A Method of Quickly Correcting the Code Value of Blast Furnace Roof Bus Type Encoder

A technology for encoders and blast furnaces, which is applied in the direction of inspection devices, bells and funnel arrangements, etc., can solve the problems of affecting the re-airing of blast furnaces, spending a lot of time, and affecting the system to a large extent, so as to reduce downtime and wind, shorten the time, The effect of improving efficiency and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention will be discussed in detail below through specific examples.

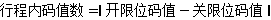

[0023] A method for quickly correcting the code value of the blast furnace roof bus encoder in the present invention is to perform the calibration operation on the basis of the original blast furnace roof bus encoder. The following takes the blast furnace of a steelmaking plant as the background to describe in detail the rapid and automatic correction of the blast furnace furnace The design and the realization process of the method for top bus type encoder code value, automatic correcting encoder code value is divided into two parts in the present invention: 1, distributor α, throttle valve γ angle correction, 2, probe ruler, feeding cart Travel meter correction.

[0024] 1. Angle correction of distributor α and throttle valve γ

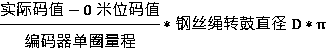

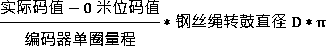

[0025] For example, correcting the distribution angle α of the distributor, the distribution angle α of the distributor is the act...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com