LED (light-emitting diode ) lamp bar and backlight module

A technology of LED light strips and LED modules, applied in optics, nonlinear optics, instruments, etc., can solve problems such as evaluation errors, waste of resource costs, development cycle, and failure to share light strips, so as to avoid waste of resources and shorten development cycle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Various embodiments of the invention will be described in more detail below with reference to the accompanying drawings. In the various drawings, the same elements are denoted by the same or similar reference numerals. For the sake of clarity, various parts in the drawings have not been drawn to scale.

[0026] figure 1 A schematic structural diagram of the first embodiment of the LED light bar provided by the present invention.

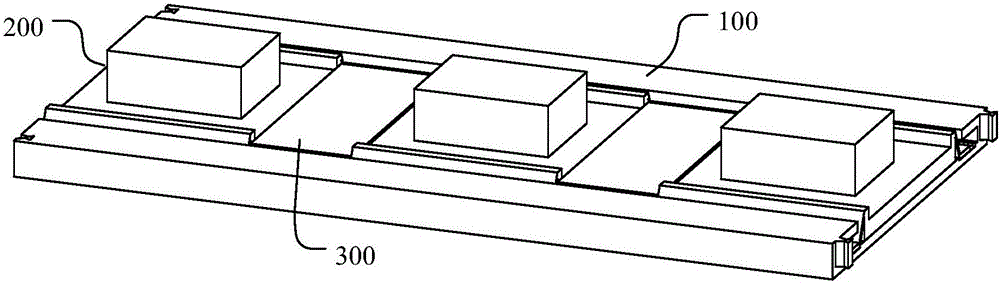

[0027] Such as figure 1 As shown, the LED light bar provided by the present invention includes a substrate 100 , an LED module 200 and a fixing block 300 . There are multiple LED modules 200 . The fixing block 300 is arranged between two adjacent LED modules 200 and fixed on the substrate 100 for controlling the distance between two adjacent LED modules 200 .

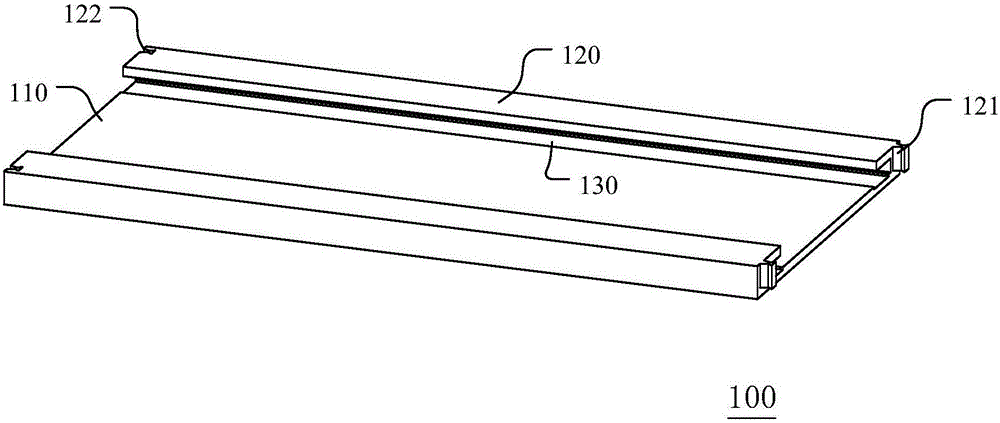

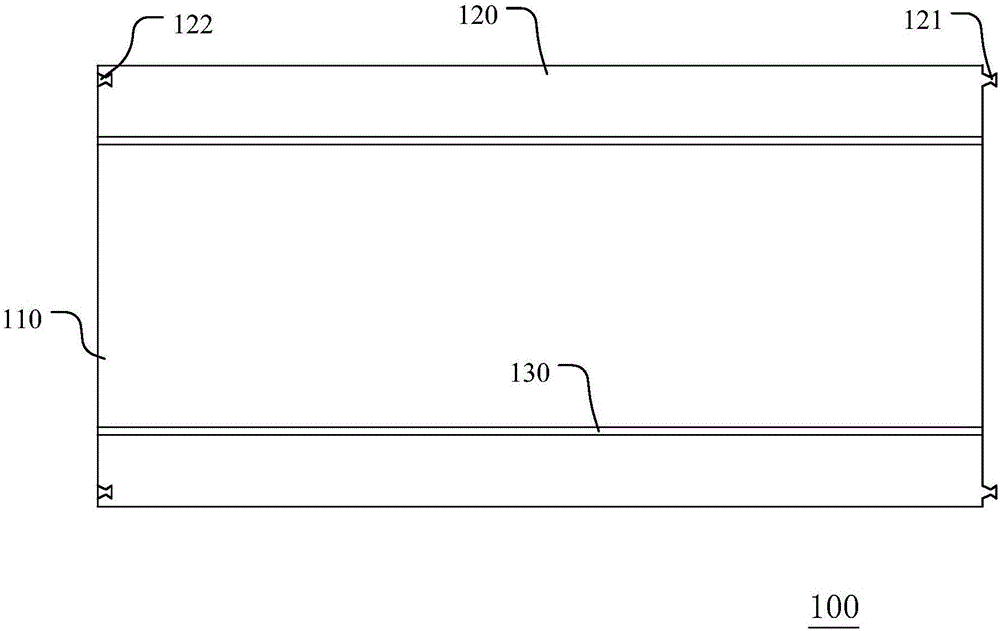

[0028] figure 2 It is a schematic diagram of the substrate structure of the first embodiment of the LED light bar provided by the present invention, image 3 A schematic top view...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com