Screw-compression piston-pressurization air-cooled integrated air compressor

A screw compression, pressurized and air-cooled technology, which is applied in the direction of liquid variable displacement machinery, rotary piston type/oscillating piston type pump components, liquid fuel engines, etc. Advanced problems, to achieve the effect of improving the workshop environment, reducing pressure drop loss, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

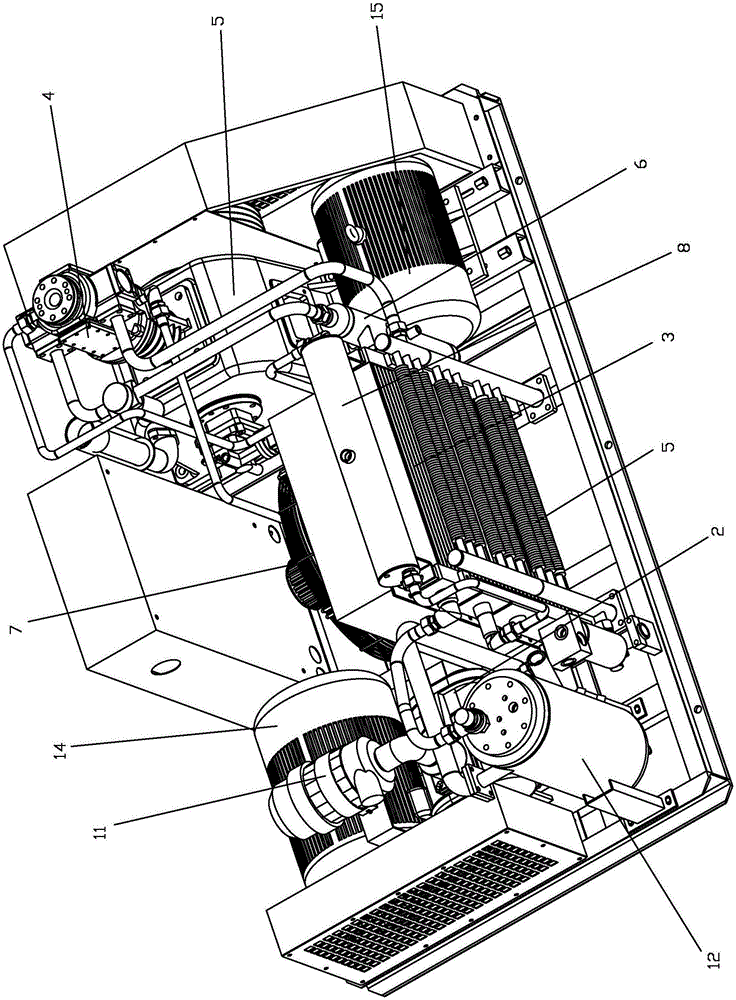

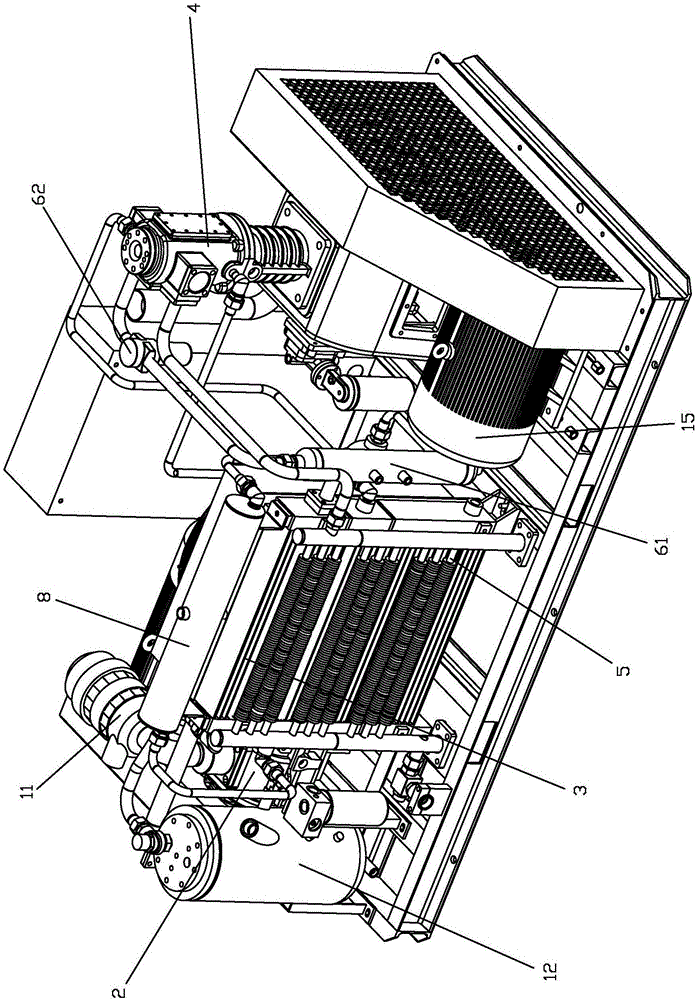

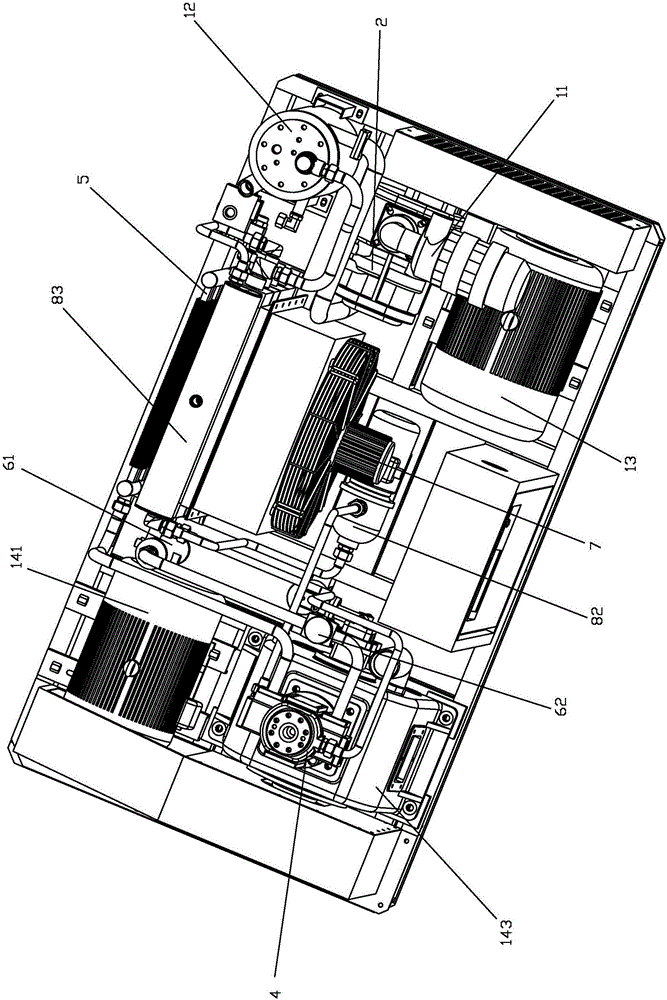

[0038] The screw compression piston supercharged air-cooled integrated air compressor as described in the accompanying drawings, including an air filter 11;

[0039] Screw compression cylinder 2, its intake end is connected with the exhaust end of described air filter 11;

[0040] The first oil-gas separator 12, its intake end is connected with the exhaust end of the screw compression cylinder 2;

[0041]The first cooler 3, its intake end is connected to the exhaust end of the first oil-gas separator 12;

[0042] A double gas-liquid separator 6, the inlet end of which is connected to the exhaust end of the first cooler 3;

[0043] Piston compression cylinder 4, its intake end is connected with the exhaust end of described double gas-liquid separator 6;

[0044] The second cooler 5, its intake end is connected with the exhaust end of the piston compression cylinder 4;

[0045] The first driving mechanism 14 is used to drive the screw compression cylinder 2 to perform primary...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com