Method for preparing selenium-rich compound fruit wine

A compound fruit wine and selenium-enriched technology, which is applied in food processing and biological fields, can solve the problems of less nutrition and health care substances, complicated process, low utilization rate of raw materials, etc., and achieve the effect of improving utilization rate and unique taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

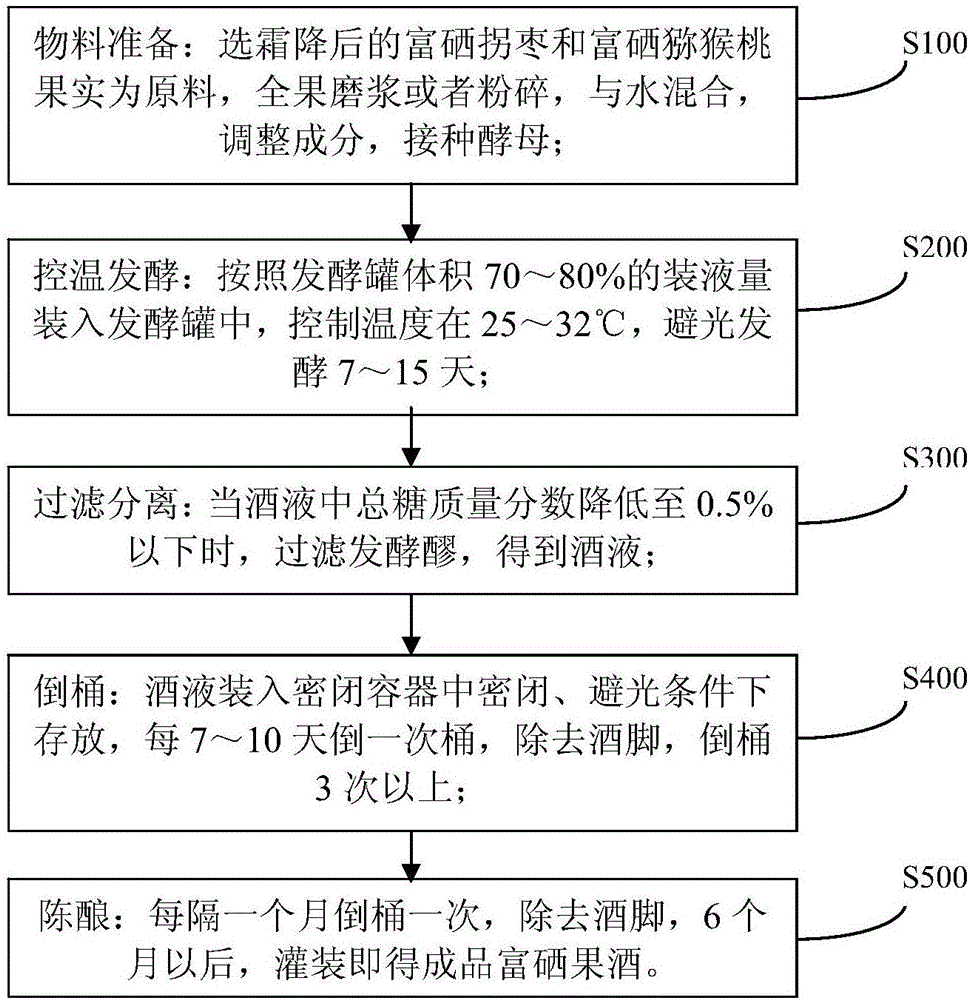

[0026] figure 1 Show the flow process of the preferred embodiment of the preparation method of selenium-enriched compound fruit wine of the present invention, as figure 1 shown, including the following steps:

[0027] S100. Material preparation: Selenium-enriched jujube and selenium-enriched kiwi fruit after frost are selected as raw materials, the whole fruit is ground or crushed, mixed with water, the ingredients are adjusted, and yeast is inoculated; All the nutrients contained in jujube, such as sugar and bioactive substances, enter the fermentation liquid, and the soluble nutrients in jujube are fully dissolved and enter the fruit wine. The utilization rate of raw materials is high, and the biological activity in jujube is fully utilized ;

[0028] S200, temperature-controlled fermentation: put 70-80% of the volume of the fermenter into the fermenter, control the temperature at 25-32°C, and ferment in the dark for 7-15 days; use static fermentation after adjusting the i...

Embodiment 1

[0042] The concrete production technology of the jujube fermented wine in the present embodiment comprises the following steps:

[0043] Sorting and washing: select mature selenium-enriched jujube and selenium-enriched kiwifruit after frost, remove fruit stems, seeds and impurities, wash and drain;

[0044] Refining and clarification steps: the mass ratio of jujube and kiwi fruit is 10:1. After mixing, directly grind or pulverize to obtain fruit pulp. The mass ratio of fruit pulp to water is 1:4 for batching, and 30 mg of pectin is added per kilogram according to the mass of the batching solution enzymes for clarification;

[0045] Component adjustment steps: add 50 mg of sulfurous acid and 10 g of sugar per kilogram according to the mass of the batching solution; then inoculate 1% Angel Brewery high-activity dry yeast according to the total mass of the feed solution after adding sugar, mix well, and then carry out temperature-controlled fermentation;

[0046] Temperature-con...

Embodiment 2

[0053] The concrete production technology of the jujube fermented wine in the present embodiment comprises the following steps:

[0054] Sorting and washing: select mature selenium-enriched jujube and selenium-enriched kiwifruit after frost, remove fruit stems, seeds and impurities, wash and drain;

[0055] Refining and clarification steps: the mass ratio of jujube and kiwi fruit is 1:1, after mixing, directly grind or pulverize to obtain fruit pulp, mix according to the mass ratio of pulp to water 1:6, add 100mg pectin per kilogram according to the mass of the batching solution enzymes for clarification;

[0056] Component adjustment steps: add 100 mg of sulfurous acid and 18 g of sugar per kilogram according to the mass of the batching solution; then inoculate 5% Angel Brewery high-activity dry yeast according to the total mass of the feed solution after adding sugar, mix well, and then carry out temperature-controlled fermentation;

[0057] Temperature-controlled fermentat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com