Ingredients for making fermented and dried mutton, and preparation process for fermented and dried mutton

A technology of mutton jerky and craftsmanship, applied in the direction of climate change adaptation, food science, etc., to achieve the effect of reducing mutton taste, strong aroma and appropriate salty taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

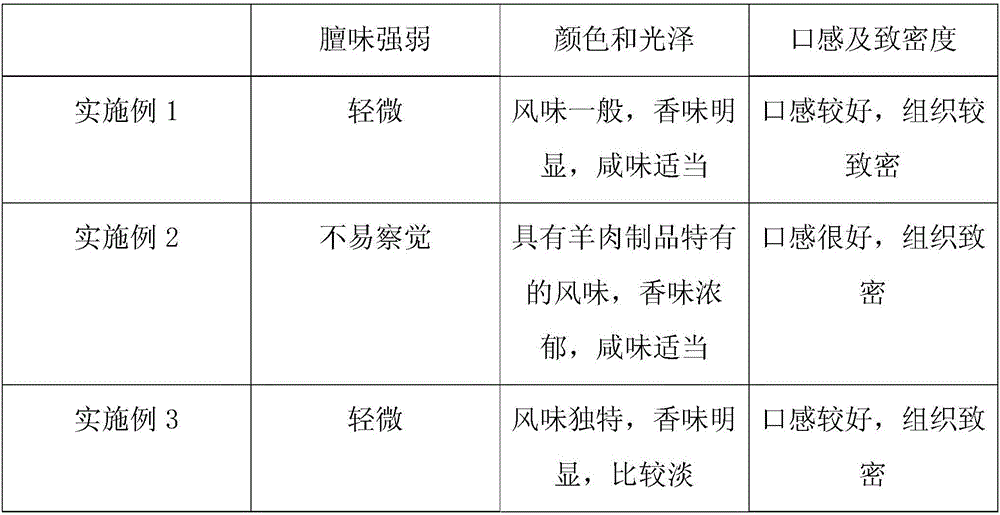

Examples

Embodiment 1

[0020] A manufacturing process of fermented mutton jerky, the ingredients of which are: 3% salt, 2% soy sauce, 1.5% white sugar, 4% spice concentrate, 0.05% sodium nitrate, 0.05% monosodium glutamate, 0.2% pepper, 1% cooking wine , utilize above-mentioned batching to prepare the technology of fermented beef jerky, its concrete steps are:

[0021] (1) Pretreatment of raw materials: select fresh lamb hind legs, remove the skin, bones, fat and tendons, divide them into meat slices of about 0.2kg, wash and drain;

[0022] (2) Fermentation: After draining, put the fresh mutton into the fermentation altar, inject pickle liquid, the ratio of mutton to fermentation liquid is 1:1.5, seal the mouth of the altar with water, control the fermentation temperature at 20°C, and ferment for 10 hours;

[0023] (3) Pre-cooking: Take out the fermented meat pieces and wash them, put them into the pot, add water to completely submerge the meat pieces, and carry out pre-cooking. During the cooking p...

Embodiment 2

[0030] A manufacturing process of fermented mutton jerky, the ingredients of which are: 4% of salt, 3% of soy sauce, 3% of white sugar, 6% of spice concentrate, 0.07% of sodium nitrate, 0.071% of monosodium glutamate, 0.23% of pepper powder, and 1.5% of cooking wine , utilize above-mentioned batching to prepare the technology of fermented beef jerky, its concrete steps are:

[0031] (1) Pretreatment of raw materials: select fresh lamb hind legs, remove the skin, bones, fat and tendons, divide into meat slices of about 0.3kg, wash and drain;

[0032] (2) Fermentation: After draining, put the fresh mutton into the fermentation altar, inject pickle liquid, the ratio of mutton to fermentation liquid is 1:1.5, seal the mouth of the altar with water, control the fermentation temperature at 30°C, and ferment for 12 hours;

[0033] (3) Pre-cooking: Take out the fermented meat pieces and wash them, put them into the pot, add water to completely submerge the meat pieces, and carry out p...

Embodiment 3

[0040] A manufacturing process of fermented mutton jerky, the ingredients of which are: 5% of salt, 4% of soy sauce, 3.5% of white sugar, 8% of spice concentrate, 0.1% of sodium nitrate, 0.1% of monosodium glutamate, 0.25% of pepper powder, and 2% of cooking wine , utilize above-mentioned batching to prepare the technology of fermented beef jerky, its concrete steps are:

[0041] (1) Pretreatment of raw materials: select fresh lamb hind legs, remove the skin, bones, fat and tendons, divide into meat slices of about 0.5kg, wash and drain;

[0042] (2) Fermentation: After draining, put the fresh mutton into the fermentation altar, inject pickle liquid, the ratio of mutton to fermentation liquid is 1:1.5, seal the mouth of the altar with water, control the fermentation temperature at 40°C, and ferment for 14 hours;

[0043] (3) Pre-cooking: Take out the fermented meat pieces and wash them, put them into the pot, add water to completely submerge the meat pieces, and carry out pre-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com