials in parts by weight: 30-60 parts of high-alumina bauxite, 5-10 parts of clay, 20-50 parts of raw bauxite, 10-30 parts of burnt matter, and 8 parts of water -12 servings.

[0012] The high alumina bauxite is 180 mesh high alumina fine powder, and the clay is 180 mesh clay fine powder.

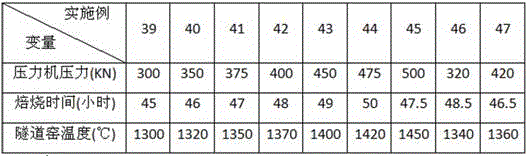

[0013] The burnt matter is carbonate.

[0014] A production method of the light-weight high-alumina thermal insulation refractory bricks, comprising the following steps: (1) mixing high-alumina bauxite, clay, raw bauxite and burnt matter in proportion; (2) mixing them in proportion to Add water to the raw material to make mud; (3) The press applies a pressure of 300-500KN to the mud through the mold to form it; (4) After passing through the drying kiln at 80-200°C, it enters the tunnel kiln and roasts for 45-50 Hours, the temperature of the tunnel kiln is 1300-1450°C; (5) Aft...

Embodiment 2

[0017] A light-weight high-alumina thermal insulation refractory brick, which is composed of the following raw materials in parts by weight: 40-50 parts of high-alumina bauxite, 6-9 parts of clay, 30-40 parts of raw bauxite, 15-25 parts of burnt matter, and 9 parts of water -11 copies.

[0018] The high alumina bauxite is 180 mesh high alumina fine powder, and the clay is 180 mesh clay fine powder.

[0019] The burnt matter is carbonate.

[0020] A production method of the light-weight high-alumina thermal insulation refractory bricks, comprising the following steps: (1) mixing high-alumina bauxite, clay, raw bauxite and burnt matter in proportion; (2) mixing them in proportion to Add water to the raw material to make mud; (3) The press applies a pressure of 350-450KN to the mud through the mold to form it; (4) After passing through the drying kiln at 80-200°C, it enters the tunnel kiln for 46-49 Hours, the temperature of the tunnel kiln is 1350-1400°C; (5) After sintering, ...

Embodiment 3

[0023] A light-weight high-alumina thermal insulation refractory brick is composed of the following raw materials in parts by weight: 45 parts of high-alumina bauxite, 7 parts of clay, 35 parts of raw bauxite, 20 parts of burnt matter, and 10 parts of water.

[0024] The high alumina bauxite is 180 mesh high alumina fine powder, and the clay is 180 mesh clay fine powder.

[0025] The burnt matter is carbonate.

[0026] A production method of the light-weight high-alumina thermal insulation refractory bricks, comprising the following steps: (1) mixing high-alumina bauxite, clay, raw bauxite and burnt matter in proportion; (2) mixing them in proportion to Add water to the raw material to make mud; (3) The press applies a pressure of 400KN to the mud through the mold to form it; (4) After passing through the drying kiln at 80-200°C, it is baked in the tunnel kiln for 48 hours, and the tunnel kiln The temperature is 1375°C; (5) After sintering, it is naturally cooled and packaged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com