Dry ice granulator

A granulator and dry ice technology, which is applied in the fields of mold extrusion granulation, inorganic chemistry, lighting and heating equipment, etc., can solve problems such as hydraulic oil leakage, feed pipeline blockage, impact of dry ice granulator, etc., and reduce the risk of damage probability, reduce the probability of congestion, and solve the effect of cost waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

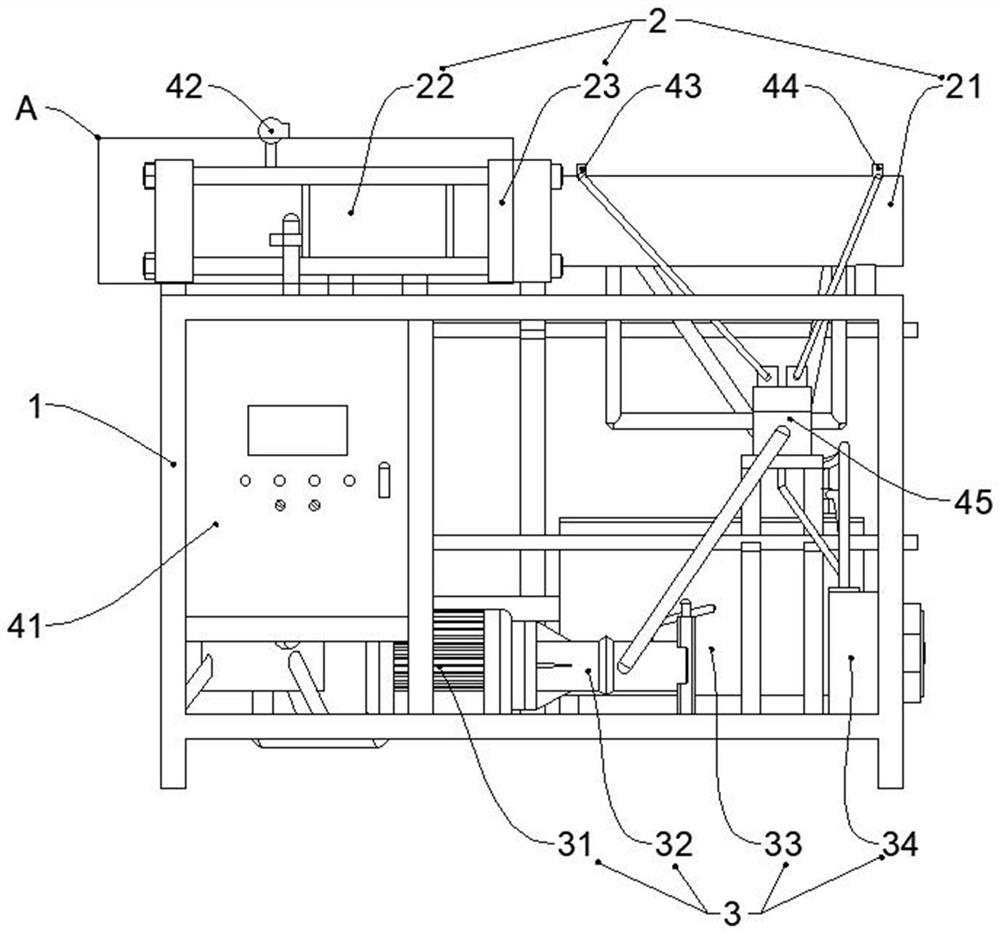

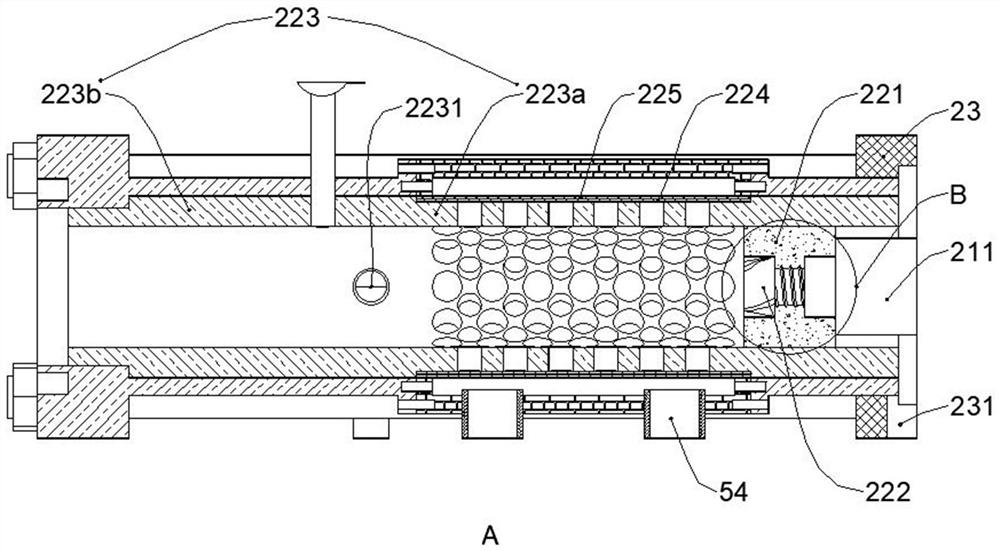

[0033] Such as Figure 1~9 As shown, the dry ice pellet machine provided by the present invention includes a frame 1, on which a compression molding device 2, a hydraulic station 3, an electric control system 4 and a cooling system 5 are arranged, and the compression