Composite insole with gradient function and making method thereof

A gradient function and insole technology, applied in insoles, footwear, adhesive types, etc., can solve problems such as low moisture absorption, easy slipping when sweating, poor antibacterial and deodorizing properties, and achieve the effect of solving resilience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

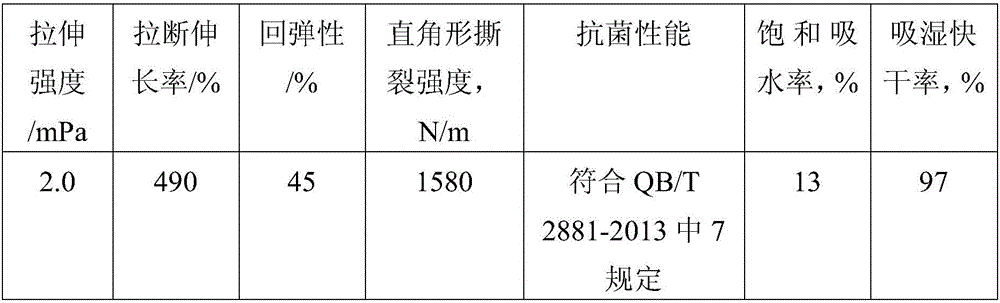

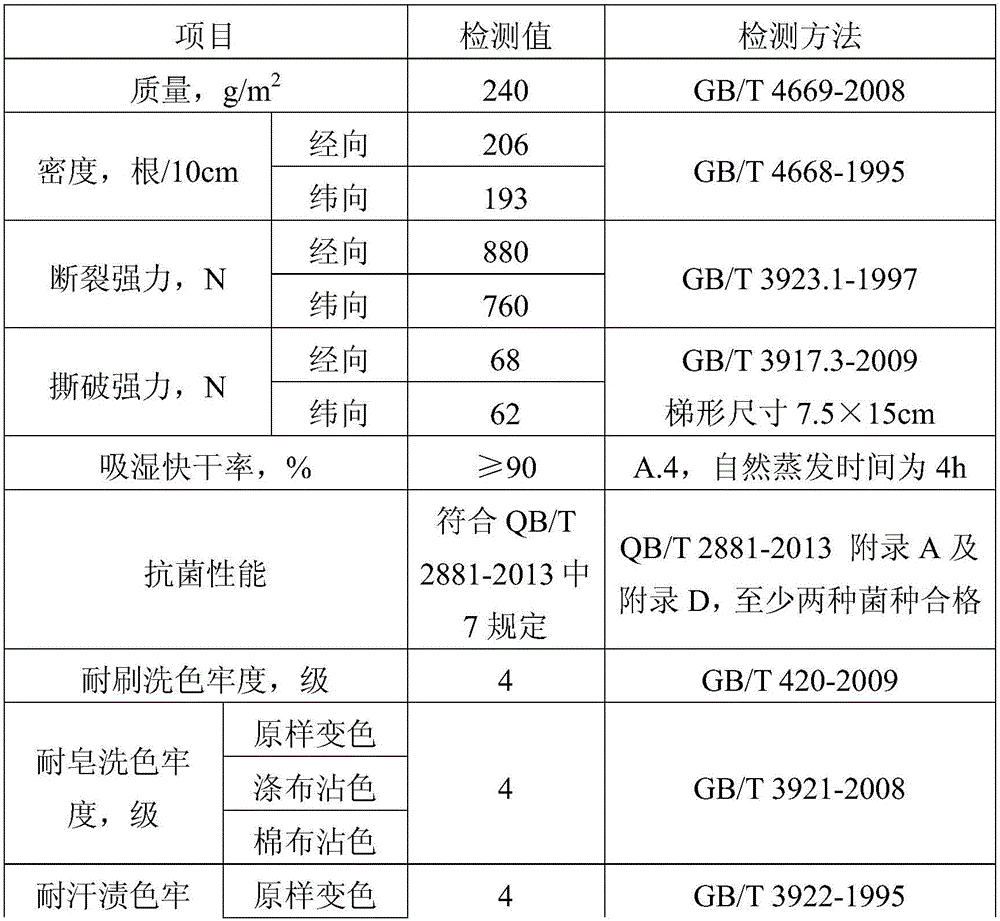

[0071] Embodiment 1, preparation composite insole and performance test thereof

[0072] 1. Preparation of cellulose powder modified polyurethane adhesive

[0073] (1) 120 mass parts of diphenylmethane diisocyanate, 5 mass parts of hemp stalk core powder (particle size is 20 microns), 60 mass parts of 1,4-butanediol-adipic acid copolymerized binary Add alcohol (molecular weight: 1500) and 330 parts by mass of 1,4-butanediol-1,6-hexanediol-adipic acid copolymerized glycol (molecular weight: 2000) into the reactor, and heat up to 85°C for polymerization 1 hour; then, 30 parts by mass of isophorone diisocyanate was added to the reaction system, and a prepolymerization reaction was carried out at 90° C. for 3 hours to obtain a prepolymer.

[0074] (2) Add 10.5 parts by mass of neopentyl glycol and 20 parts by mass of 1,4 butanediol as a chain extender to the prepolymer obtained in the upward step, and carry out a chain extension reaction at 50°C. After 4 hours of reaction, the rea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com