High-voltage anti-corrosion electrolyte and preparing method and application thereof

An electrolyte and anti-corrosion technology, applied in circuits, electrical components, secondary batteries, etc., can solve problems such as corrosion of active materials and battery accessories, degradation of battery electrochemical performance, and changes in the morphology of positive electrode materials, to optimize the surface of the positive electrode. Film, inhibition of further contact, inhibition of surface activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Cyclic carbonate solvent ethylene carbonate (EC) and linear carbonate solvent ethyl methyl carbonate (EMC) and diethyl carbonate (DEC) are mass ratio EC:EMC:DEC=3:5:2 mixing, and using molecular sieves, calcium hydride, and lithium hydride to purify, remove impurities, and remove water to obtain a mixed solvent;

[0033] (2) At room temperature, the conductive lithium salt LiPF 6 Dissolve in the solvent obtained in step (1), the final concentration is 1.0mol / L, and stir evenly to obtain a common electrolyte;

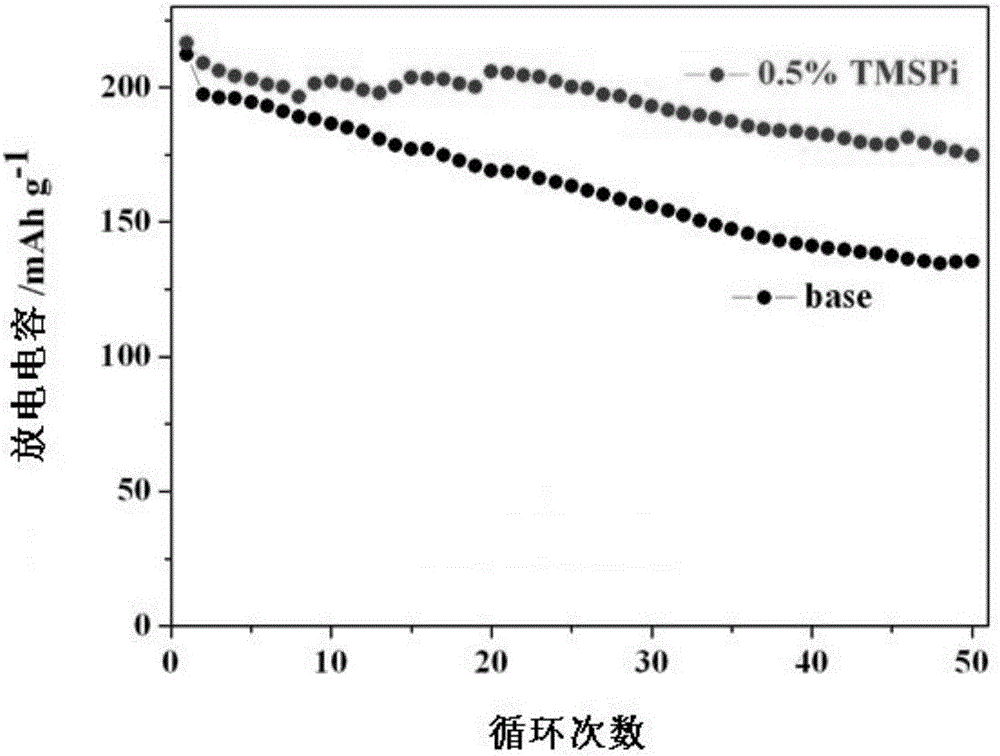

[0034] (3) Add tris(trimethylsilyl) phosphite to the ordinary electrolyte prepared in step (2) (the reagent is purchased from Aladdin, the purity is greater than 96%, and it is used without further purification), tris(trimethylsilyl) phosphite The consumption of base) ester is 0.5% of electrolyte quality, obtains the high-voltage anti-corrosion electrolyte that is used for lithium-ion battery.

Embodiment 2

[0036] (1) Cyclic carbonate solvent ethylene carbonate (EC) and linear carbonate solvent ethyl methyl carbonate (EMC) and diethyl carbonate (DEC) are mass ratio EC:EMC:DEC=3:5:2 mixing, and using molecular sieves, calcium hydride, and lithium hydride to purify, remove impurities, and remove water to obtain a mixed solvent;

[0037] (2) At room temperature, the conductive lithium salt LiPF 6 Dissolve in the solvent obtained in step (1), the final concentration is 1.0mol / L, and stir evenly to obtain a common electrolyte;

[0038] (3) Add tris(trimethylsilyl) phosphite to the ordinary electrolyte prepared in step (2) (the reagent is purchased from Aladdin, the purity is greater than 96%, and it is used without further purification), tris(trimethylsilyl) phosphite The consumption of base) ester is 1% of electrolyte quality, obtains the high-voltage anti-corrosion electrolyte that is used for lithium-ion battery.

Embodiment 3

[0040] (1) Cyclic carbonate solvent ethylene carbonate (EC) and linear carbonate solvent ethyl methyl carbonate (EMC) and diethyl carbonate (DEC) are mass ratio EC:EMC:DEC=3:5:2 mixing, and using molecular sieves, calcium hydride, and lithium hydride to purify, remove impurities, and remove water to obtain a mixed solvent;

[0041] (2) At room temperature, the conductive lithium salt LiPF 6 Dissolve in the solvent obtained in step (1), the final concentration is 1.0mol / L, and stir evenly to obtain a common electrolyte;

[0042] (3) Add tris(trimethylsilyl) phosphite to the ordinary electrolyte prepared in step (2) (the reagent is purchased from Aladdin, the purity is greater than 96%, and it is used without further purification), tris(trimethylsilyl) phosphite The consumption of base) ester is 1.5% of electrolyte quality, obtains the high-voltage anti-corrosion electrolyte that is used for lithium-ion battery.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com