molding device 2 is symmetrically distributed on the frame 1 Above, the compression molding device 2 includes a power mechanism 21, a working mechanism 22 and a connecting plate 23, the connecting plate 23 is arranged between the power mechanism 21 and the working mechanism 22, and the power mechanism 21, the working mechanism 22 and the connecting plate 23 can be Disassemble the connection together;

[0034] Such as figure 2 As shown, the power mechanism 21 includes a piston push rod 211; the working mechanism 22 includes a piston 221, a fixed bolt 222 and a working chamber 223; and the piston push rod 211 are located in the working chamber 223.

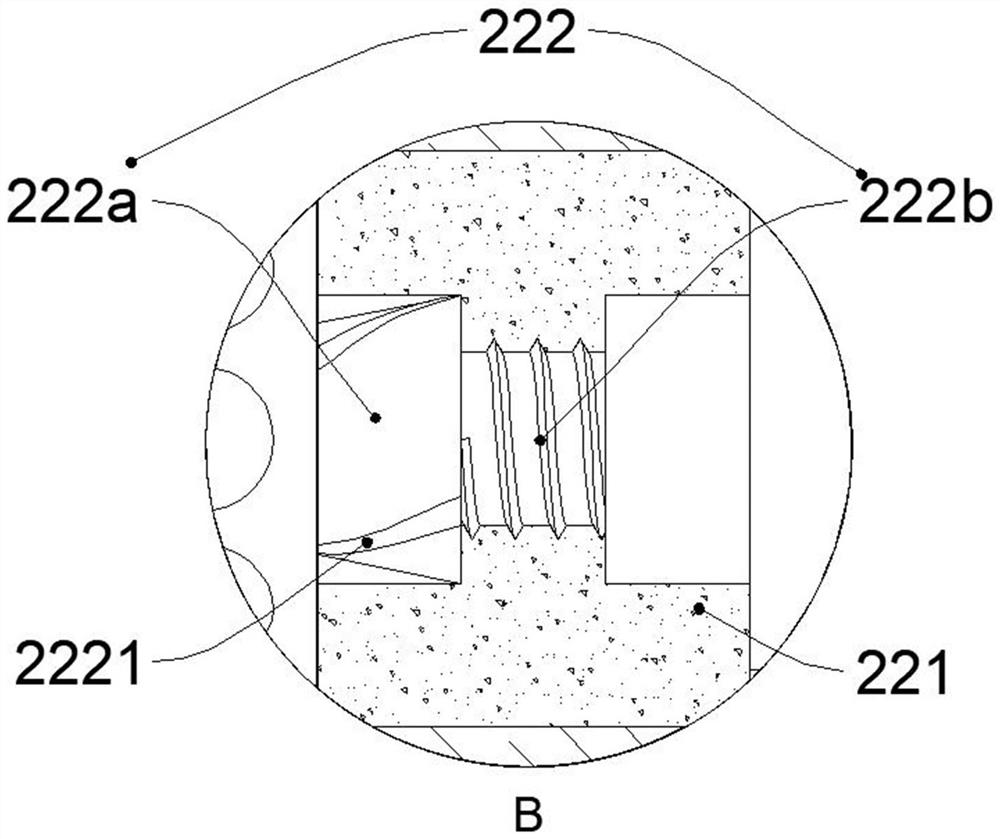

[0035] Such as image 3 As shown, the fixing bolt 222 include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com