Edetic acid pressurization recrystallization method

An ethylenediaminetetraacetic acid, recrystallization technology, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry and other directions, can solve the problems of high consumption, difficult to meet demand, complicated processes, etc., and achieve low energy consumption and high quality. Stable and less wasteful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

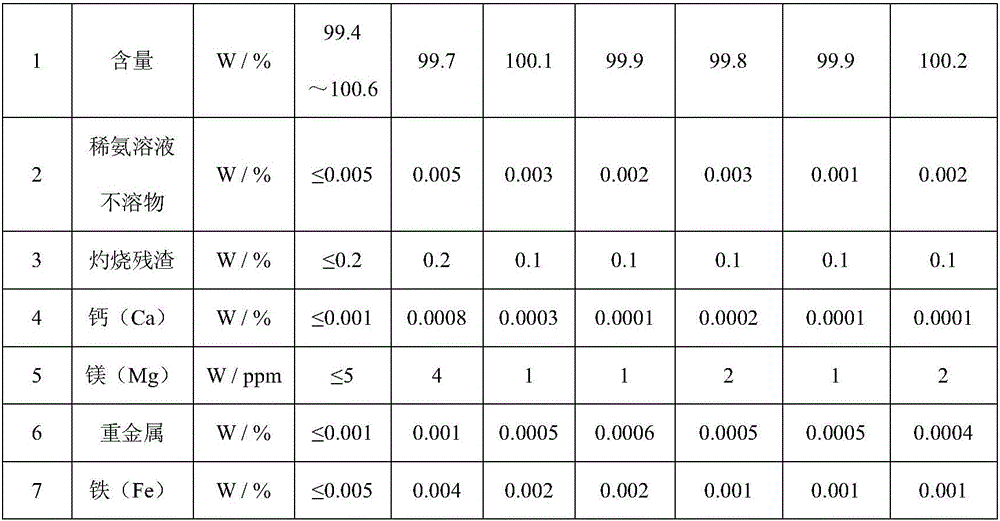

Embodiment 1

[0024] Add deionized water and ethylenediaminetetraacetic acid into the reaction device equipped with a stirrer, temperature controller and pressure gauge, the mass ratio of deionized water and ethylenediaminetetraacetic acid is 20:1, then connect nitrogen, first pass Nitrogen drives the air in the kettle clean, closes the vent valve of the reaction kettle, and then continues to pass nitrogen until the pressure in the kettle is 1 MPa, and closes the nitrogen valve. Turn on heating, start stirring when the temperature rises to 120°C, stop heating and stirring after stirring for 1 hour, open the reaction kettle when the temperature in the kettle drops to 25°C, take out the crystallized ethylenediaminetetraacetic acid, centrifuge the crystallization and separate the solution , and dried at 130°C for 3h to obtain white needle-like crystals with a yield of 93.5%. The analysis results showed that all the indicators of the EDTA recrystallized under pressure were in line with the Amer...

Embodiment 2

[0026] Add deionized water and ethylenediaminetetraacetic acid into the reaction device equipped with a stirrer, temperature controller and pressure gauge, the mass ratio of deionized water and ethylenediaminetetraacetic acid is 4:1, then connect nitrogen, first pass Nitrogen drives the air in the kettle clean, closes the vent valve of the reaction kettle, and then continues to vent nitrogen until the pressure in the kettle is 2MPa, and closes the nitrogen valve. Turn on heating, start stirring when the temperature rises to 180°C, stop heating and stirring after stirring for 3 hours, open the reaction kettle when the temperature in the kettle drops to 25°C, take out the crystallized ethylenediaminetetraacetic acid, and centrifuge the crystallization to separate the solution , and dried at 120°C for 4h to obtain white needle-like crystals with a yield of 96.1%. The analysis results showed that all the indicators of the EDTA recrystallized under pressure were in line with the Am...

Embodiment 3

[0028] Add deionized water and ethylenediaminetetraacetic acid into the reaction device equipped with a stirrer, temperature controller and pressure gauge, the mass ratio of deionized water and ethylenediaminetetraacetic acid is 7:1, then connect nitrogen, first pass Nitrogen drives off the air in the still, closes the vent valve of the reaction kettle, then continues to feed nitrogen until the pressure in the still is 1.5MPa, and closes the nitrogen valve. Turn on heating, start stirring when the temperature rises to 160°C, stop heating and stirring after stirring for 2 hours, open the reaction kettle when the temperature in the kettle drops to 28°C, take out the crystallized ethylenediaminetetraacetic acid, and centrifuge the crystallization solution Afterwards, it was dried at 80°C for 8 hours to obtain white needle-like crystals with a yield of 93.5%. The analysis results showed that all the indicators of the EDTA recrystallized under pressure were in line with the America...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com