Real-time controllable micro-liquid-drop transportation method based on C-shaped cut lithium niobate chip

A technology for cutting lithium niobate and microdroplets, which is applied in the direction of analyzing materials and instruments, can solve the problems of low reliability, complex chip structure, poor regulation of transport action, etc., and achieves high chip reliability, simple chip structure, The effect of flexible control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

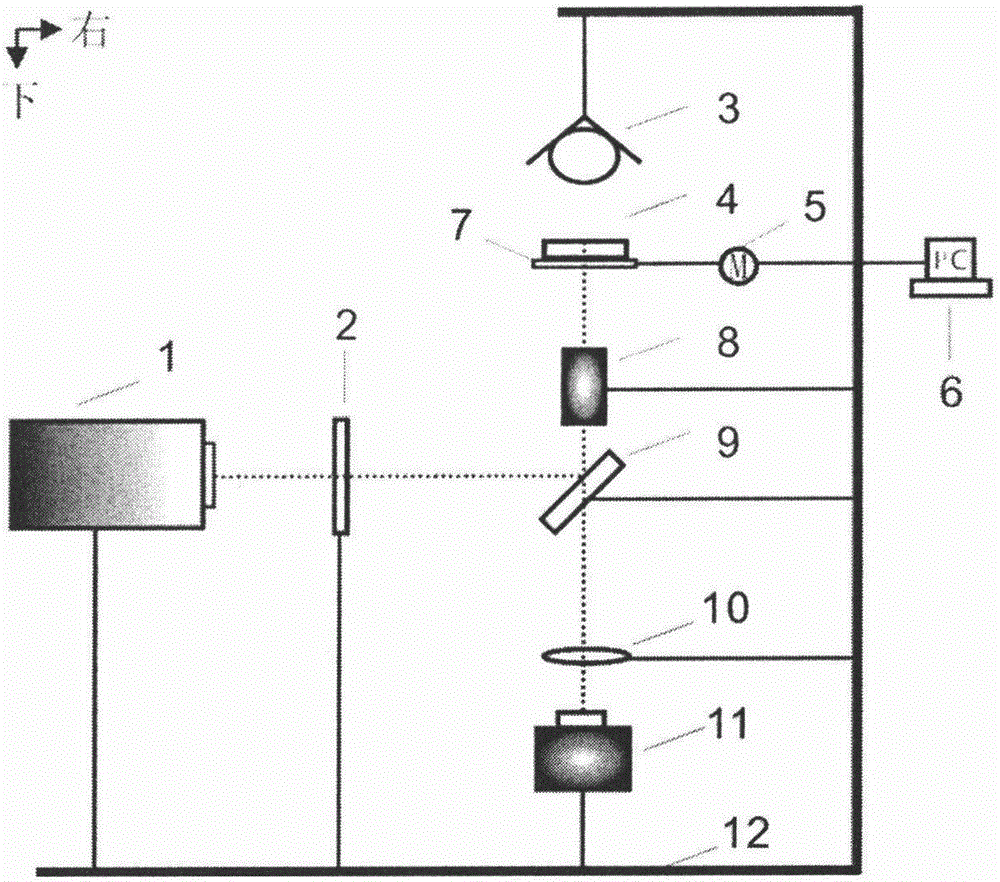

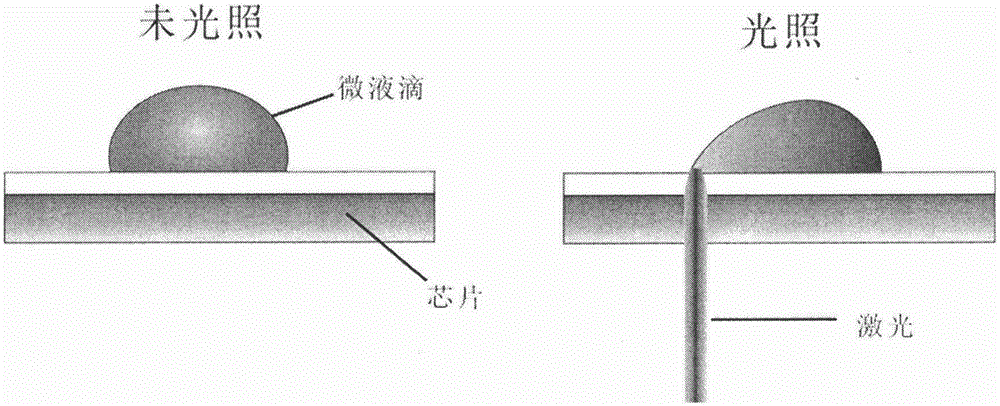

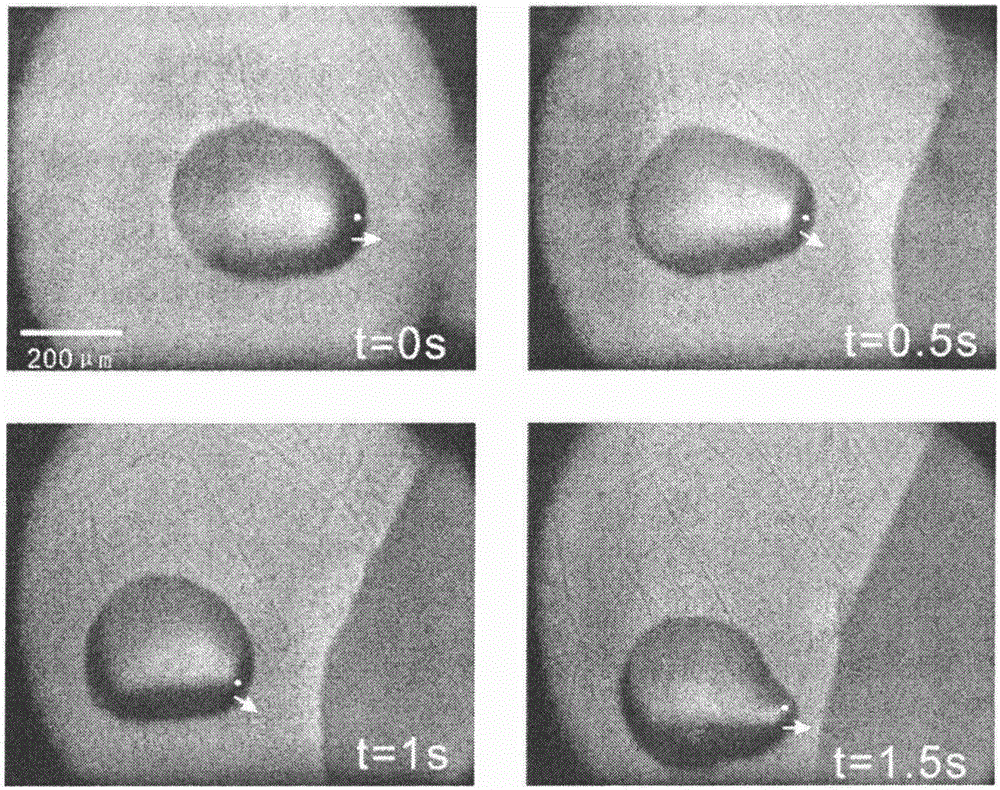

[0029]A laser with a wavelength of 488nm was used, a halogen lamp was selected as the background light source, the magnification of the focusing objective lens was 25 times, and the volume of the micro-droplet (deionized water) to be transported was 0.2 μL. Turn on the laser, adjust the spatial position of the micro-droplet so that the focused spot is located at its edge, and adjust the focused laser power to 15 mW. The movement of the C-cut lithium niobate chip is controlled by the computer, so that the laser spot scans along a certain path on its surface, and the micro-droplets will move together with the laser spot to realize the transport of the micro-droplets, and the transport speed is 133μm / s .

example 2

[0031] A laser with a wavelength of 532nm was used, a halogen lamp was selected as the background light source, the magnification of the focusing objective lens was 25 times, and the volume of the micro-droplet (saline) to be transported was 0.3 μL. Turn on the laser, adjust the spatial position of the micro-droplet so that the focus spot is located at its edge, and adjust the focus laser power to 16mW. The movement of the C-cut lithium niobate chip is controlled by the computer, so that the laser spot scans along a certain path on the surface, and the micro-droplets will move together with the laser spot to realize the transport of the micro-droplets. The transport speed is 33μm / s .

example 3

[0033] A laser with a wavelength of 405nm was used, a white LED light was used as the background light source, the magnification of the focusing objective lens was 25 times, and the volume of the micro-droplet (deionized water) to be transported was 0.1 μL. Turn on the laser, adjust the spatial position of the micro-droplet so that the focus spot is located at its edge, and adjust the focus laser power to 16mW. The movement of the C-cut lithium niobate chip is controlled by the computer, so that the laser spot scans along a certain path on the surface, and the micro-droplets will move together with the laser spot to realize the transport of the micro-droplets, and the transport speed is 153μm / s .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com