Environmentally friendly automobile noise and heat insulation material and processing method thereof

A heat insulation material and processing method technology, applied in the field of auto parts, can solve the problems of reducing the content of aldehydes and benzene series and high VOC content in automotive interiors, so as to reduce the content of aldehydes and benzene series and solve the problem of VOC content high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

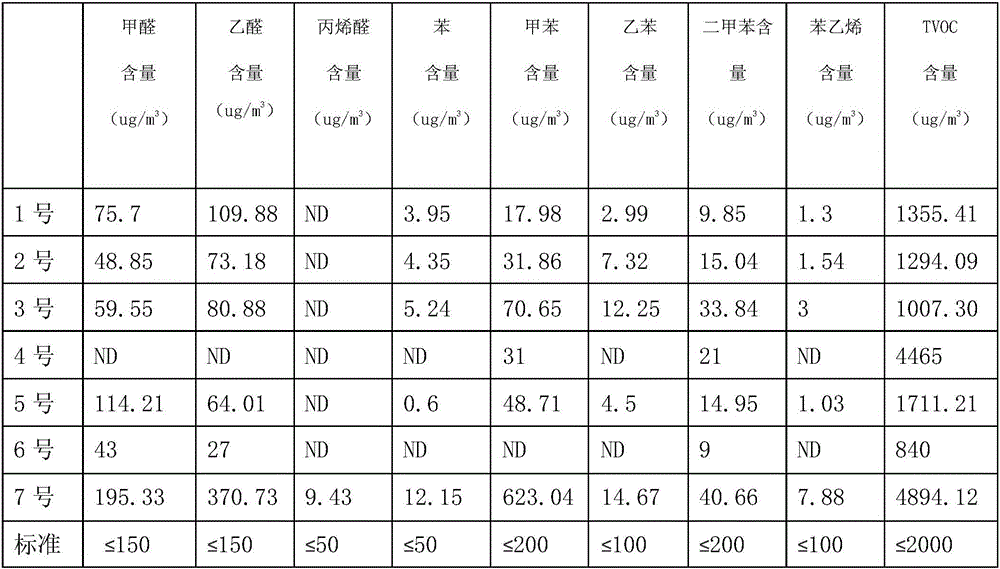

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] An environment-friendly sound-insulating and heat-insulating material for automobiles, comprising the following raw materials in the weight ratio, 50 parts of calcium carbonate, 22 parts of DF740 elastomer, 7 parts of 100# white oil, TiO 2 0.5 servings.

Embodiment 2

[0022] An environment-friendly sound-insulating and heat-insulating material for automobiles, comprising the following raw materials in the weight ratio, 70 parts of barium sulfate, 10 parts of DF740 elastomer, 2 parts of 100# white oil, TiO 2 0.1 part.

Embodiment 3

[0024] An environment-friendly sound-insulating and heat-insulating material for automobiles, comprising the following raw materials by weight: 40 parts of barium sulfate, 20 parts of calcium carbonate, 15 parts of DF740 elastomer, 5 parts of 100# white oil, 0.3 part of CdS, and 6.7 parts of PE.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com