Robotic sewing system, method of operation thereof and method of development of the system

A robot and sewing technology, applied in sewing equipment, leather product sewing machines, program-controlled sewing machines, etc., can solve the problems of low automation level and lack of skills of operators, and achieve the effect of powerful functions, simple interface and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

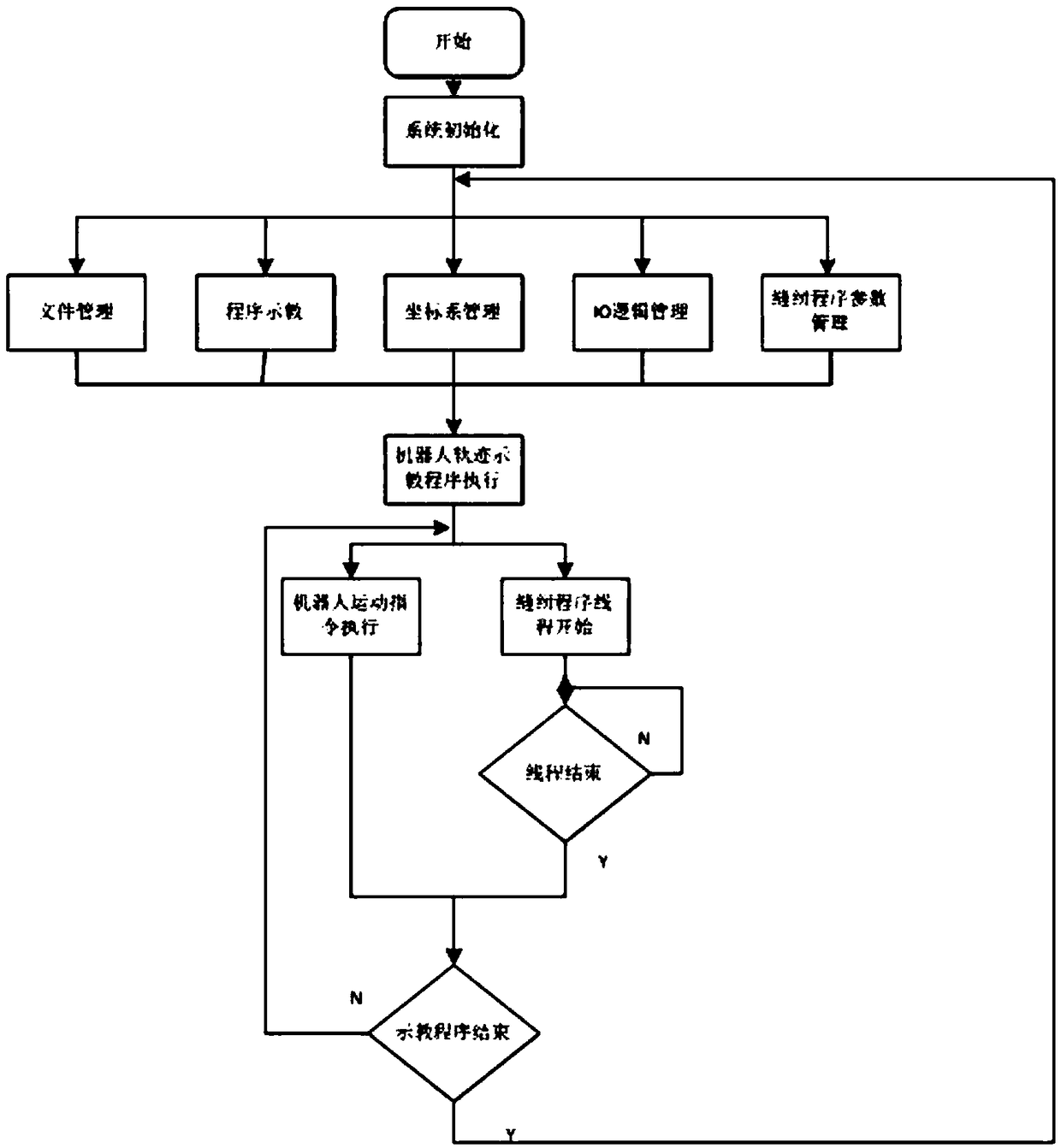

Image

Examples

Embodiment Construction

[0022] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

[0023] The robot sewing system and its operation method and the research and development method of the system. The hardware parts involved in the research and development process are: a 20 kg robot system, a sewing machine driver and a sewing machine. Among them, the 20kg robot system includes a 20kg six-degree-of-freedom robotic arm and an electric control cabinet system. The electric control cabinet system includes a motor driver, a robot controller, an encoder terminal board, a power supply module, a relay module, various terminals, a teaching pendant and the like. In terms of hardware, the sewing machine driver is installed inside the robot electric control cabinet. The sewing machine driver is connected to the robot controller through the encoder terminal board, and the motor drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com